Elmers #33 - Mill Engine

Episode 9

Fiddly Bits

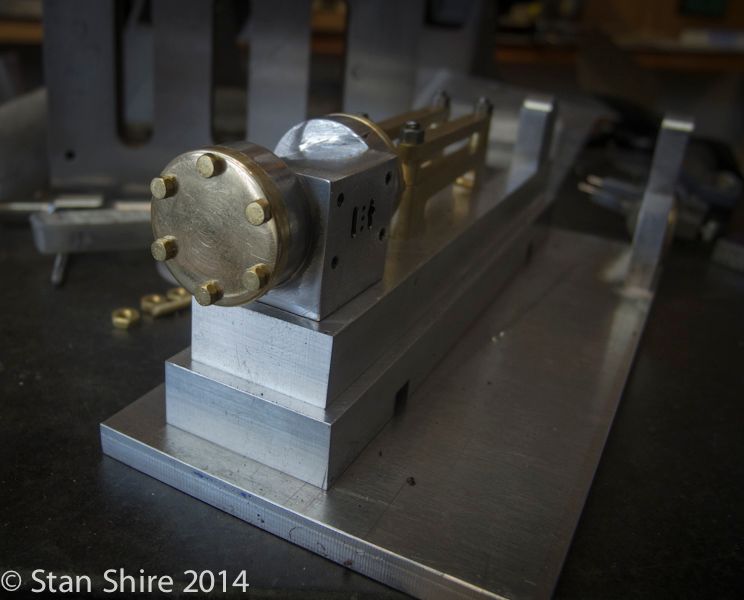

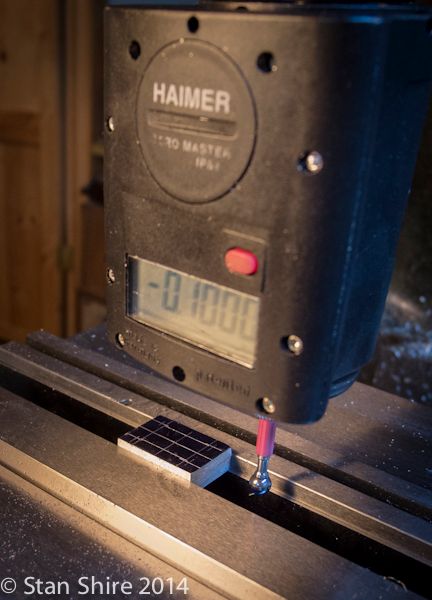

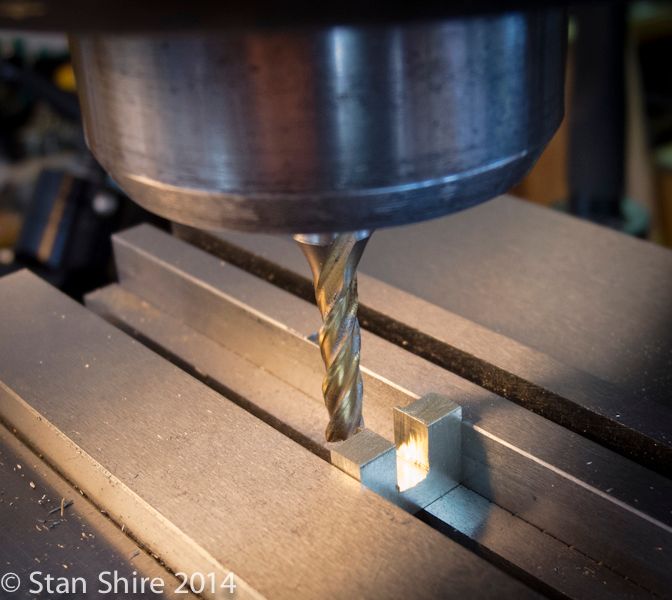

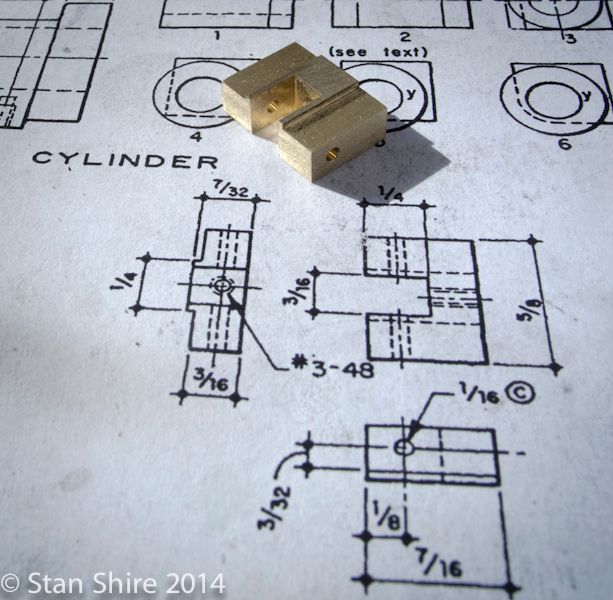

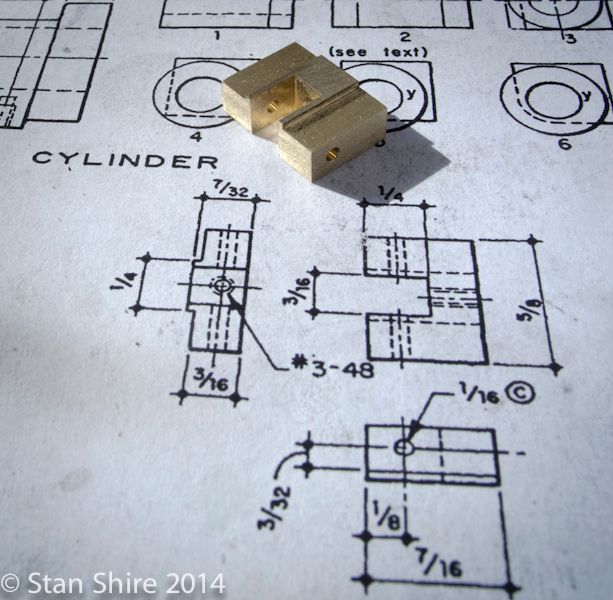

The steam chest has many operations, many of them on tiny parts.

