J. Tranter

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 126

- Reaction score

- 0

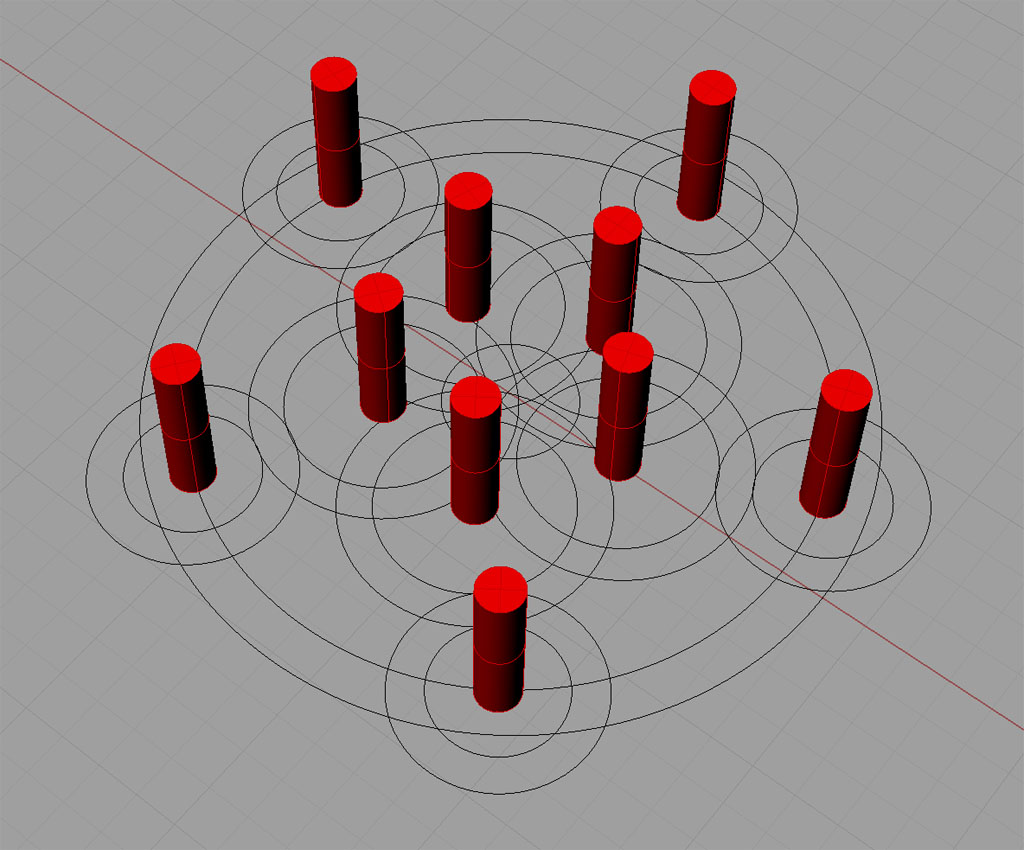

If you didn't have a RT and you wanted to make a spoked flywheel, how would you do it?

John T.

John T.

J. Tranter said:If you didn't have a RT and you wanted to make a spoked flywheel, how would you do it?

John T.

Enter your email address to join: