I have committed to building a henry ford plumbing parts engine. I am baffled as to the size of the combustion chamber. I know what I like is about 6 to one ratio. I am thinking that the pounds per square inch would work out to atmospheric pressure X 6.

am I correct in assuming that I would have about 85-90 lbs pressure at the spark plug hole?

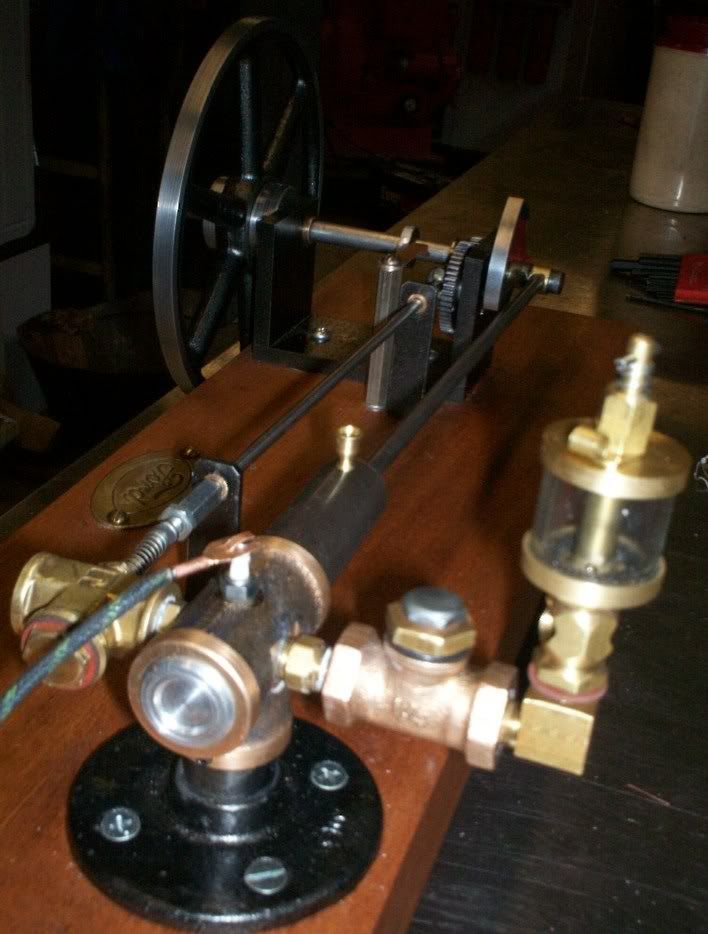

This afternoon I bored out a 3/4 black iron pipe nipple to a few thousands under 7/8. I intend to have a stroke of around 1 1/2". I will be using instead of a T, a 4 sided fitting with a spark plug in the top opening. I am going to use some well aged 1 1/2" thick maple instead of iron to support crankshaft and cam shaft. the maple is as hard to mill as 6061 and thin pieces can not be bent easily. I would appreciate any comments, thanks john

am I correct in assuming that I would have about 85-90 lbs pressure at the spark plug hole?

This afternoon I bored out a 3/4 black iron pipe nipple to a few thousands under 7/8. I intend to have a stroke of around 1 1/2". I will be using instead of a T, a 4 sided fitting with a spark plug in the top opening. I am going to use some well aged 1 1/2" thick maple instead of iron to support crankshaft and cam shaft. the maple is as hard to mill as 6061 and thin pieces can not be bent easily. I would appreciate any comments, thanks john