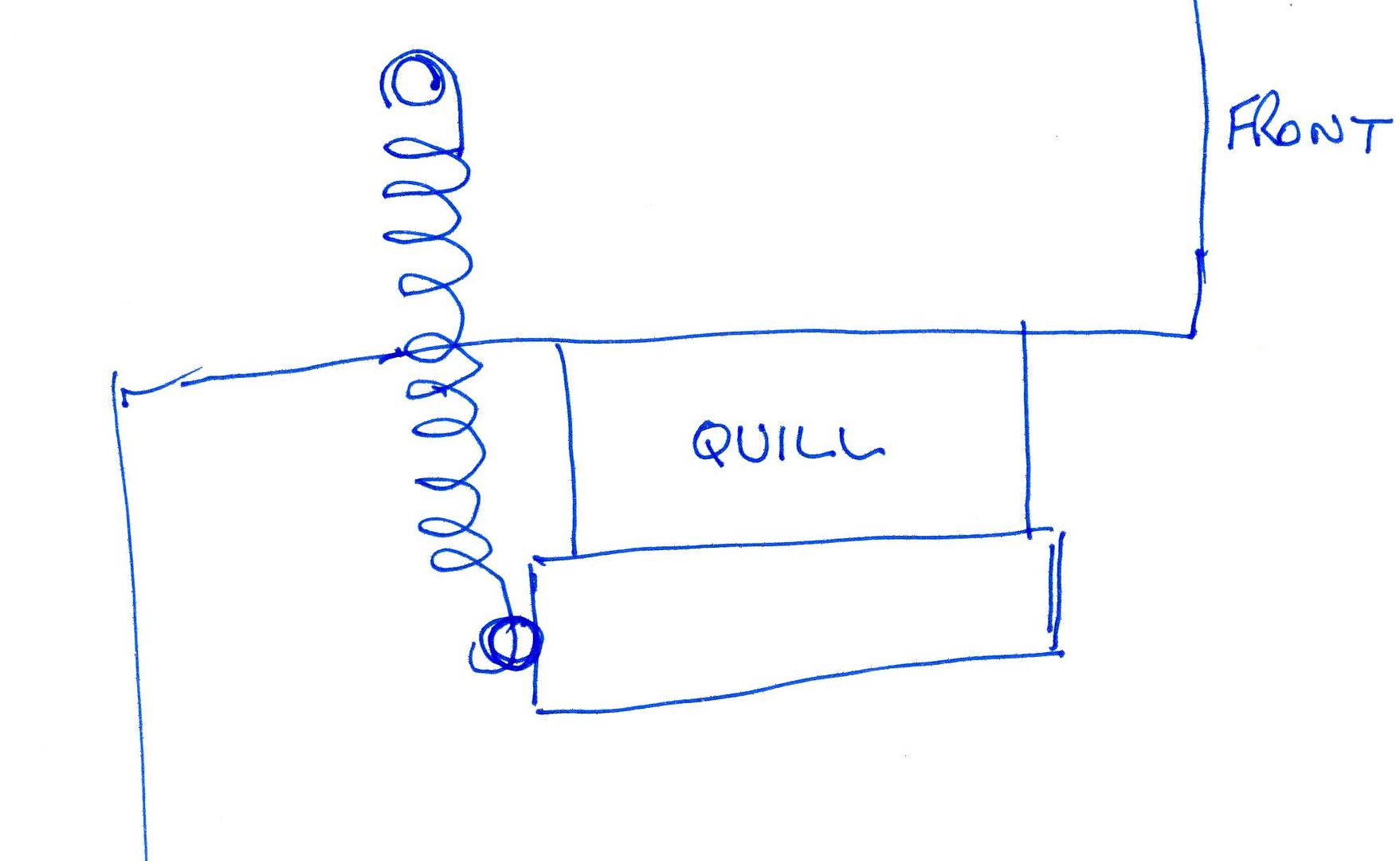

I have a HM45 which I suspect is a little smaller than yours but probably a similar design. On mine, the quill has a rack cut into it directly and the down feed (or fine feed) uses a gear meshed with the rack to lower/raise the quill. In this setup there is a lot of backlash (up to 2mm). When the quill is being lowered it's weight allows it to drop but it sits on the 'bottom' of the rack teeth. When it encounters resistance, like a plunge cut or drilling, it is free to move (or bounce) up because of the backlash in the rack. If I keep driving the cutter down I eventually overcome the backlash and can control the cutter again. The bigger problem doing it this way though, once I hit my depth and stop feeding the quill, it can still descend the amount of the backlash and go too deep.

Long story I know, but this might be your issue. If it is, I've heard it can be fixed by adding some sort of resistance (spring, shock absorber, etc) which holds the quill up against the top of the rack teeth and eliminates the backlash problem. One day I'll mod mine.

Edit to add: To test if this might be your issue, lower the quill some, then grab hold of it and see if you can lift it up at all. Even if it only moves a little it could be the cause. Another way would be to start drilling and feed aggressively and see if the chatter goes away as you force the drill deeper (using up all the backlash).