- Joined

- Mar 26, 2010

- Messages

- 38

- Reaction score

- 1

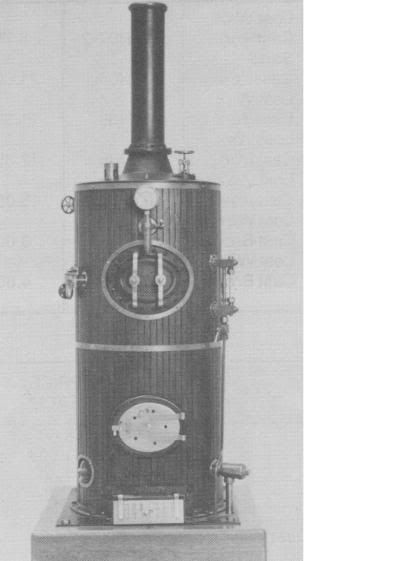

I'm doing a redraw of plans for a boiler for my Donkey engine. I had drawn a set 3 years ago based on the boiler in the William Harris book but basically doubling the size and building it from steel. I went by the ASME code which was no problem except for the size of the cleanout fittings. I had the calculations and design checked by a friend who is a Mechanical Engineer and He said it was OK. One of the beauties of 3D Cad is the ability to see a rendered view of your drawing and because of the fitting sizes it looked nasty so The plan is to redraw it based on the Australian Miniature Boiler Code with a few other changes. Due to the difficulty of getting approval nowadays the boiler may never be built but at least I'll have drawings I like. So, I have some questions that someone might help me with.

My experience is with loco or traction engine boilers where all surfaces of the pressure vessel that are exposed to the products of combustion must be protected by water to prevent burning of the steel. In a vertical boiler what protects the upper part of the firetubes and is there a formula or recomendation for tube lengths? Thanks John

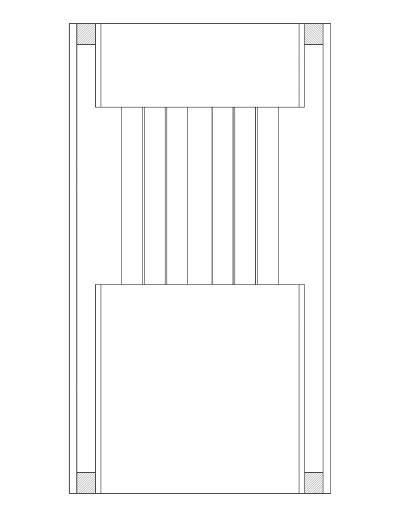

The proposed boiler barrel is 10" schedule 40 pipe, and the firebox will be either 6" or 8" schedule 40 pipe. The firebox access tube is 3" schedule 80 pipe. The boiler would be 22" high with 17 - 3/4" tubes. it would measure about 14" between the tube sheets

My experience is with loco or traction engine boilers where all surfaces of the pressure vessel that are exposed to the products of combustion must be protected by water to prevent burning of the steel. In a vertical boiler what protects the upper part of the firetubes and is there a formula or recomendation for tube lengths? Thanks John

The proposed boiler barrel is 10" schedule 40 pipe, and the firebox will be either 6" or 8" schedule 40 pipe. The firebox access tube is 3" schedule 80 pipe. The boiler would be 22" high with 17 - 3/4" tubes. it would measure about 14" between the tube sheets