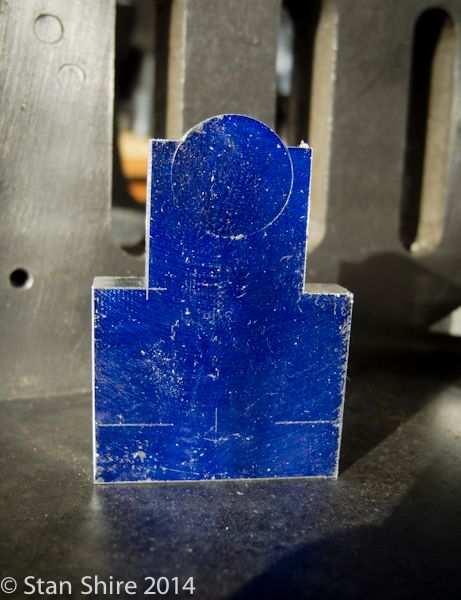

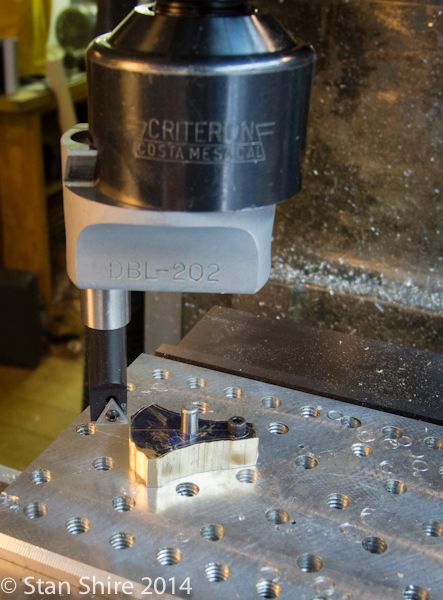

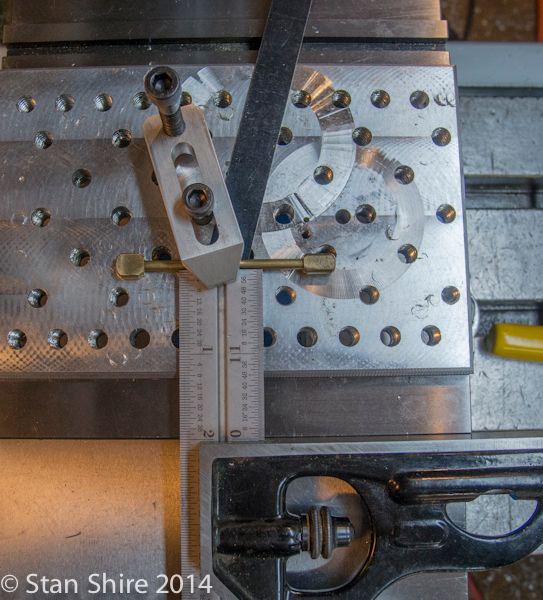

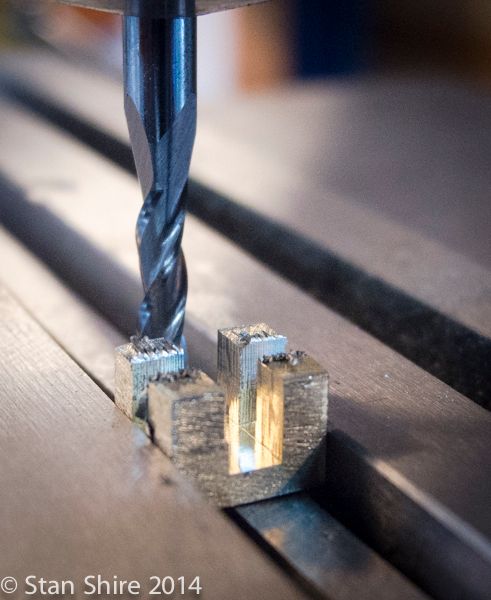

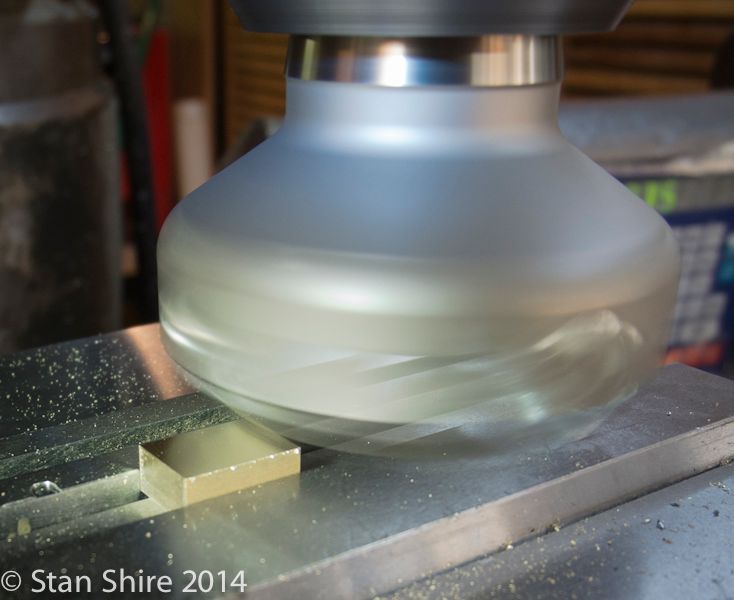

After squaring up the piece for the chest body, I located the centers and then cut through the corners.

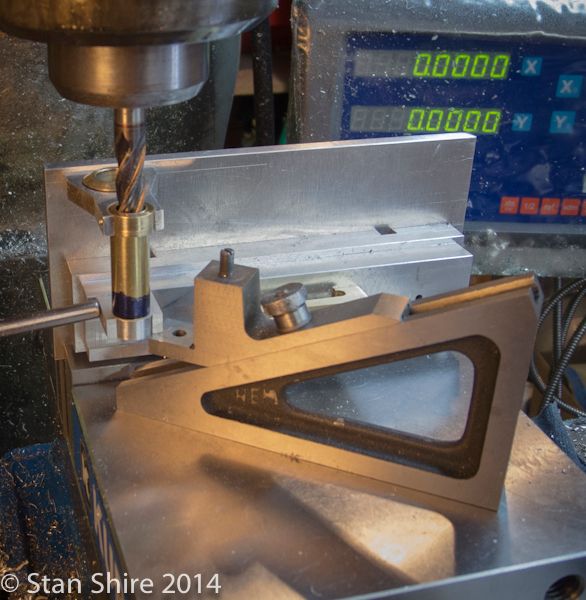

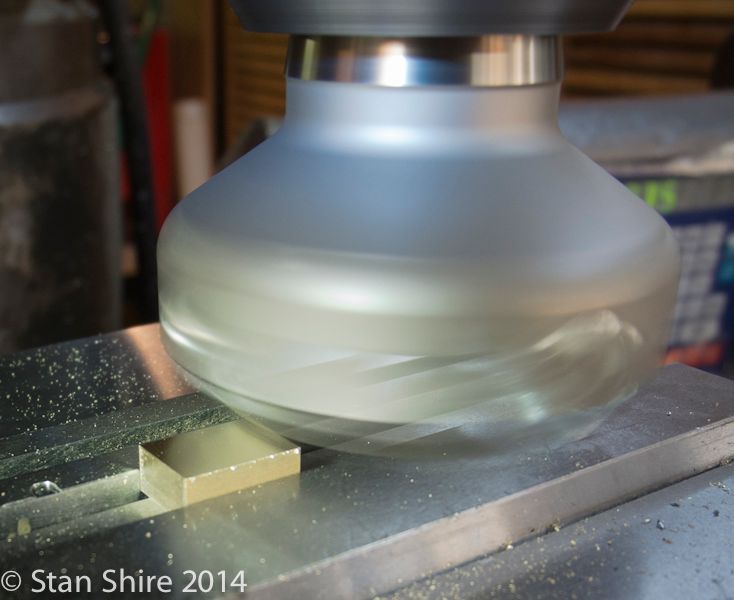

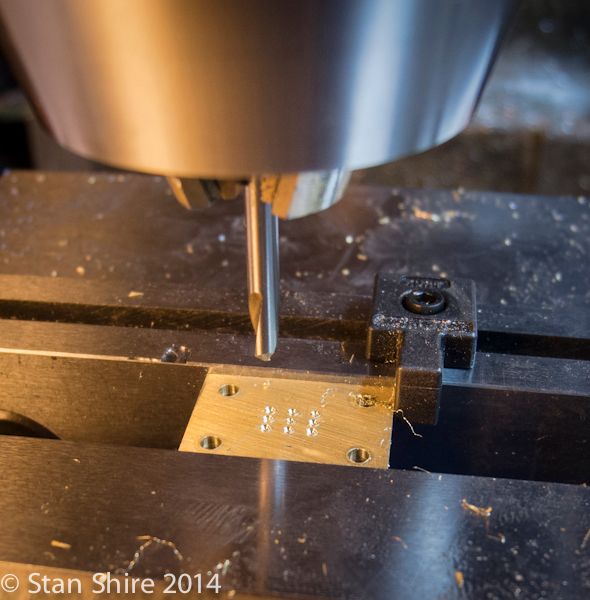

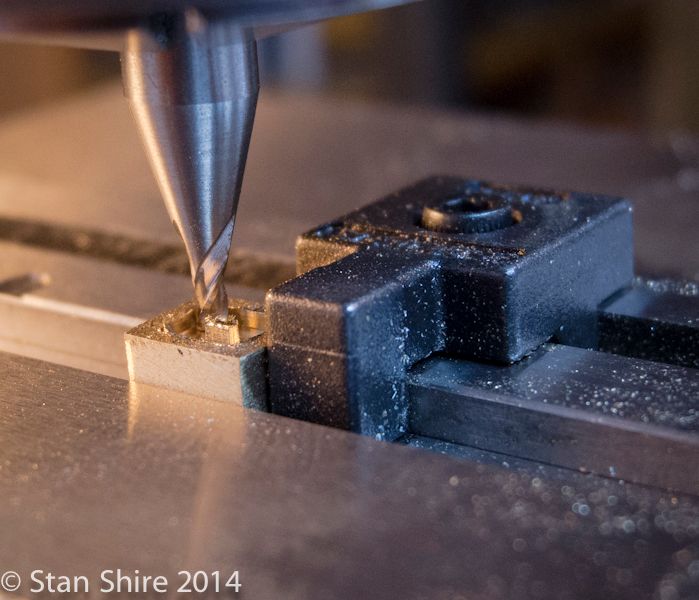

Then, very slowly, with one eye on the part and the other on the DRO, I transformed the inside into chips. The nozzle is blowing air to keep the chips clear. Keeps the end mill from getting jammed up with chips and breaking.

