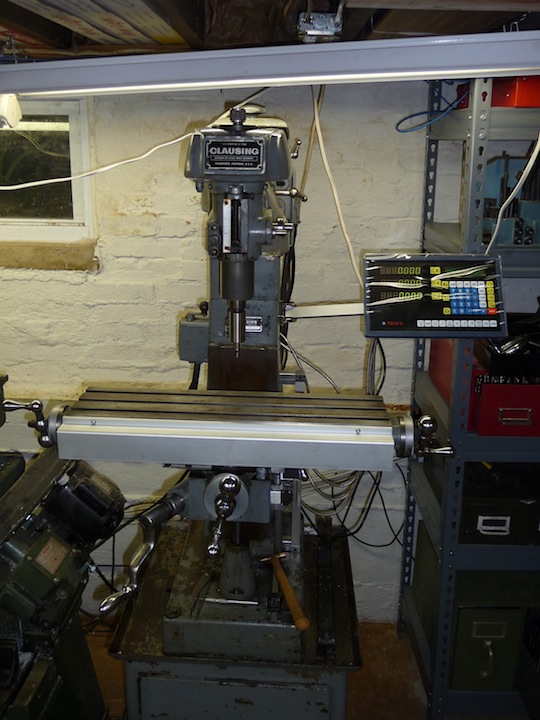

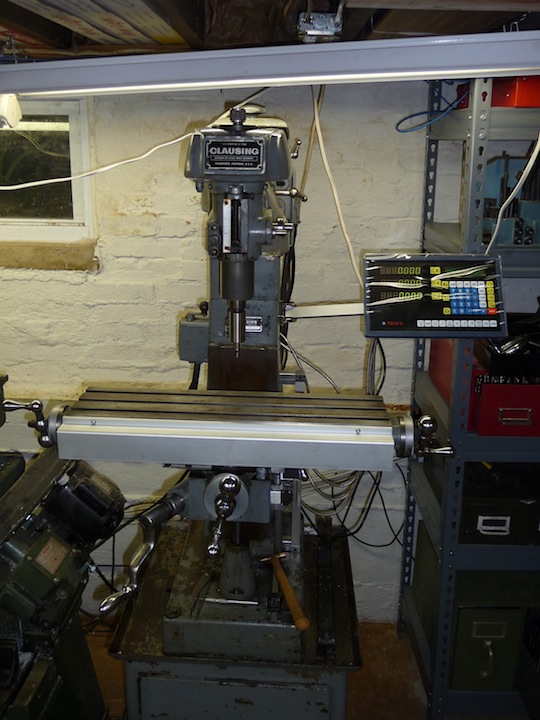

I read your write up, Dale. You did a really nice job and it reminded me of my own DRO installation adventures. Sometimes, it's hard to determine just how to mount scales, especially when the machine castings are curved.

The hardest was the DRO for my Hardinge lathe. The Hardinge is 99% curved, almost art deco in shape, and to get the lathe Z-axis correct, especially, was a challenge.

You'll love working with your DRO. No more backlash, no more dials.

You'll find that with a DRO, you'll change how you do work. For example, you rarely need to lay out or center pop anything. The DRO will be far more accurate than scribes and rulers. You'll also probably find that you'll use the CENTER of an object as the origin, rather than one corner. Doing this produced nice symmetry. For example, you've got a rectangle and you need to drill 4 holes in it spaced proportionally, you can measure the stock before it goes in the mill, pick up the edges with an edge finder, then run the table to the exact center and set X and Y to 0,0. Now your four holes become plus and minus values across two imaginary central lines, like X plus and minus 2.000", Y plus and minus 1.000", and the end result is perfect.

Bolt circles, too. You can drill and tap two separate pieces, specifying a 6-count 4.000" bolt circle, and the holes will line up perfectly.

You'll love it. I'll never work on another mill or lathe without DRO again.