mklotz

Well-Known Member

Probably one of the most frustrating tools in the hobbyist's arsenal is the cordless electric drill. It's undeniably handy but, if you're like me, dealing with the batteries is enough to make you wish that Maxwell and Faraday had just kept their discoveries to themselves.

I wanted to drill a single hole out on the patio. Not wishing to deal with stringing an extension cord through a window, etc., I reached for the Craftsman 12V drill my daughter gave me a few years ago. No the battery wasn't dead - it managed to revolve the chuck at a stately 33-1/3 rpm for about ten seconds. Then it was dead. The backup battery that came with the drill hasn't been able to hold a charge since its second recharge. I reached for the backup cheapy drill from HF and it could spin its chuck but only if I didn't hold on to it. I hadn't used it in about a month so, of course, the battery had run down.

After exhausting my repertoire of curse words in three languages I started thinking about the problem. The real advantage (at least to me, an occasional user) is not that they're cordless but that one doesn't have to string (110 VAC) extension cords to use them. (Sounds confusing but stick with me.) I wouldn't mind if the thing had a short cord attached to a battery if that battery was more dependable than the ones supplied with these drills.

The typical NiCd supplied has all sorts of "memory" problems that can interfere with it taking and holding a decent charge. The manufacturers don't supply charging instructions and the chargers they supply have no "smarts".

But 12V Sealed Lead Acid (SLA) are widely available in small size packages, have decent capacity, and can hold a charge.

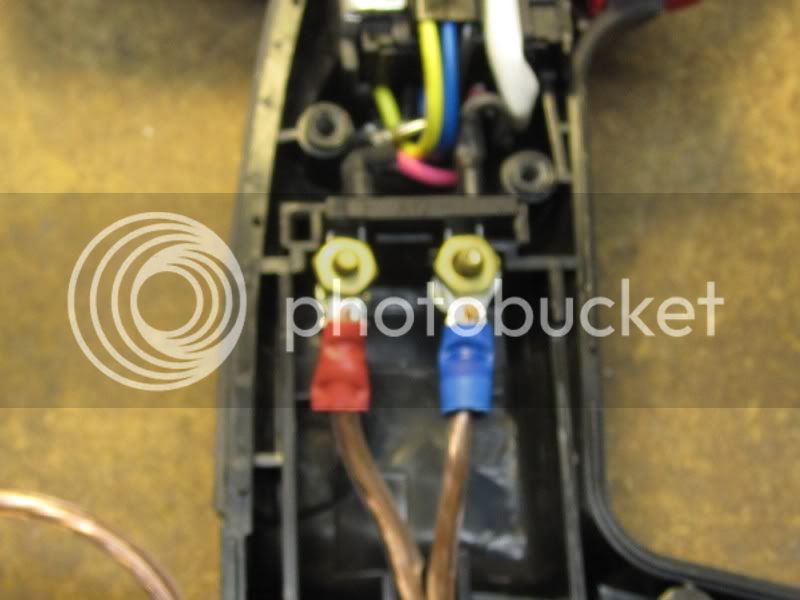

So, I opened up the drill and found the battery contacts...

Attached a hunk of speaker cable with some brass screws...

and, voila, a corded cordless drill...

Now the thing spins like a banshee and has torque to spare. The drill draws about 1.5 A at top speed and the battery is a 5 A-hr so it should last for at least an hour or two of use. I've never done anything with a cordless that took longer than a few minutes of drill run time so I think I'm in good shape there.

Lead-acid technology is well understood and smart chargers are widely available and inexpensive. Mine delivers 0.75A so it should be able to recharge the battery in 6+ hours. I intend to leave it on trickle charge most of the time so it's always ready to go.

I wanted to drill a single hole out on the patio. Not wishing to deal with stringing an extension cord through a window, etc., I reached for the Craftsman 12V drill my daughter gave me a few years ago. No the battery wasn't dead - it managed to revolve the chuck at a stately 33-1/3 rpm for about ten seconds. Then it was dead. The backup battery that came with the drill hasn't been able to hold a charge since its second recharge. I reached for the backup cheapy drill from HF and it could spin its chuck but only if I didn't hold on to it. I hadn't used it in about a month so, of course, the battery had run down.

After exhausting my repertoire of curse words in three languages I started thinking about the problem. The real advantage (at least to me, an occasional user) is not that they're cordless but that one doesn't have to string (110 VAC) extension cords to use them. (Sounds confusing but stick with me.) I wouldn't mind if the thing had a short cord attached to a battery if that battery was more dependable than the ones supplied with these drills.

The typical NiCd supplied has all sorts of "memory" problems that can interfere with it taking and holding a decent charge. The manufacturers don't supply charging instructions and the chargers they supply have no "smarts".

But 12V Sealed Lead Acid (SLA) are widely available in small size packages, have decent capacity, and can hold a charge.

So, I opened up the drill and found the battery contacts...

Attached a hunk of speaker cable with some brass screws...

and, voila, a corded cordless drill...

Now the thing spins like a banshee and has torque to spare. The drill draws about 1.5 A at top speed and the battery is a 5 A-hr so it should last for at least an hour or two of use. I've never done anything with a cordless that took longer than a few minutes of drill run time so I think I'm in good shape there.

Lead-acid technology is well understood and smart chargers are widely available and inexpensive. Mine delivers 0.75A so it should be able to recharge the battery in 6+ hours. I intend to leave it on trickle charge most of the time so it's always ready to go.