BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

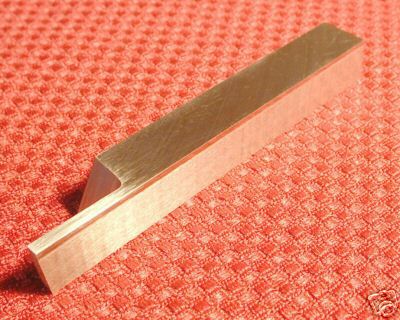

I'm basically lazy in the shop ( ;D), so I wanted to pass along these little parting-off tools I discovered on eBay:

I say lazy because you could easily make one for yourself, but why bother? This guy ( eBay seller "samsws" ) will sell you one for about 10 bucks. I bought 3 and really liked them. Still using the first one in fact.

They're basically pre-ground part-off tools made of tool steel. I also love my Aloris insert cutoff tool, but this one makes a narrower cut. Seems like it would also be handy for grooving. And, it fits in a regular QCTP holder. These little guys cost $9.50 for a single tool in 3/8 shank.

Mine has lasted a long time now, so I have no idea what their life really is. I touch it up with a stone every now and again. Search for "parting mini lathe" on eBay to find them too.

I'm no relation to the guy, I just like his parting-off tools.

Cheers,

BW

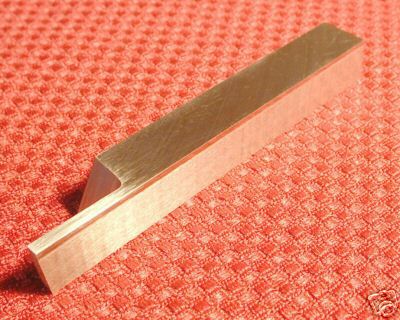

I say lazy because you could easily make one for yourself, but why bother? This guy ( eBay seller "samsws" ) will sell you one for about 10 bucks. I bought 3 and really liked them. Still using the first one in fact.

They're basically pre-ground part-off tools made of tool steel. I also love my Aloris insert cutoff tool, but this one makes a narrower cut. Seems like it would also be handy for grooving. And, it fits in a regular QCTP holder. These little guys cost $9.50 for a single tool in 3/8 shank.

Mine has lasted a long time now, so I have no idea what their life really is. I touch it up with a stone every now and again. Search for "parting mini lathe" on eBay to find them too.

I'm no relation to the guy, I just like his parting-off tools.

Cheers,

BW