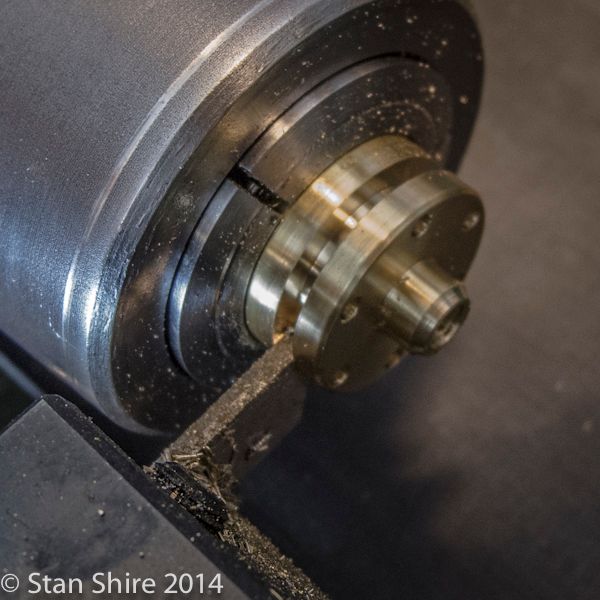

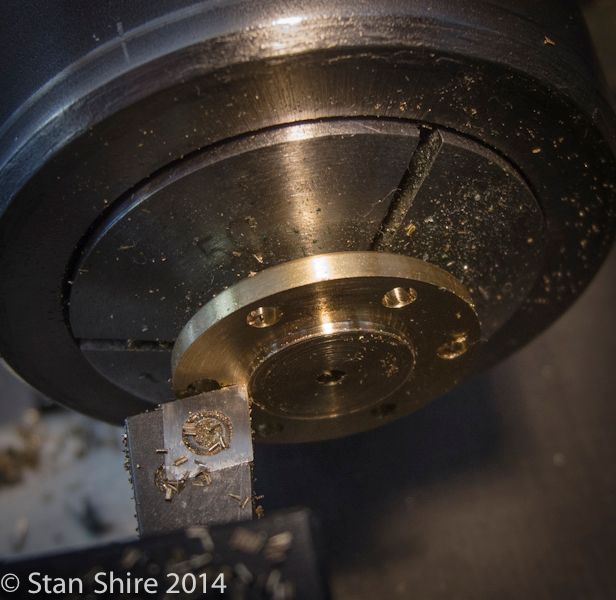

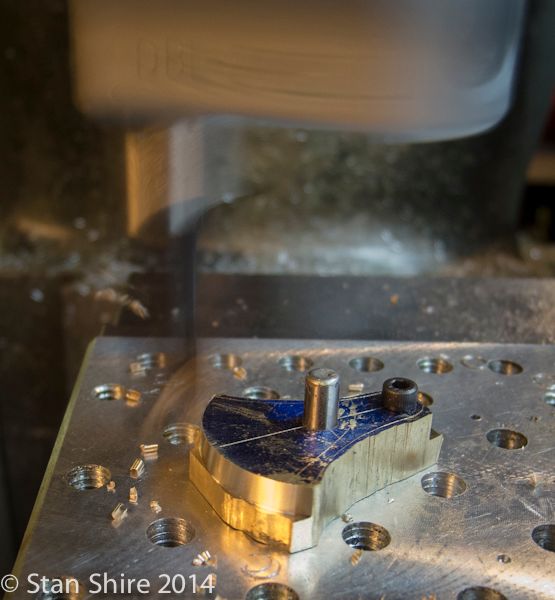

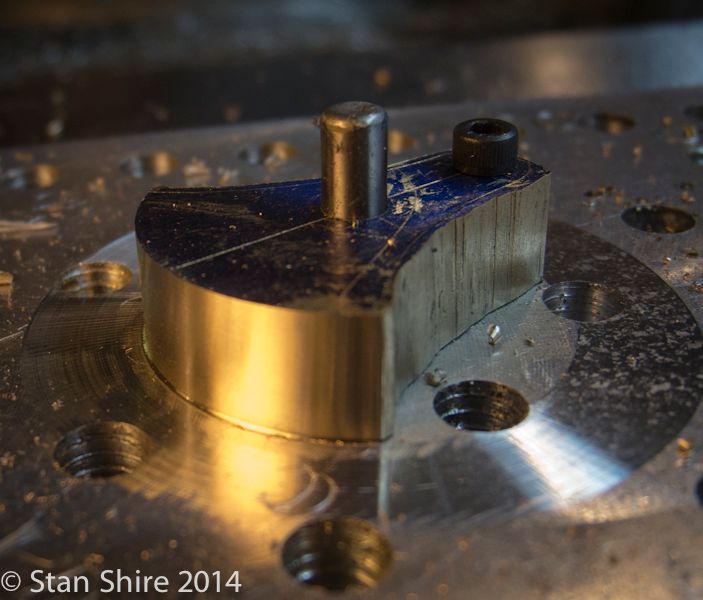

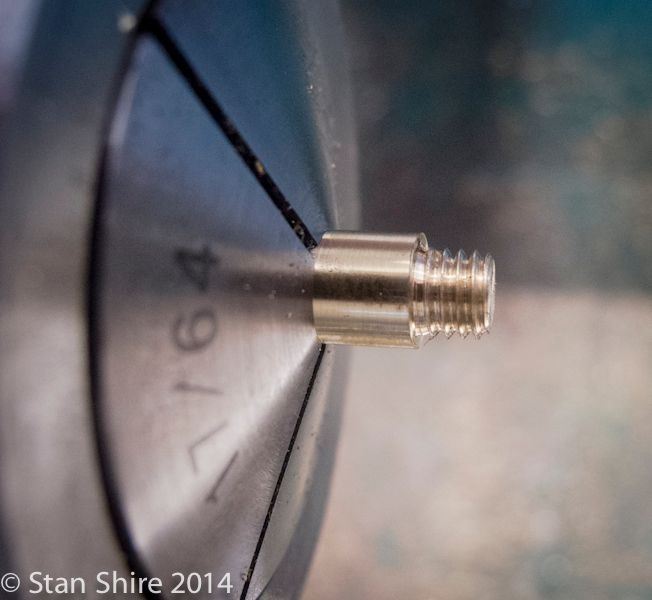

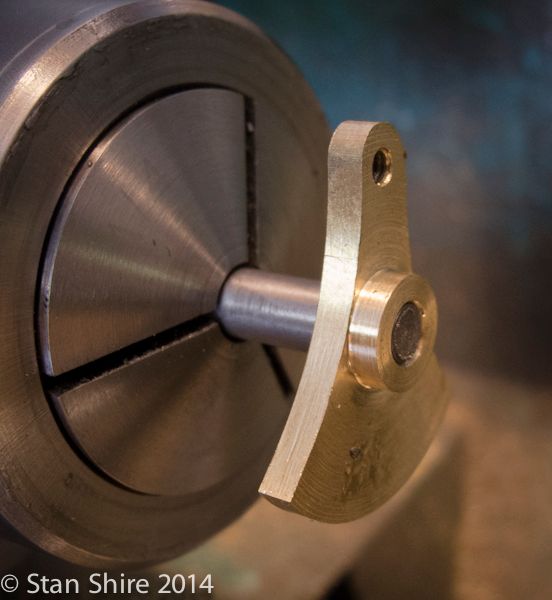

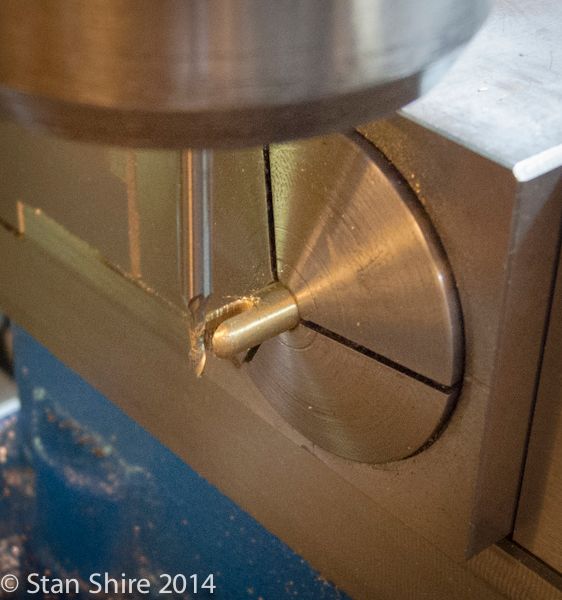

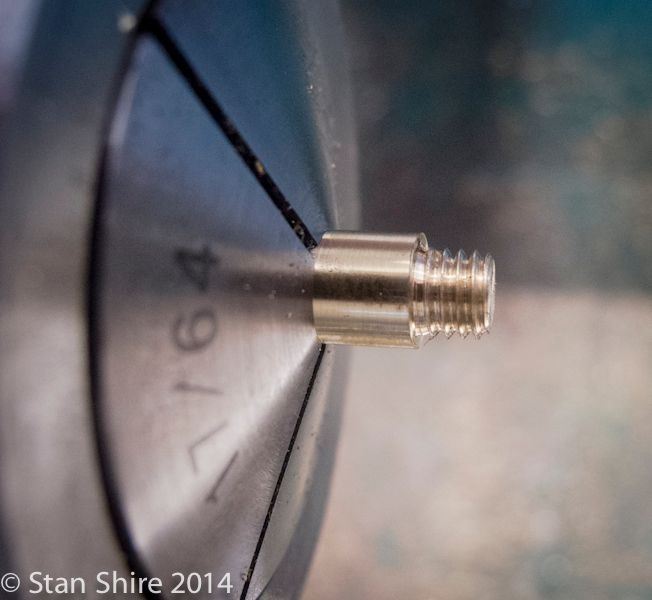

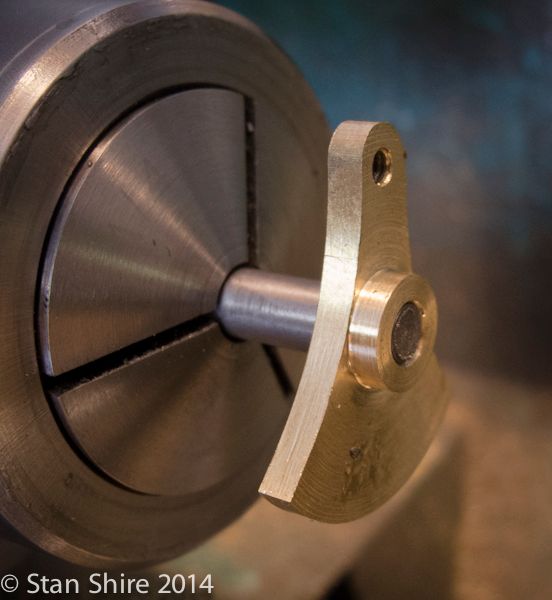

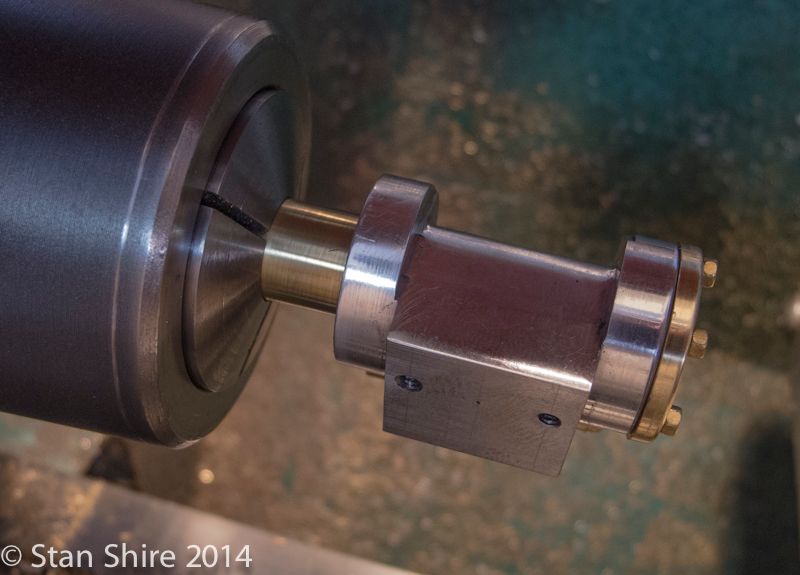

Elmers procedure is to mount the part in a 4-jaw and turn the end bosses (one for the valve rod and pack nut and the other for the rod guide. I did that on the Grasshopper but changed to threaded in bosses on later engines. I liked the contrast of the brass and aluminum.

