Hi to all!

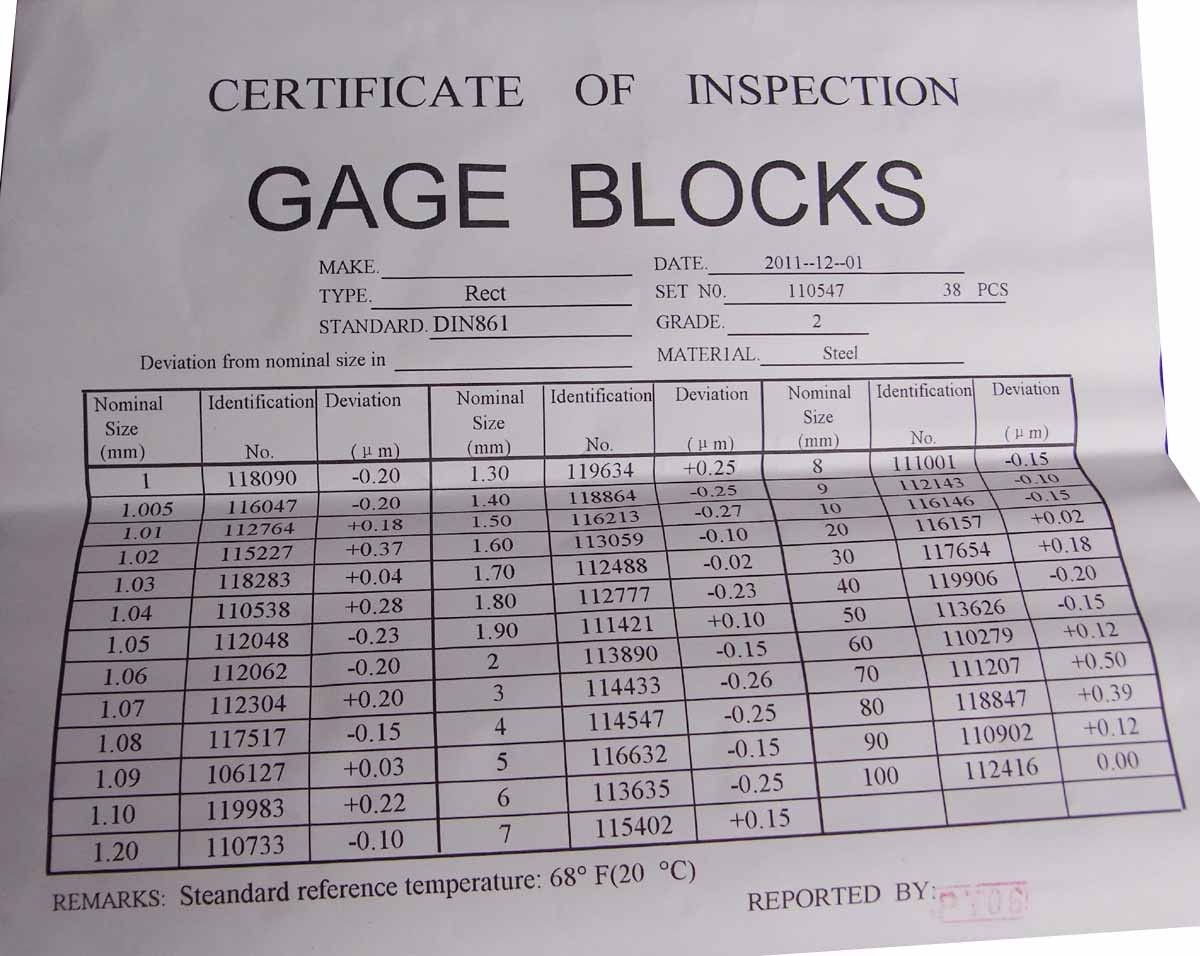

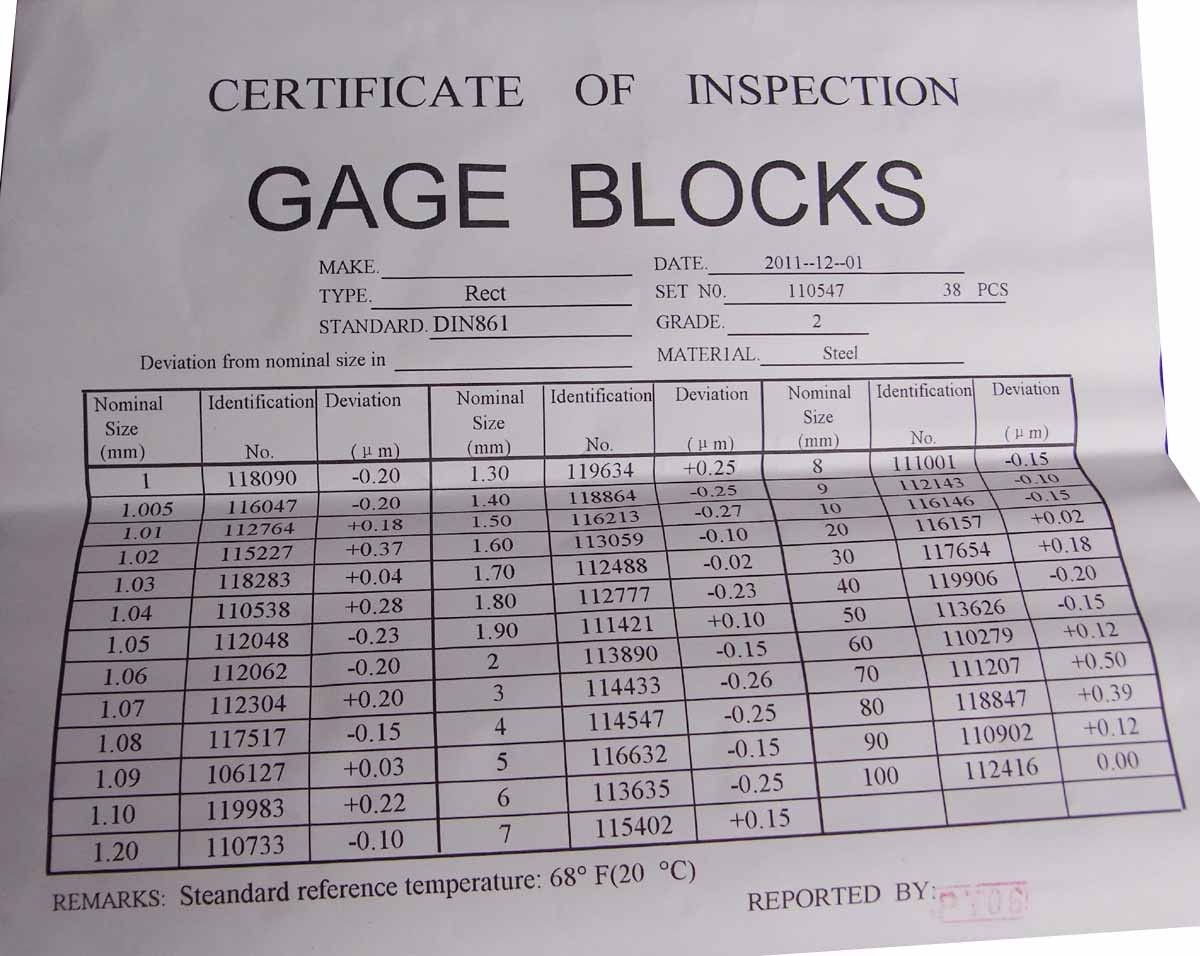

I would like to get a set of gage blocks to make calibrations on my tools and measuring practice, I would like to buy some good brand but they are far out of my reach, then I looked this import set on ebay around US$100 with shipping to my country.

The cuestion is, is this set worth it?? or better save my money and buy some recognized brand loose blocks (for this price maybe only two)

I will apreciate very much any input! Thanks

Saludos

I would like to get a set of gage blocks to make calibrations on my tools and measuring practice, I would like to buy some good brand but they are far out of my reach, then I looked this import set on ebay around US$100 with shipping to my country.

The cuestion is, is this set worth it?? or better save my money and buy some recognized brand loose blocks (for this price maybe only two)

I will apreciate very much any input! Thanks

Saludos