cl350rr

Well-Known Member

- Joined

- Jun 23, 2009

- Messages

- 198

- Reaction score

- 6

Hello all.

I have a few engines in the "not yet finished" stage and decided that the only way I was going to make the time to finish them any time soon was to sign on here, learn a few things and complete the parts I have been putting off so here we go.

first I am amazed at the tooling, craftsmanship, enginuity, and photography I have seen so far on this forum. I am really not all that blessed in any of these areas so please bear with me...

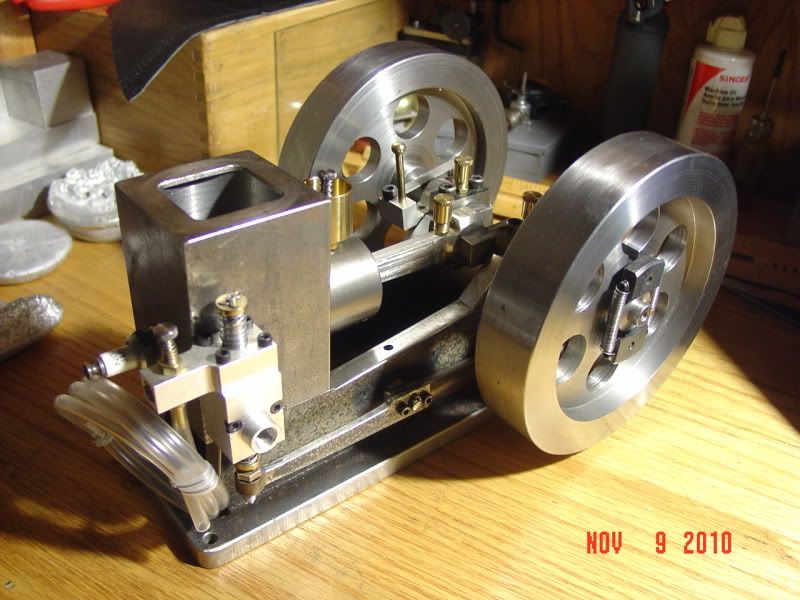

I have been dabbling in machine work for about 30 years now, buying and selling lathes and a milling machine. when I bought my sherline "inside shop" equipment a few years ago, the fellow I bought them from offered me a couple of incomplete engines for a few dollars more. one of the engines was this odds and ends hit and miss engine. he had completed the frame, flywheels, crank, rod, piston, rings and bearings. he handed me the cam gear which is the point he had stopped.

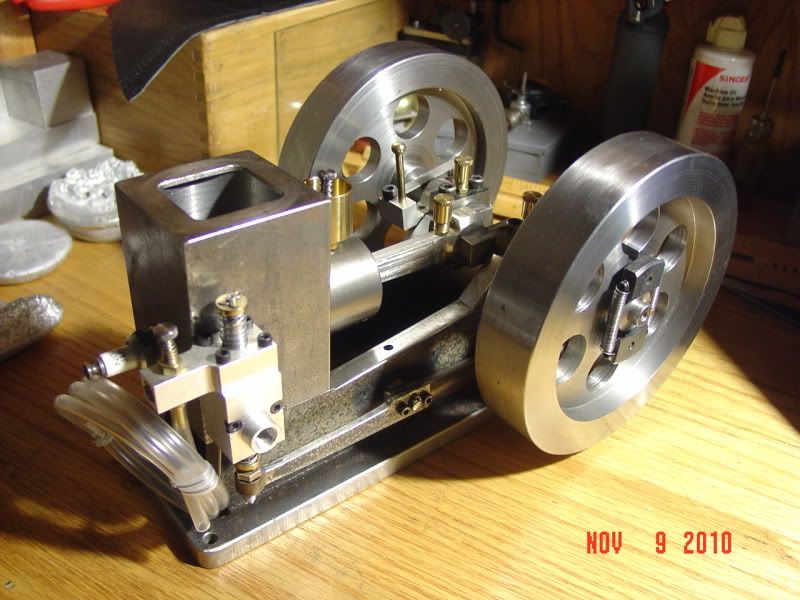

I took it from there and completed a few small parts each winter when I had time. this picture shows where I started this winter's push to complete the engine:

I have a few engines in the "not yet finished" stage and decided that the only way I was going to make the time to finish them any time soon was to sign on here, learn a few things and complete the parts I have been putting off so here we go.

first I am amazed at the tooling, craftsmanship, enginuity, and photography I have seen so far on this forum. I am really not all that blessed in any of these areas so please bear with me...

I have been dabbling in machine work for about 30 years now, buying and selling lathes and a milling machine. when I bought my sherline "inside shop" equipment a few years ago, the fellow I bought them from offered me a couple of incomplete engines for a few dollars more. one of the engines was this odds and ends hit and miss engine. he had completed the frame, flywheels, crank, rod, piston, rings and bearings. he handed me the cam gear which is the point he had stopped.

I took it from there and completed a few small parts each winter when I had time. this picture shows where I started this winter's push to complete the engine: