chucketn

Senior Citizen

Stan,

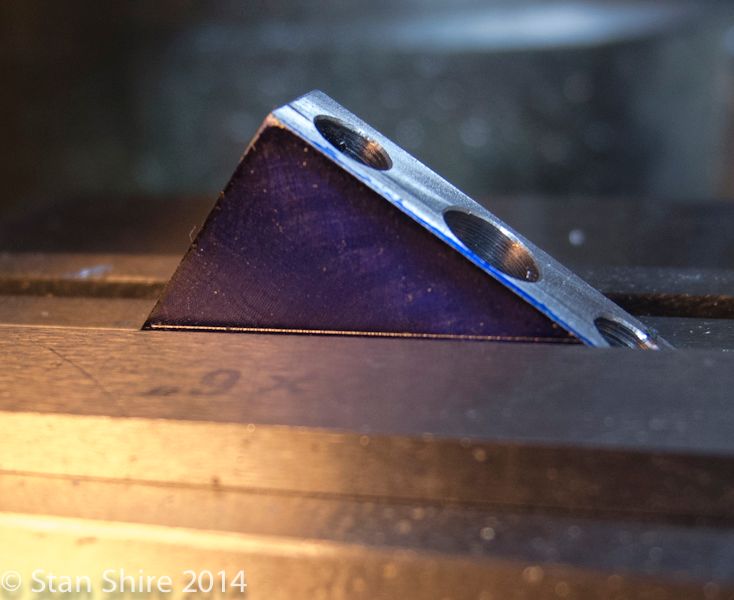

More info on the 'Angle Fixture', please? Is it home made or store bought?

Nice work!

Chuck

More info on the 'Angle Fixture', please? Is it home made or store bought?

Nice work!

Chuck

Hey Chris

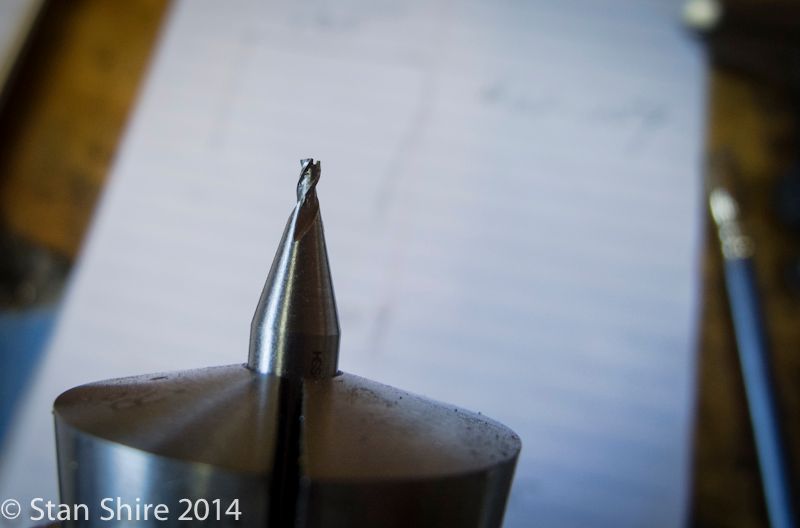

Thanks. I got that angle block not knowing if it would be useful. Turns out I've used it a whole lot.

How's the Bridgeport

The Bridgeport has been great...I've been fighting rust ever since I got it though. Every time I turn my heater on the machine starts "sweating" and before long rust. I hit it the areas with a scotch-brite pad and then apply white grease but it's getting old.

I'm be watching your Elmers build...good stuff!