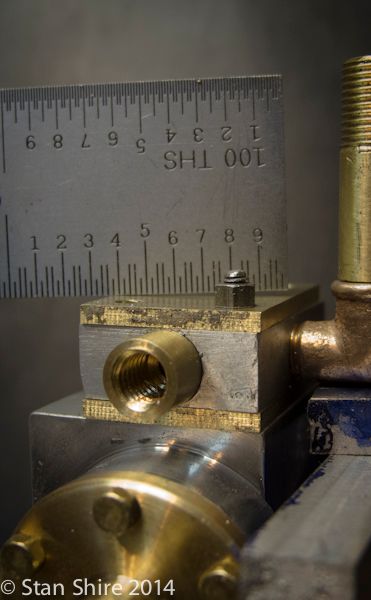

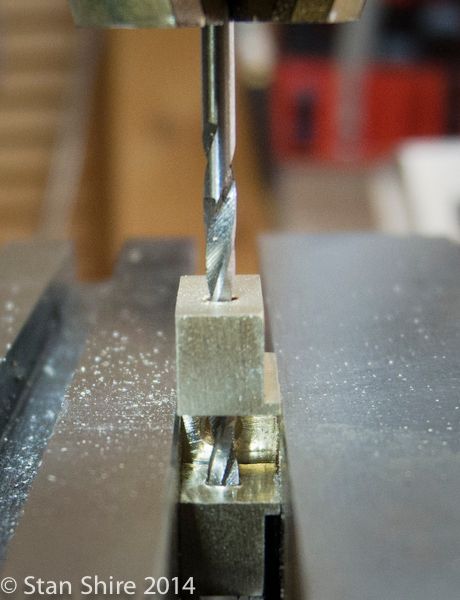

With both bosses threaded and Loctited into the steam chest, I line drilled through both, stopping just short of breaking through the guide boss.

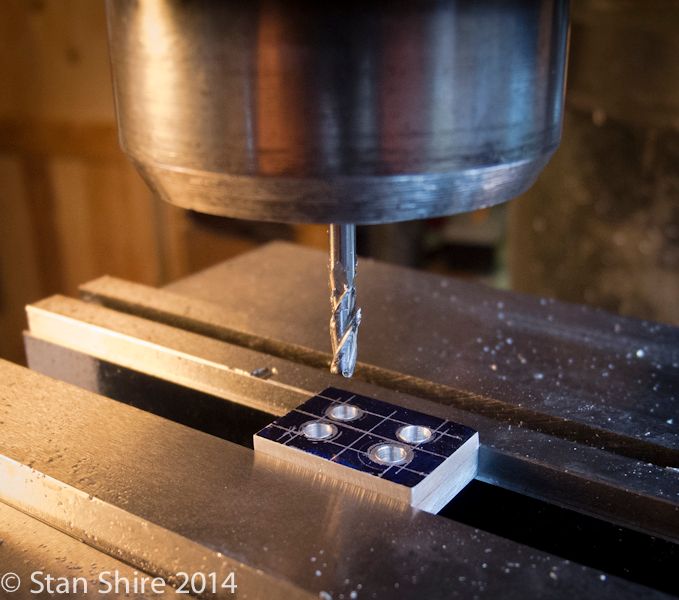

Next are the cover plate and valve plate. Also brass.

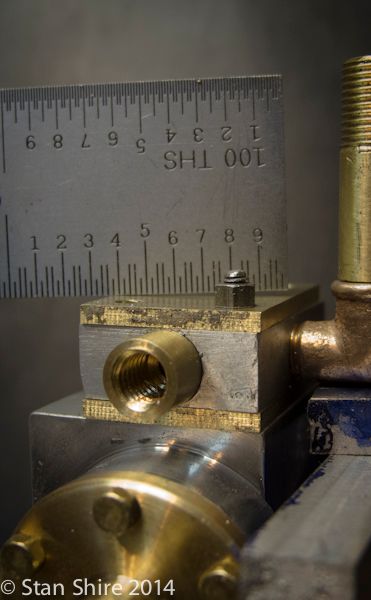

Test fit for alignment. LOOK!! 1.5 threads above the nut.

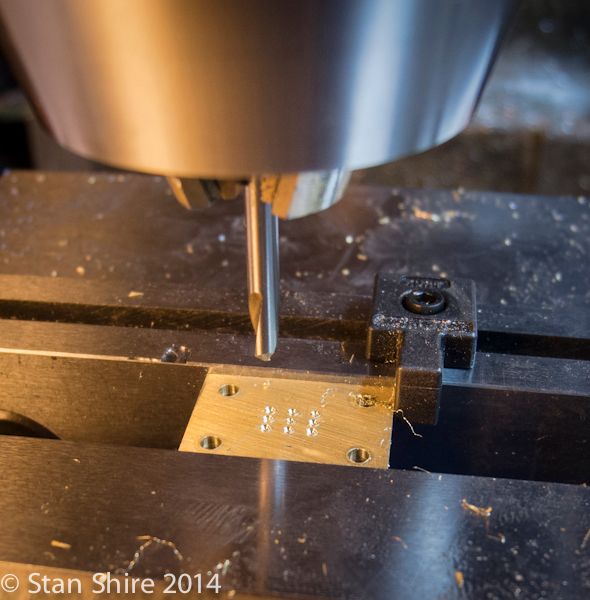

I setup this square bar for the connecting rod and decided to stop there and changed the part to a built-up con rod.

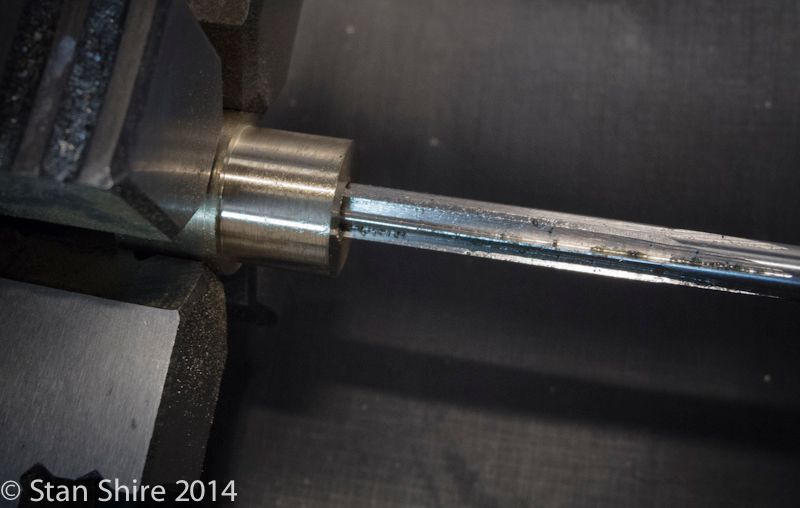

One end of the rod for a test fit.

Both ends ready to go to the mill for flattening the sides and drilling the cross holes.

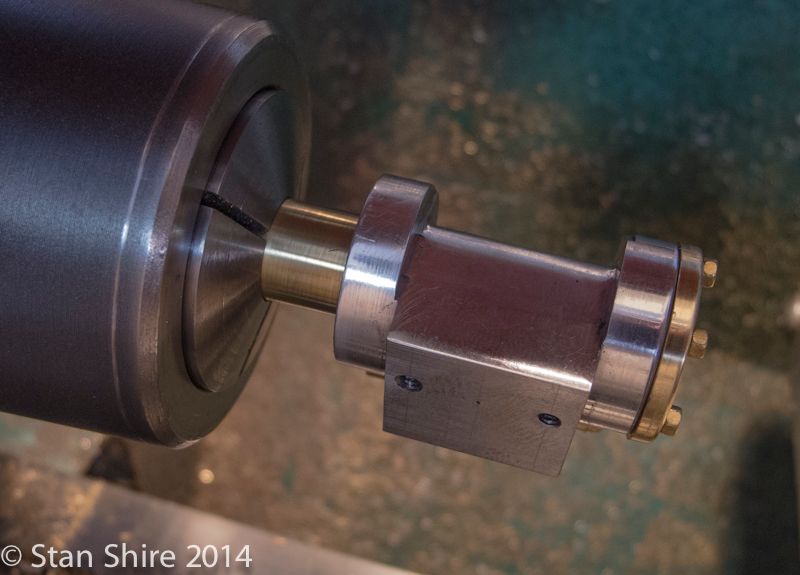

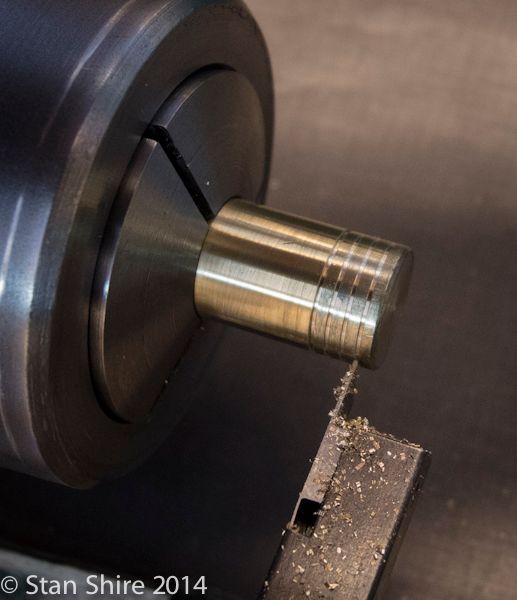

The part in a collet block. A flat was milled, the block was rotated 180 degrees and the opposite flat was milled. I didnt drill the cross holes at this time because I wanted to wait until the ends were Loctited and cured. That way, the holes will be aligned. Elmers plans have the hole dimensions center-to-center.

