Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

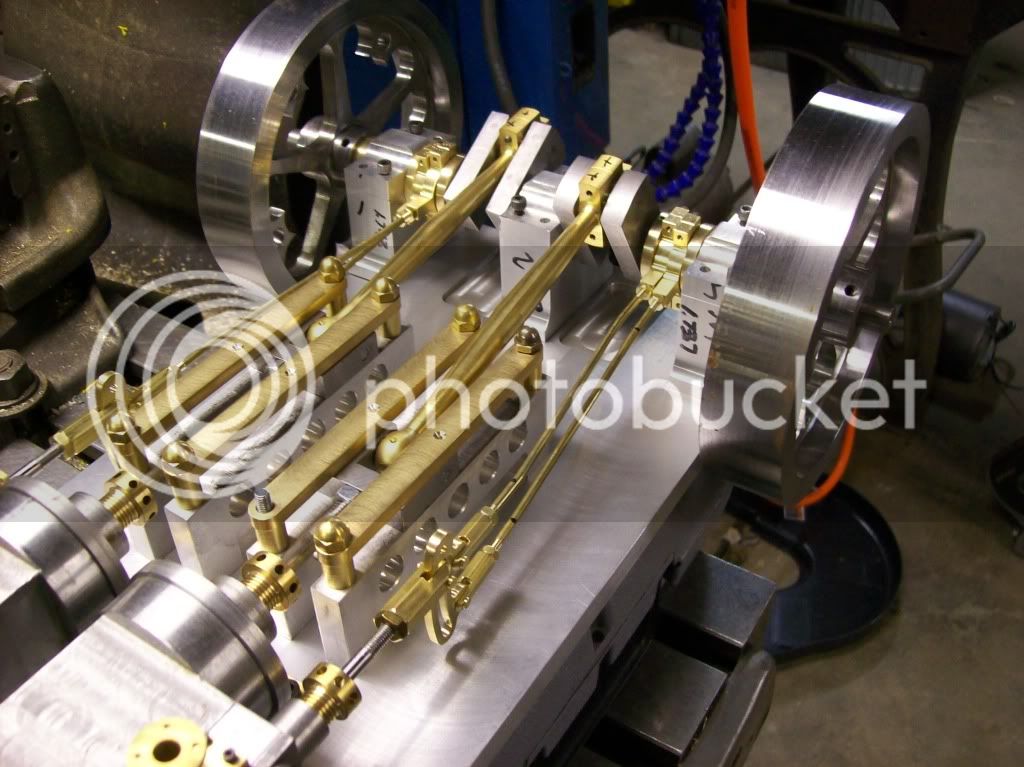

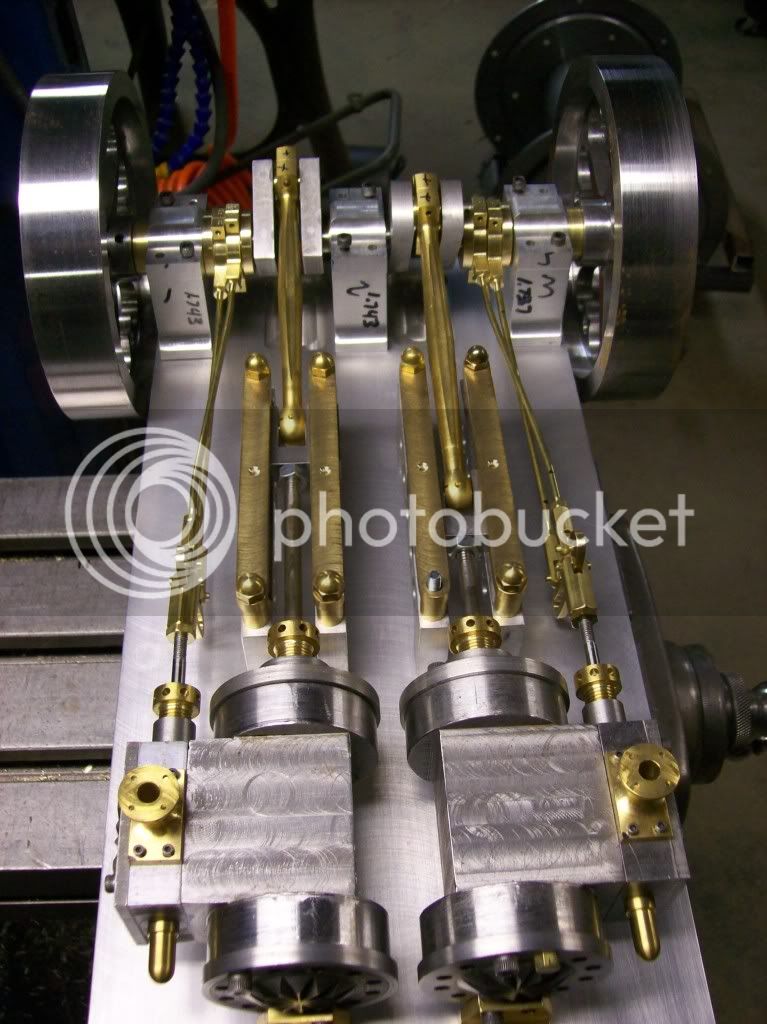

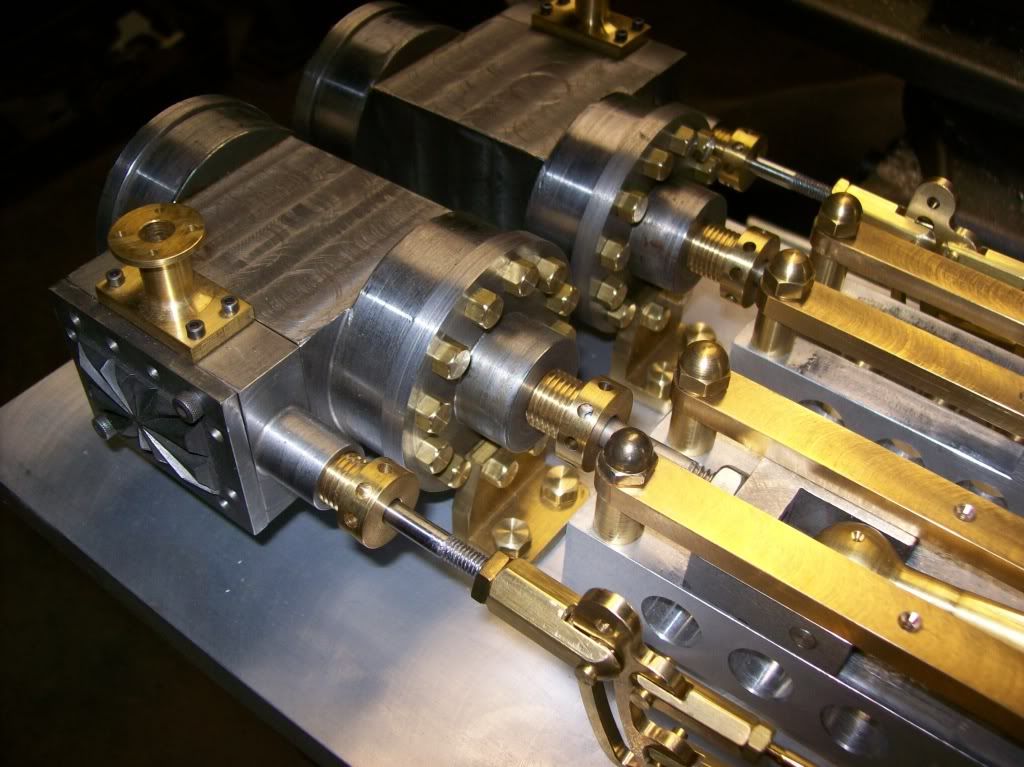

Nicely done Tom. I have a question. Typically I've seen two mating parts made from dissimilar metals to prevent galling. But the use of brass eccentrics and straps seems to be fairly common from what I've seen. Is that because the motion is pretty limited so galling isn't a problem?

Cheers,

Phil

Cheers,

Phil