DICKEYBIRD

Well-Known Member

- Joined

- Sep 27, 2007

- Messages

- 653

- Reaction score

- 46

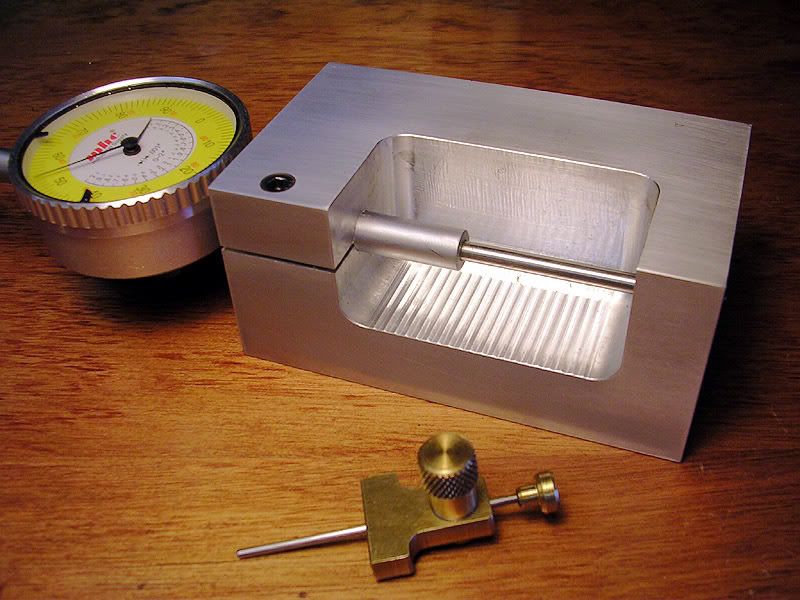

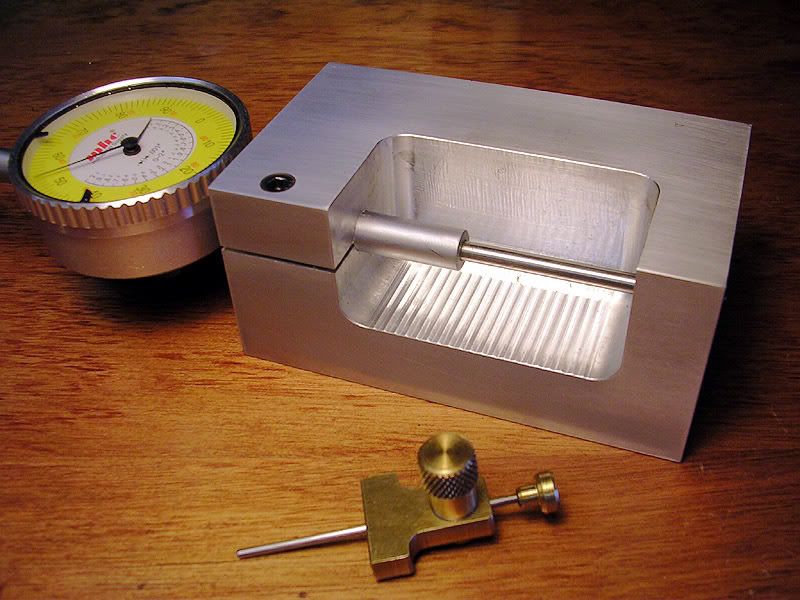

Some time back I built a manual depth gauge per Marv Klotz's method. I've been having trouble measuring the results accurately so I made a fixture for it this morning.

Before ya'll attack me for wasting precious stock, I have to tell you I made it big for a couple reasons. One, I recently acquired a pile of aluminum off-cuts from a friend for almost nothing. Two, I've never done any "pocketing" and was wanting to try it and lastly my new carbide tipped cutoff saw was itching to attack a big chunk of stock.

To use it, I attach a flat tip to the D.I. shaft, clamp it in the fixture with a little bit protruding out the far end; position the tip flush with the face of the fixture with a parallel and zero the dial. When the gauge is pressed in and held square against the face, it gives a direct and accurate reading.

Here's some pics of the little gauge. Ain't it cute? Thanks Marv!

Before ya'll attack me for wasting precious stock, I have to tell you I made it big for a couple reasons. One, I recently acquired a pile of aluminum off-cuts from a friend for almost nothing. Two, I've never done any "pocketing" and was wanting to try it and lastly my new carbide tipped cutoff saw was itching to attack a big chunk of stock.

To use it, I attach a flat tip to the D.I. shaft, clamp it in the fixture with a little bit protruding out the far end; position the tip flush with the face of the fixture with a parallel and zero the dial. When the gauge is pressed in and held square against the face, it gives a direct and accurate reading.

Here's some pics of the little gauge. Ain't it cute? Thanks Marv!