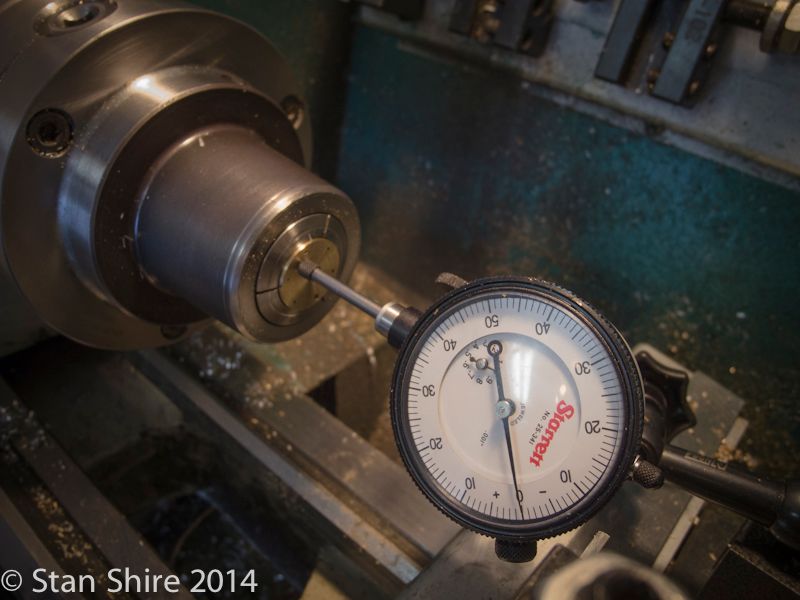

Back at the lathe, The parts were reversed and cut to finished length.

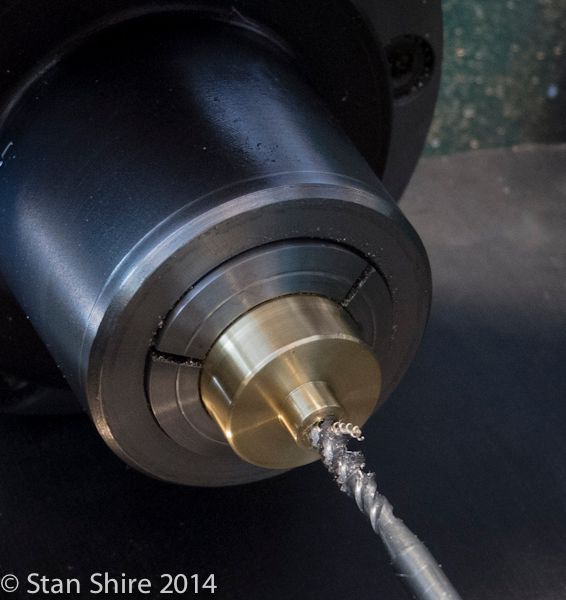

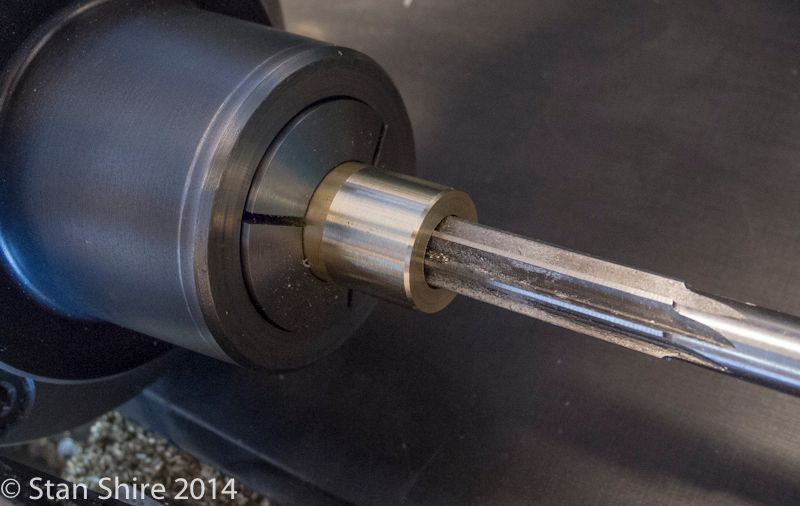

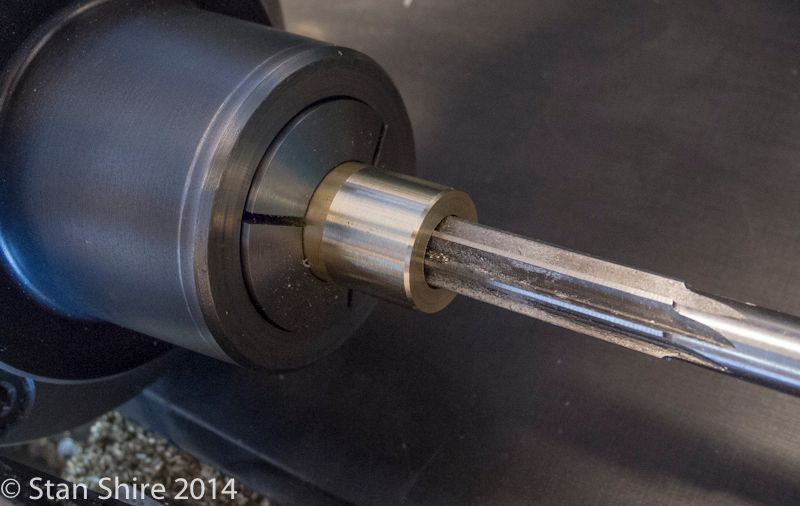

Then bored for the rod.