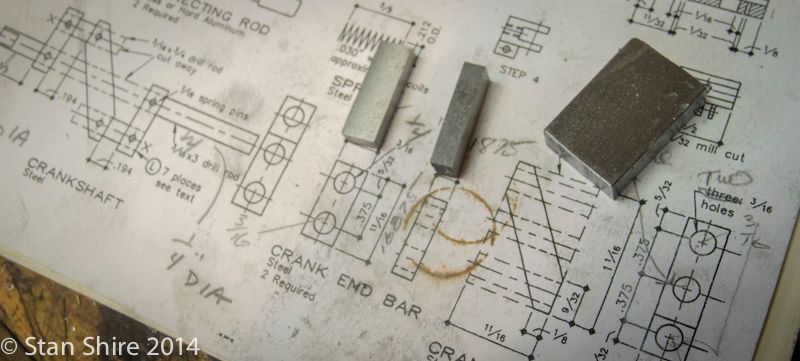

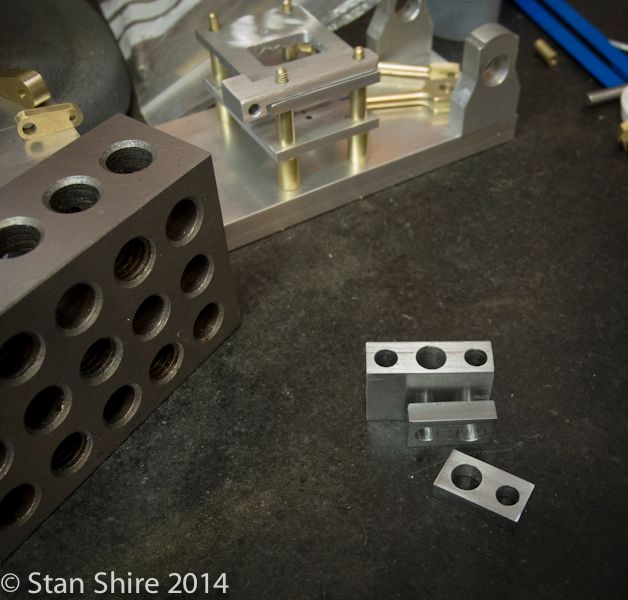

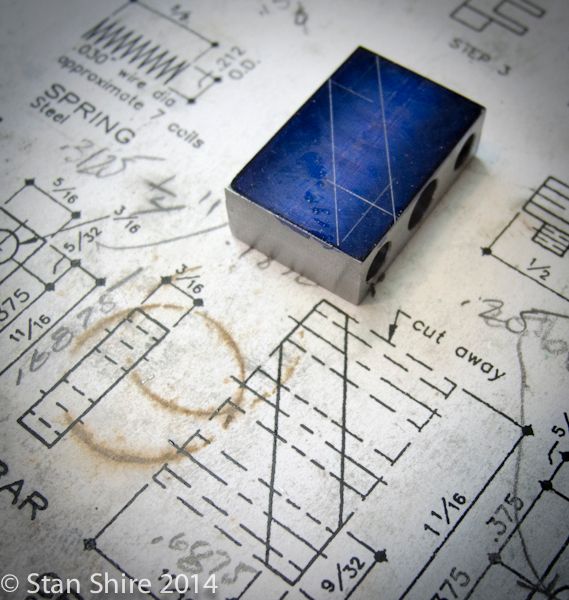

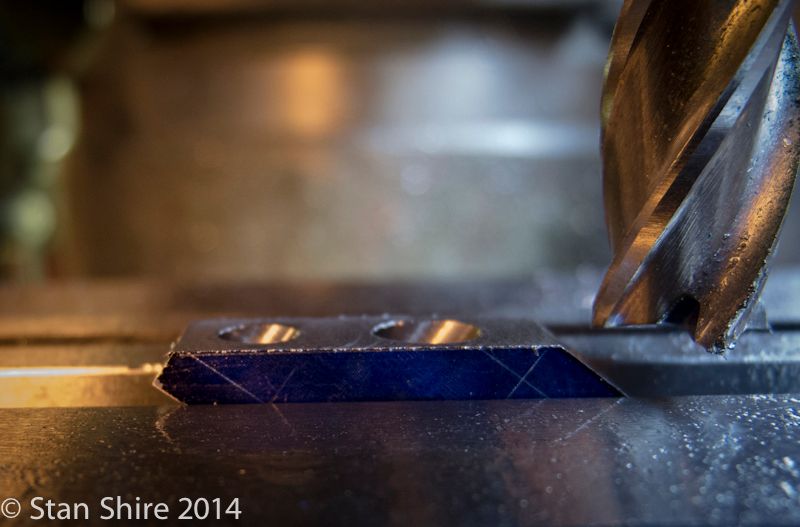

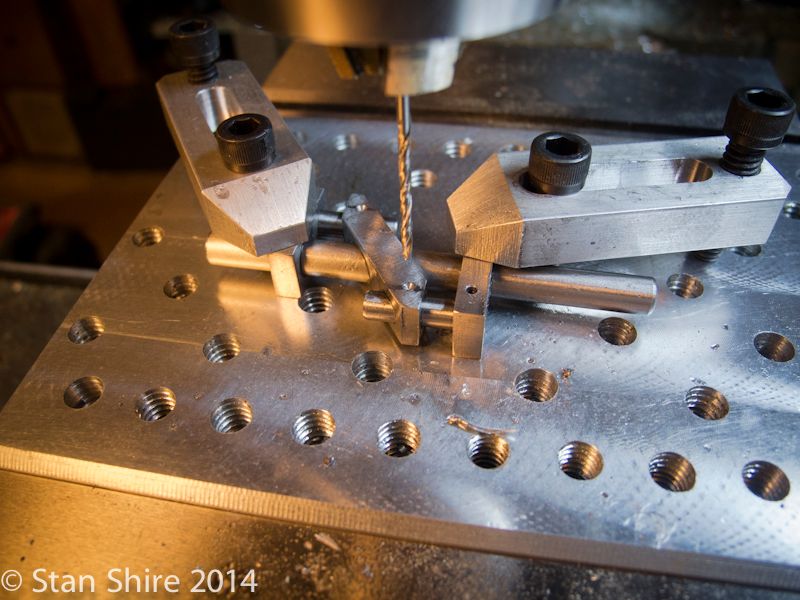

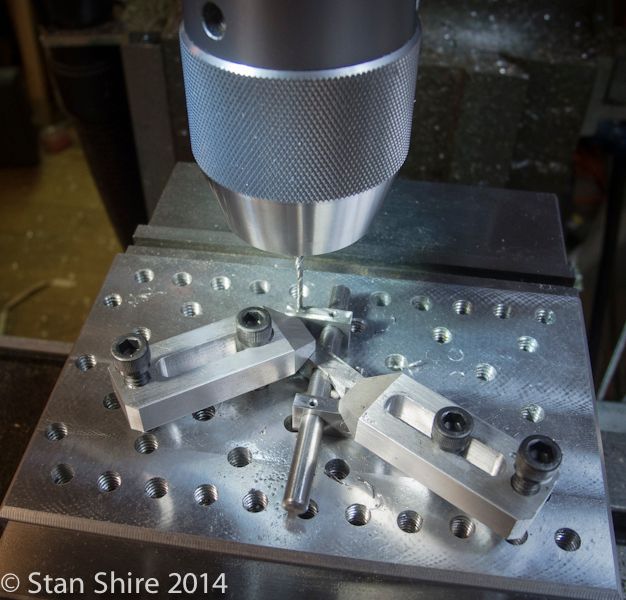

I probably spent more time making the offset fixtures

Phil

No more crazy than remaking a part until I'm happy with it. Sometimes more than twice. On the Liney RV-2 build, I was almost finished but the 4 cylinders were bothering me. The "cooling fins" weren't spaced precisely. If you looked carefully, each cylinder was slightly different. Turns out the Y axis DRO scale mount had loosened enough to screw with the readings. So, I now have a spare set of cylinders.

Good thing this isn't my real job. But, since I'm the boss, shop manager, QC dept, CEO, floor sweeper, etc., doesn't matter how many parts are scrap or rejected.

I keep a container for NO-GO parts to remind me to pay attention.

BTW, where are u in South Easterm PA? I grew up 30 miles south of PGH.

Enter your email address to join: