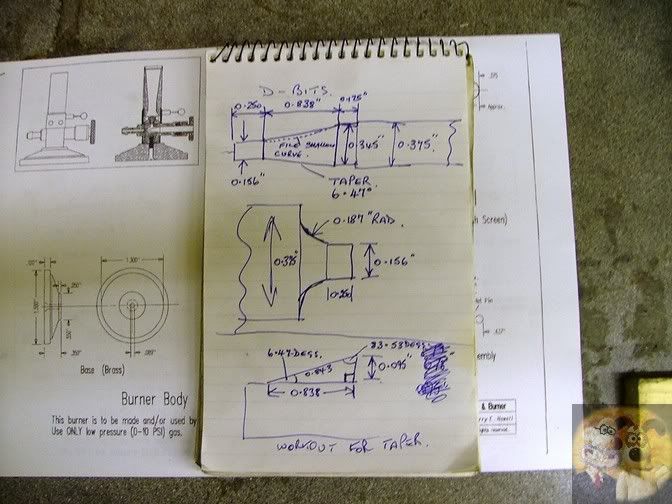

I couldn't find my article on making a D-bit, so I have made up one from my photo archive.

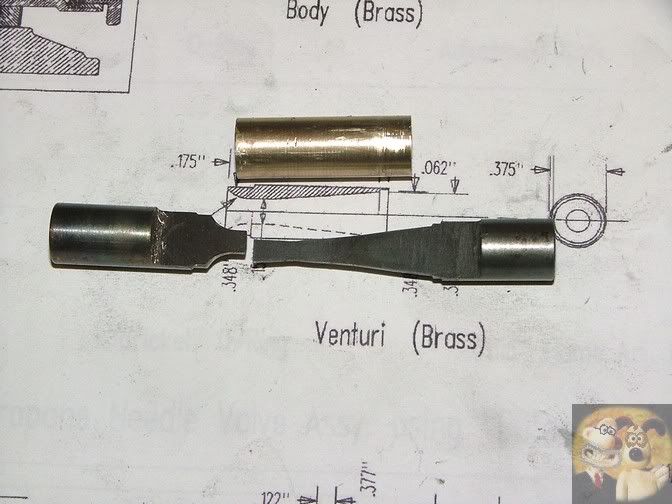

First off I worked out from the drawing what was required to get the correct shapes at either end of the venturi. Part on the upper left next to the notepad.

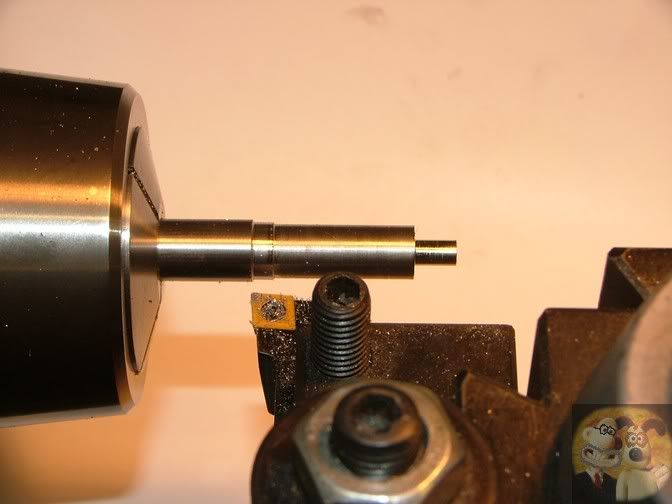

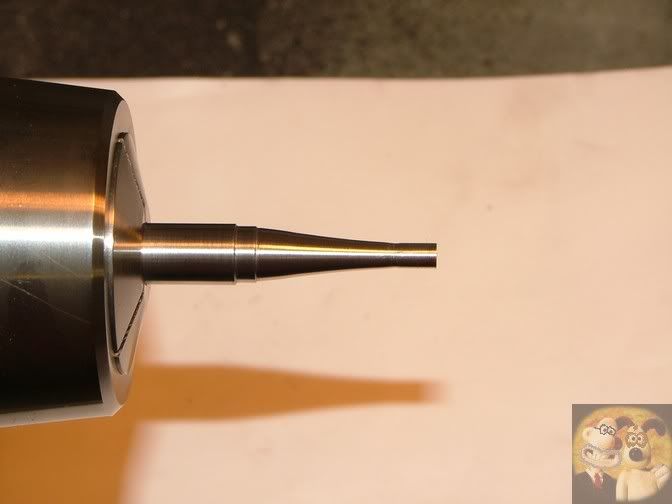

A piece of the correct diameter silver steel mounted into chuck.

The front and rear profile turned up either end of where the taper will be.