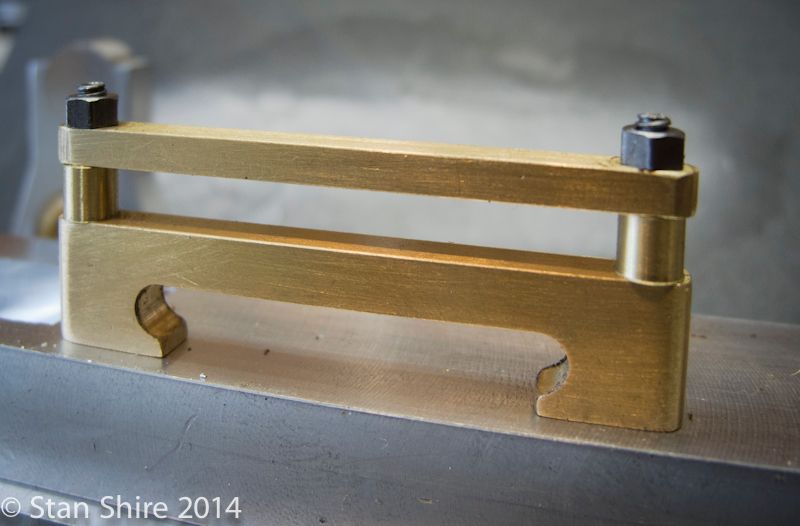

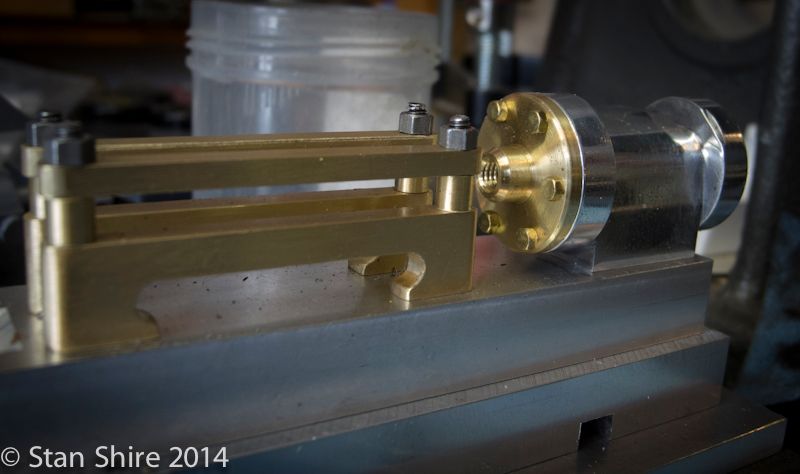

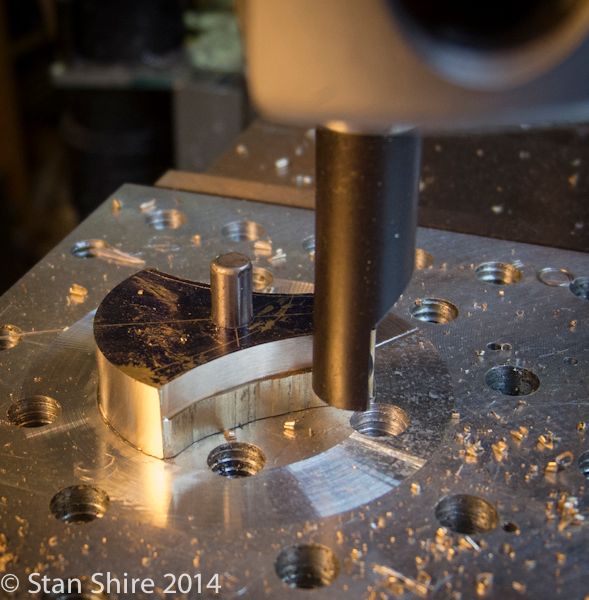

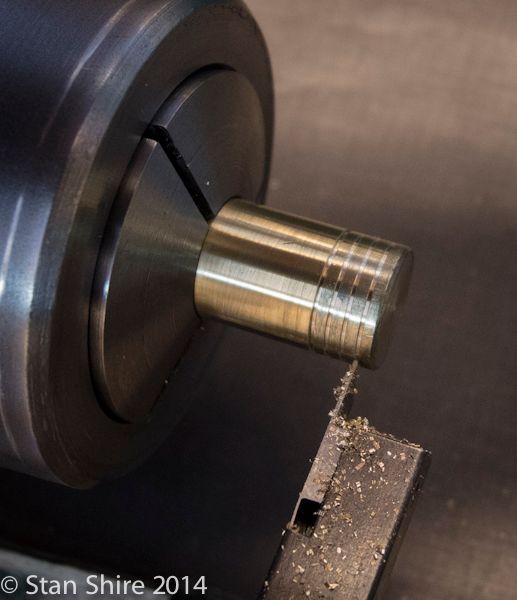

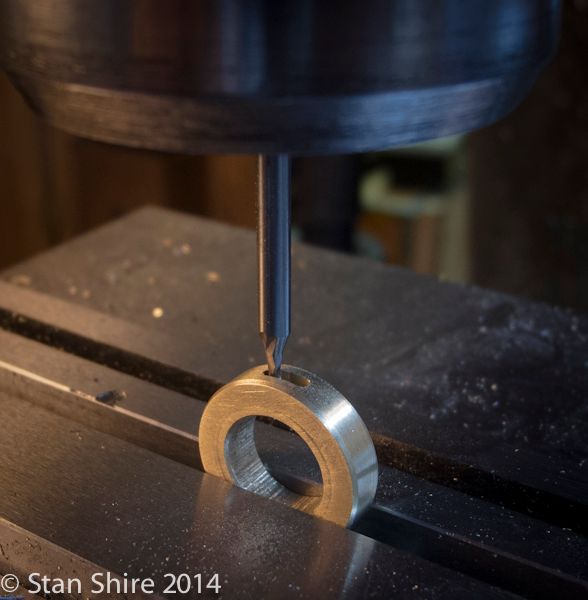

On to the Eccentric strap. Turned and bored at the lathe and then a .0625 slot was cut.

The strap was milled and both pieces were silver soldered.

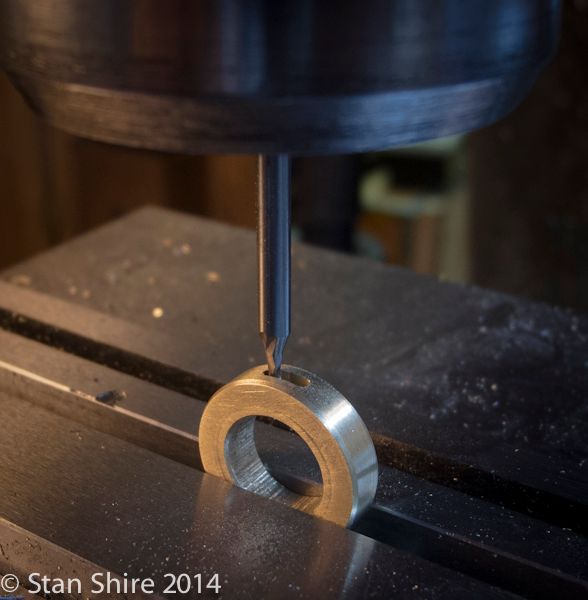

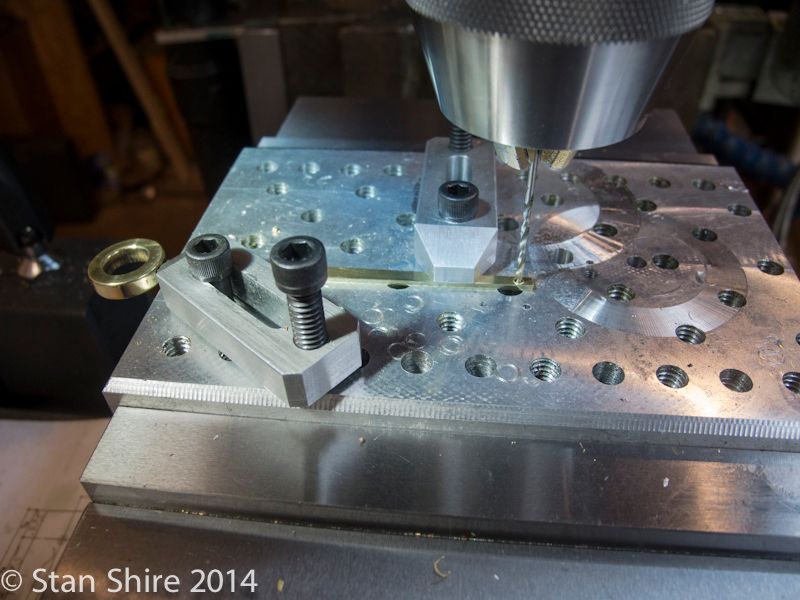

I located the center of the large hole, moved to Elmers dimension and drilled the other hole.

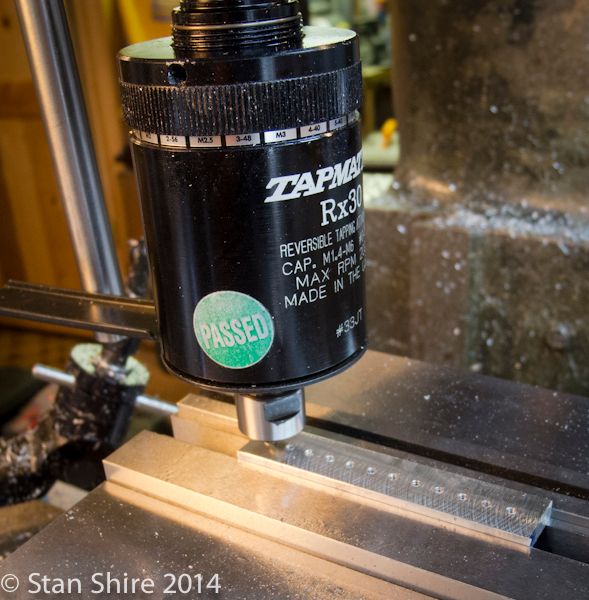

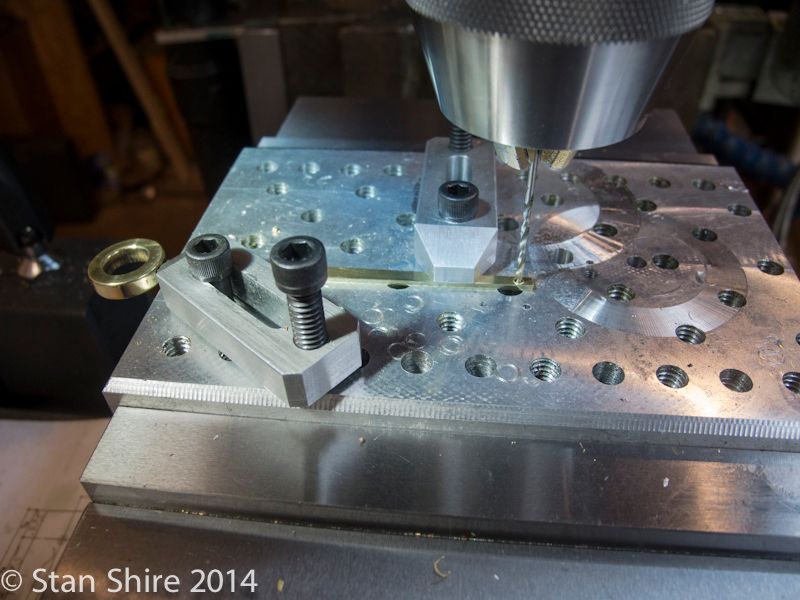

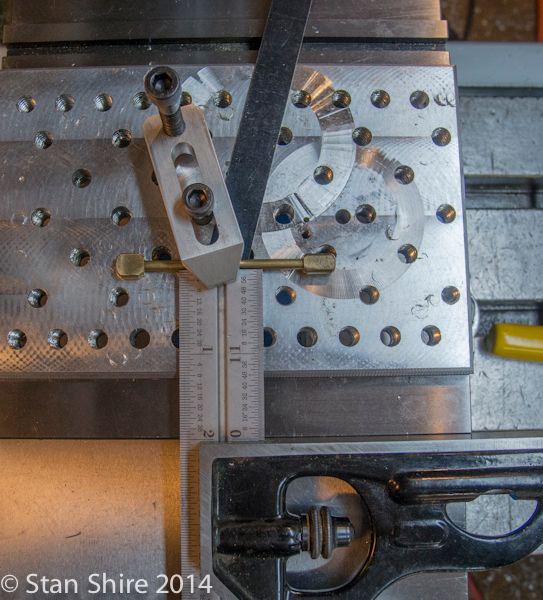

Then to the drilling on the connecting rod. I used the square to get the part parallel to the x-axis. I next ran a DTI along the rod to fine tune the parallelism. and drilled.

