Hi folks

I know you are primarily discussing the aspects of touch point edge finders here, but I want to take the opportunity to show you another (definitely not new) approach to the theme finding edges on the milling machine.

I have, like many others of you, a variety of conventional mechanical edge finders in my shop for several years now

but since I made my own finders based on simple ball bearings the commercial ones are very seldom in use.

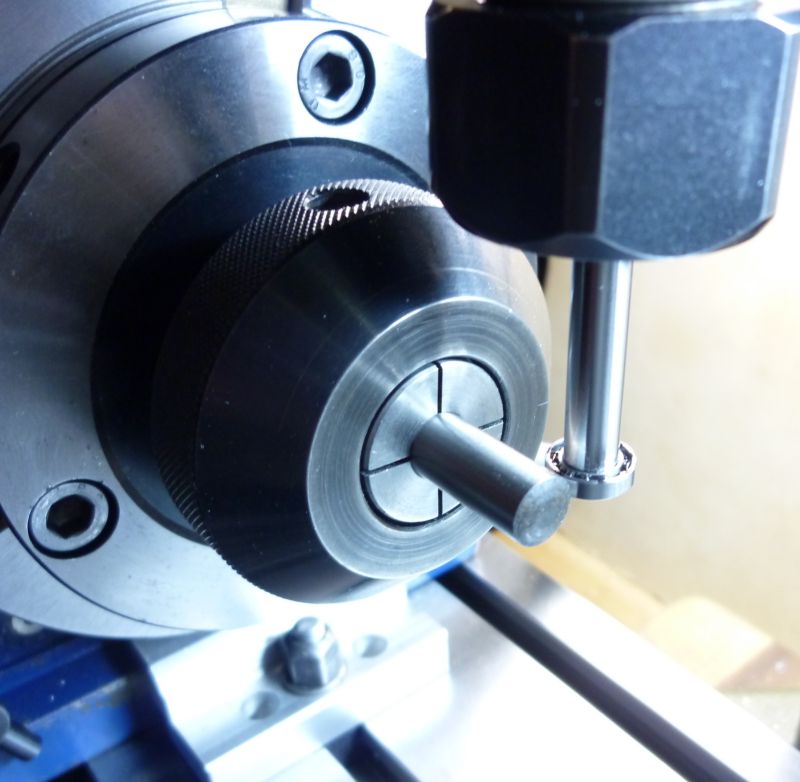

To make this type of edge finder you only need two things, a suitable ball bearing and a true running shaft. For the shafts I like to use ground dowel pins, they are straight enough for this job and have a precise diameter. Our German dowel pins with m6 fit have nearly no clearance to a ball bearing hole. So normally you get a slight press fit from only pushing them into the bearing and this will fix things strong enough. But needles to say you can use any sort of straight self turned shafts also and if you have problems with a precise press fit to the bearing a drop of Loctite might help a lot.

To me that sort of edge finders have several advantages:

They are cheap and easy to build, so you can make a whole assortment of that useful helpers for different shop tasks. Most of you will have all the needed components in your drawers anyway.

You can make several edge finders with different shaft diameters of your main collet sizes, so you dont have to change collets so often when using a variety of tooling on the mill.

Ball bearing finders work proper in a wide range of spindle speed, you can use them up to 4000 rpm and even more without any problem. This can be very useful on machines without variable speed control, no more drive belt altering when changing to the edge finder while you are on high speed milling operations.

And the edge detection is really precise and easy to read, to my experience +/- 0.01mm (0.004in) ore even better is always reproducible.

To get an impression how it works you can have a look at this little video, the mill is running with 3000 rpm at this time:

http://pl-hi.de/JST/Ball-Bearing-Edge-Finder-01.mpg

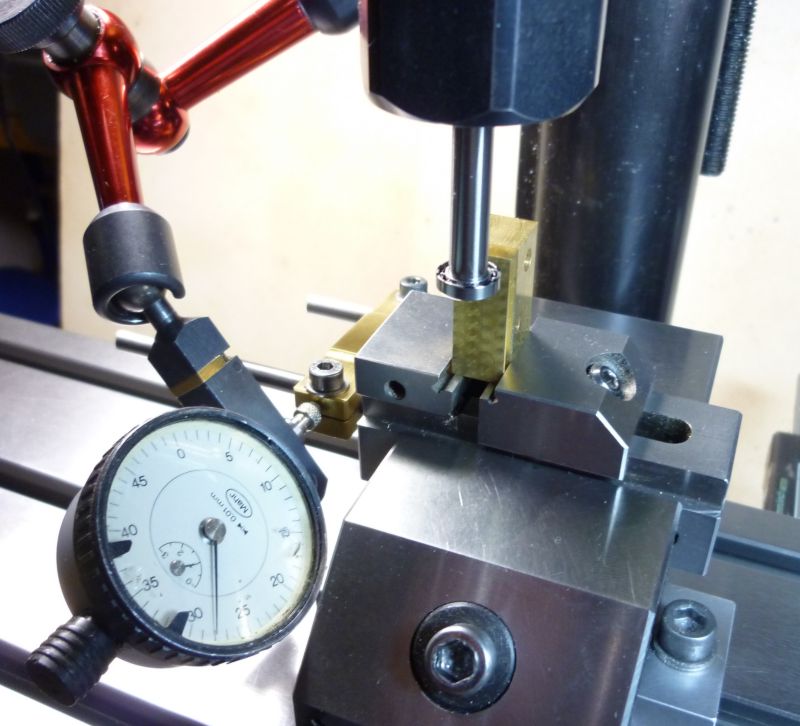

And here is the scenario for another video using a dial indicator

to demonstrate the reproducibility when getting in contact with the surface of your work piece. The counter has a graduation of 0.01mm.

http://pl-hi.de/JST/Ball-Bearing-Edge-Finder-03.mpg

Good Night

Achim