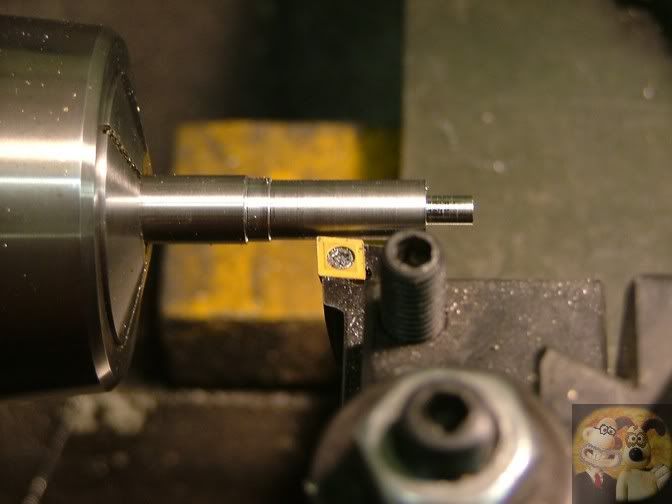

Topslide set over to the correct angle.

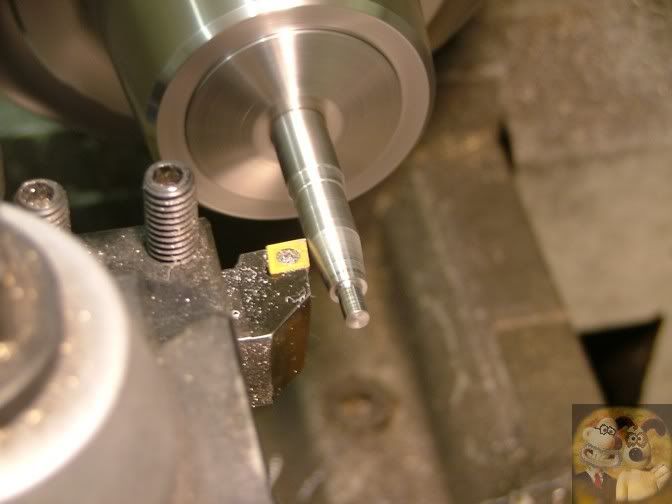

Starting to cut the angle between the two end diameters.

Finished angle after filing on a slight curve and polishing with emery and wire wool.

Now transfered onto the mill to start the cutting down to halfway + 1 or 2 thou. Notice that I am cutting into the original size of silver steel, this is where I am going to take my measurements from.

Measuring up, half the original diameter plus a bit.

Notice that I haven't removed the burrs, if you do that, you are liable to round over the cutting edges and the D-bit won't cut. Disregard the mic readings as these were just set up to show where to measure it.

Heat up the bit and hold it there for at least a couple of minutes, then quench. It should end up rock hard.

Now onto an oil stone or W&D paper and gently flat down the cut face. You should be able to remove very little material and still retain a thou or two oversize. This should enable you to resharpen a few times if it goes a little dull without going below the half measurement.

The two cutters made to allow me to make the venturi.

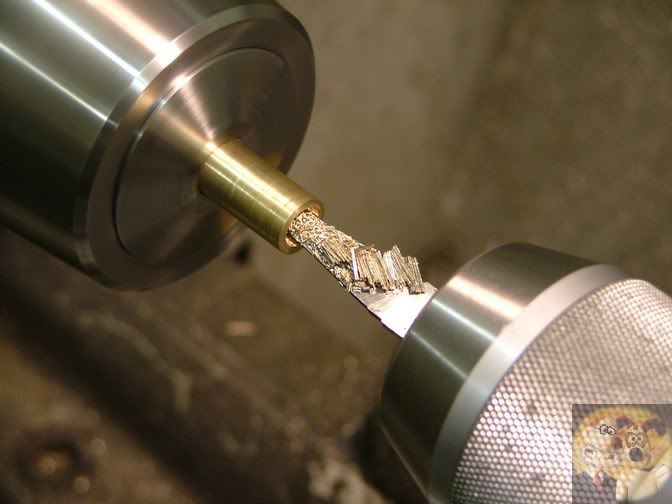

Cutter in action. Because it can't get it's own swarf away, you peck at the job, cleaning off the swarf as you go deeper. See how nicely it shaves the material out if you have made the D-bit correctly. If it doesn't cut this well, there is something wrong.

Unlike this one, which I completed then found that my supplier had slipped a bit of the wrong stuff into my silver steel order. It cut on the lathe like the right material, but it wouldn't harden,

D-bits are a method of getting precision holes bored without resorting to special sized or specially ground reamers. At times they can be the only way out of a sticky situation.

I forgot to mention, these two bits followed a previously drilled hole so didn't need to cut on the very front tip. If that is needed, then the front edge needs to have a cutting rake ground onto the very tip of about 5 degrees.

I hope this helps

John