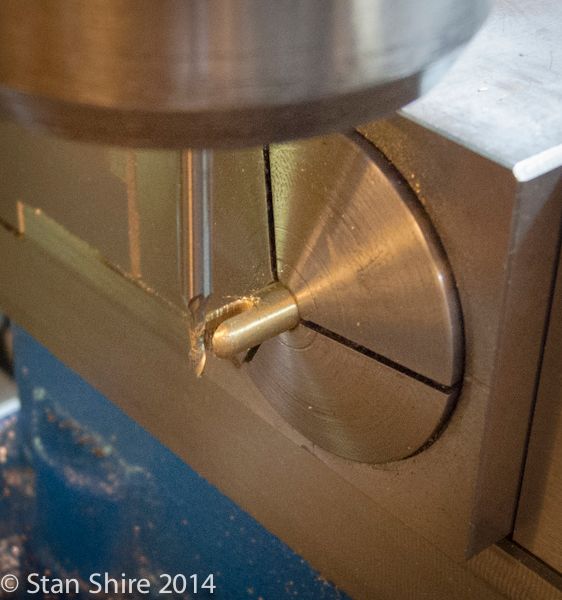

A test fit of the eccentric on the shaft.

And the final fit of the piston in the cylinder.

The piston has 3 oil grooves, .005 deep.

Then, drilling and tapping the piston and threading the piston rod. They were then Loctited together.

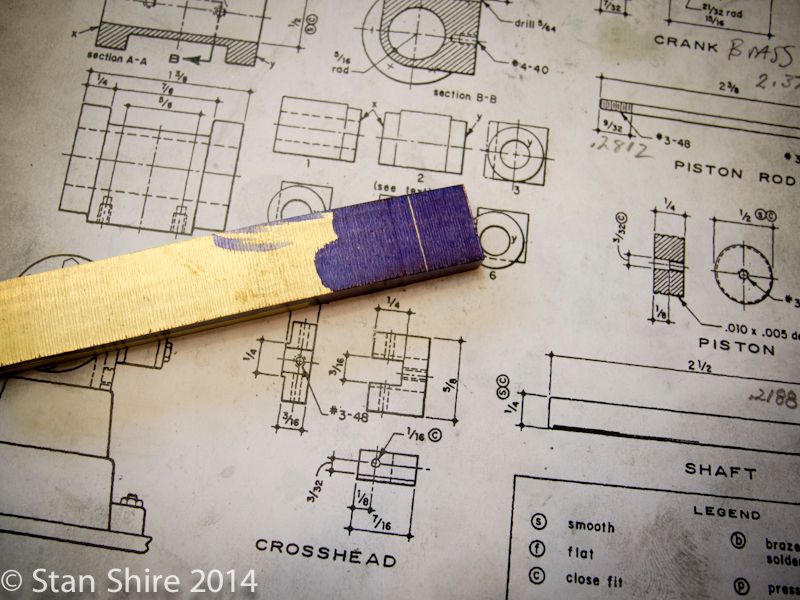

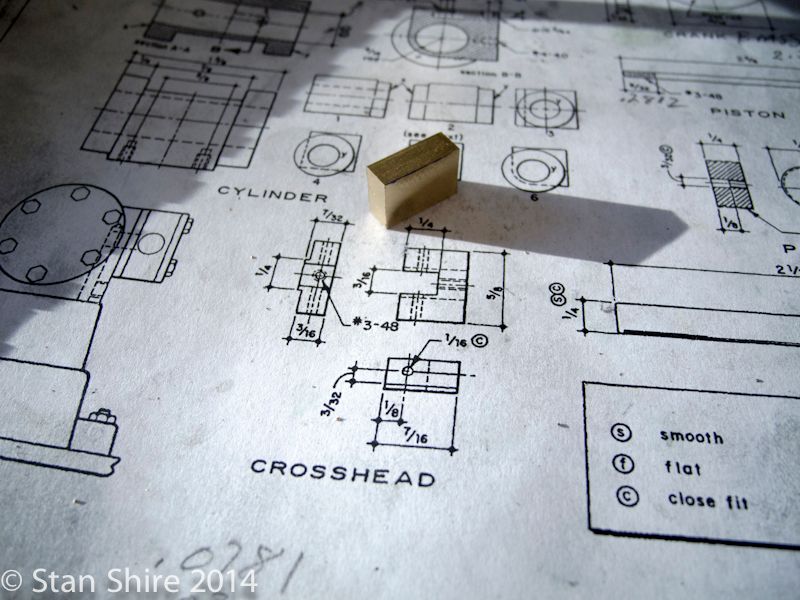

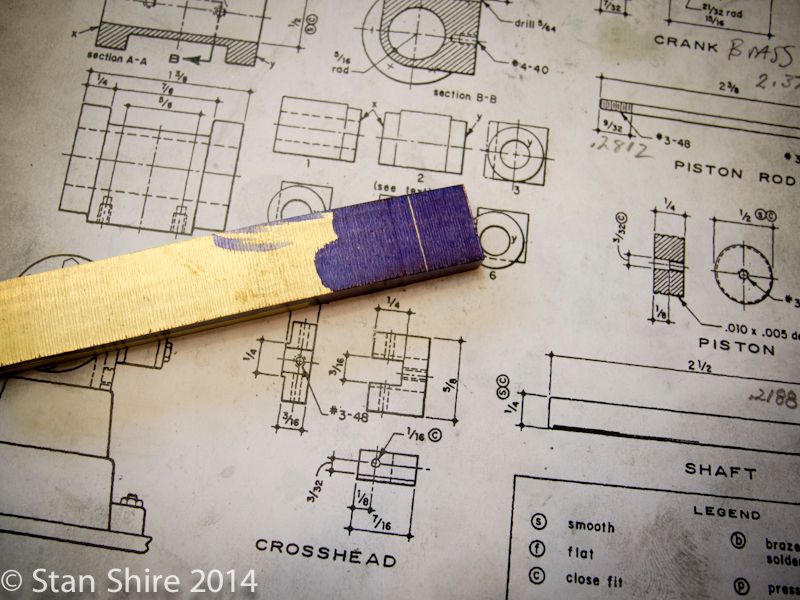

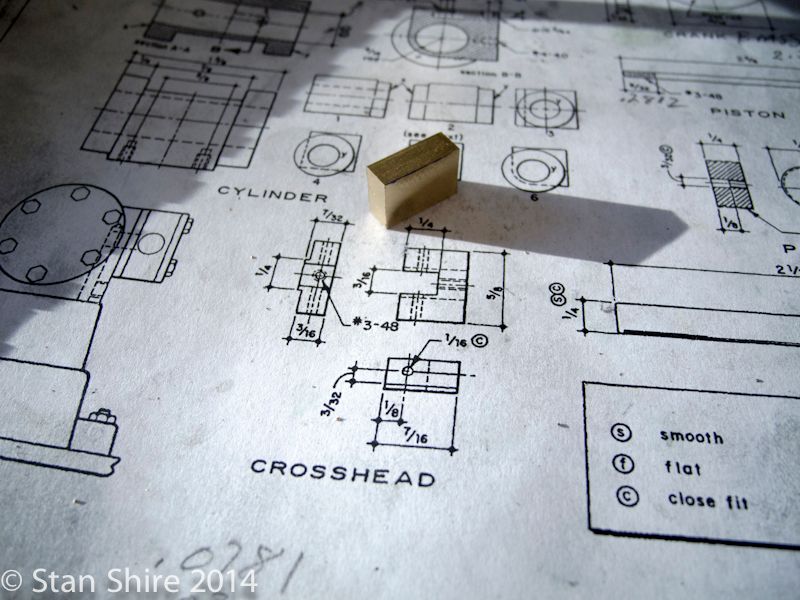

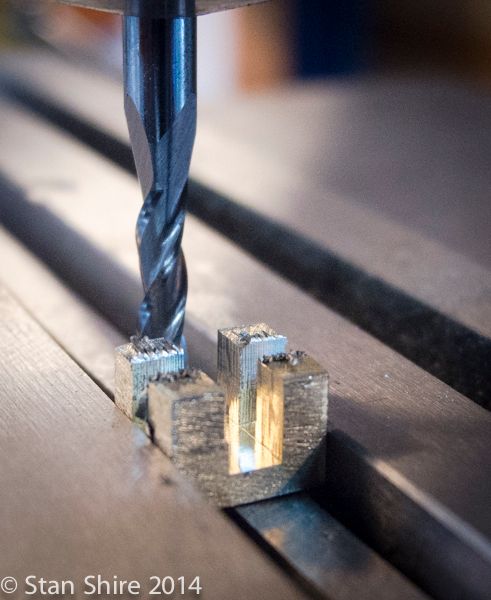

Now, on to the crosshead. I cut off a piece at the bandsaw and squared it up to size.

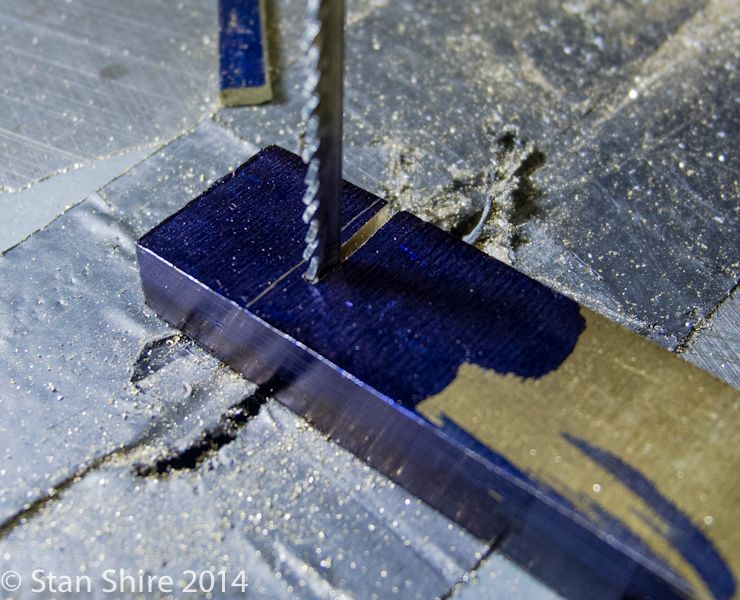

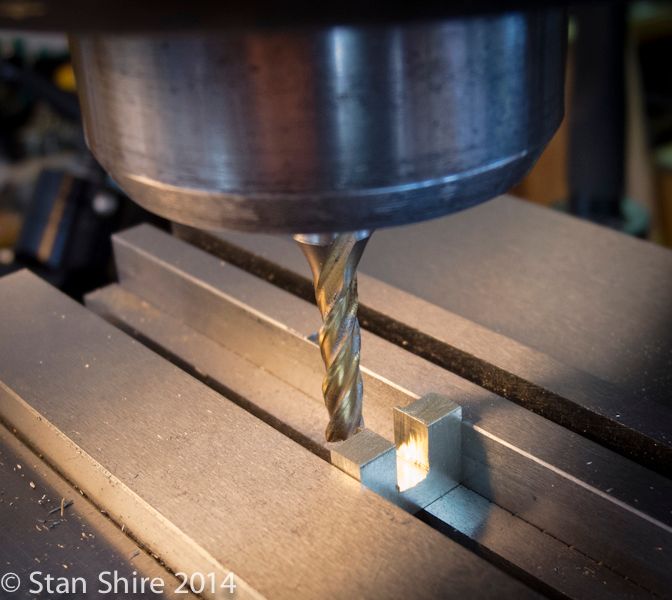

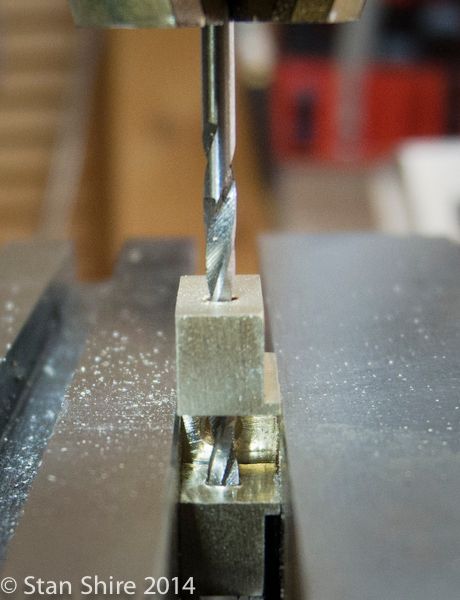

First, a guide boss was milled. This is the width of the crosshead guide spacing.

Then, one slot, one through hole and one cross hole.

The crosshead get checked off the parts list.

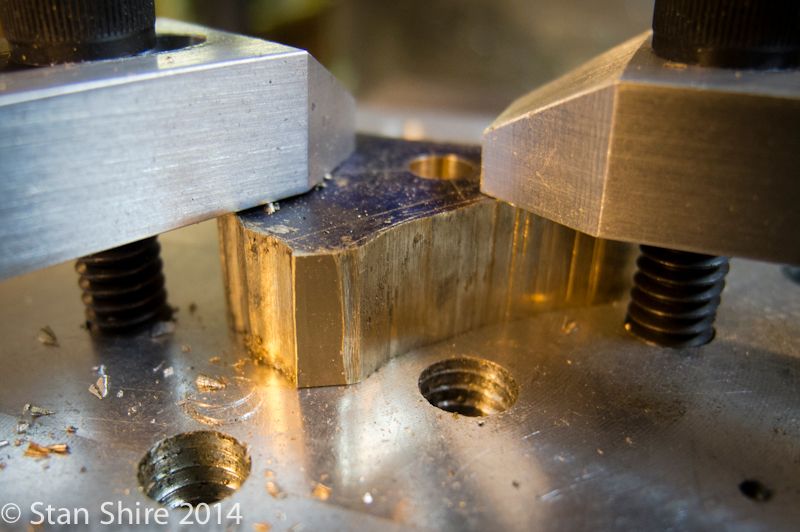

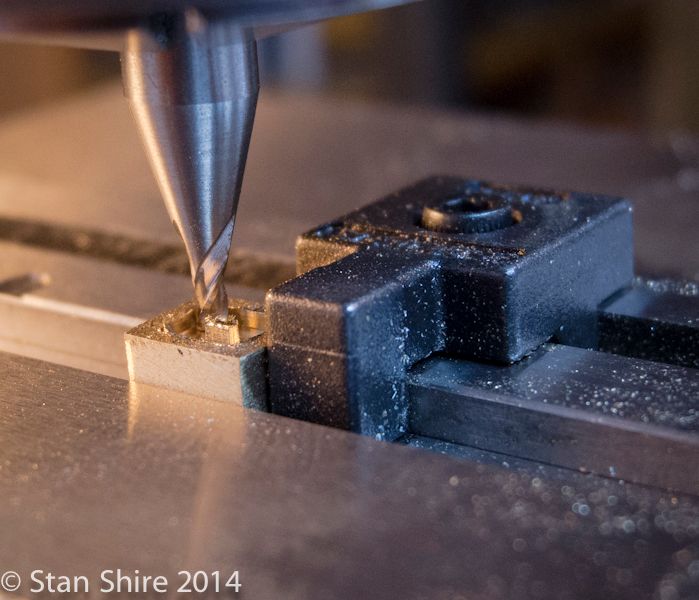

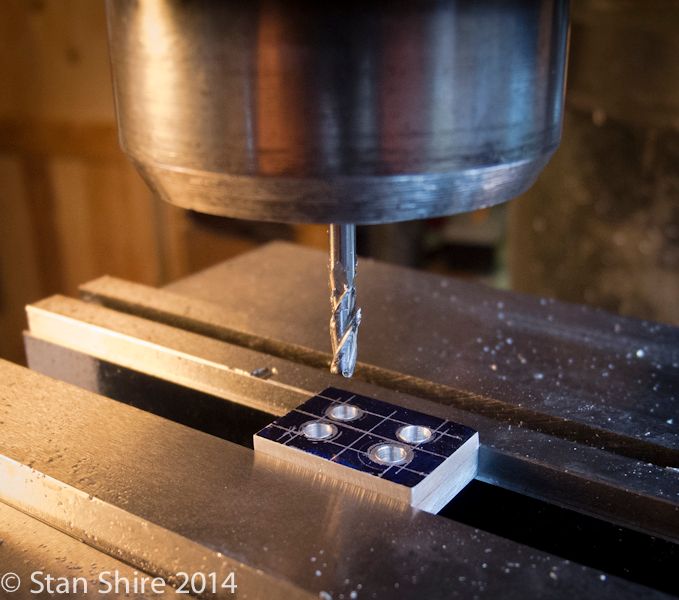

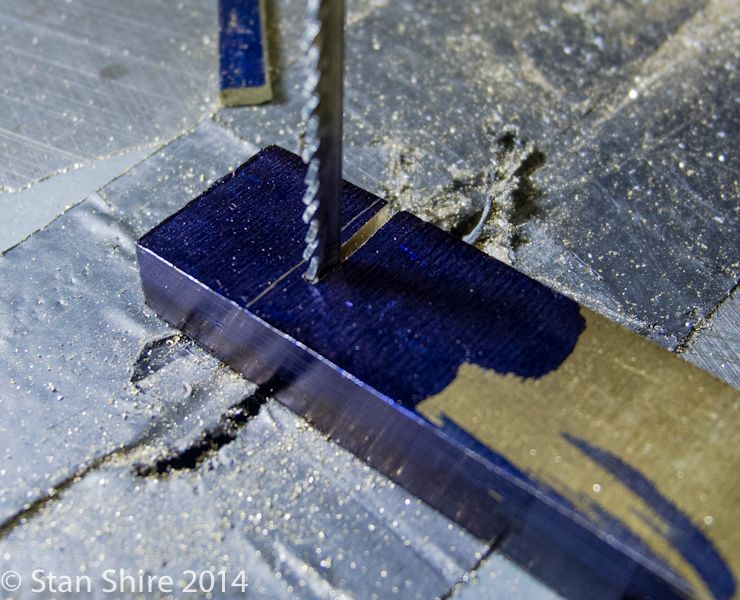

Talk about, fiddly bits and the valve has to be mentioned. Forget Finding Elmo. There is a valve in here somewhere.

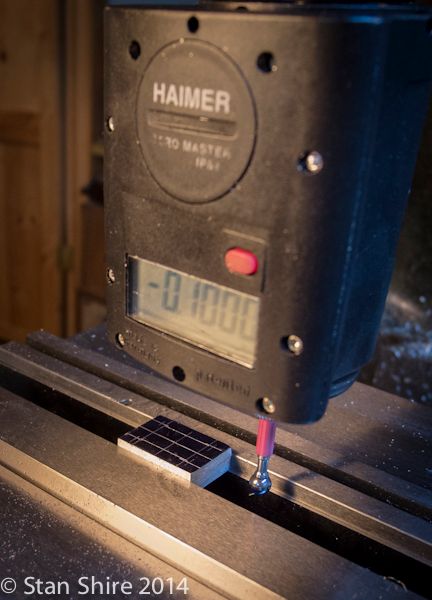

.0625 stubby end mill. The vise stop looks huge compared to the valve.

More tiny milling

The valve bottom. Check that part off.

Next is the end that threads onto the valve rod. Some turning and shaping at the lathe, then a slot and cross hole at the mill.

The valve rod Loctited and curing.

Not too many parts to make. A shoulder bolt, some pins, the pack nuts and the flywheel.

Stay tuned.