- Joined

- Jul 16, 2007

- Messages

- 2,987

- Reaction score

- 1,056

The topic of carburetion has come up on several threads, one on Steve's straight eight engine and another one that Chuck started.

This is going to be an open discussion on carb operation and design. Everyone who has built an IC engine has used a carb, whether of their own design, a copy of another or a store bought unit.

I have been fooling with them for quite awhile and have built several different types.

When I first built my 302 engine I made up a rather sophisticated carb, by that I mean it had a float, an idle circuit, a high speed circuit and a blade type throttle plate. The first problem was getting the float to seal. The float itself was made from .002 brass shim stock and soldered together. The problem was that the float didn't have enough displacement so it didn't apply much pressure on the needle valve. I eventually eliminated it and went to a gravity feed to the carb. It worked ok but not to my liking.

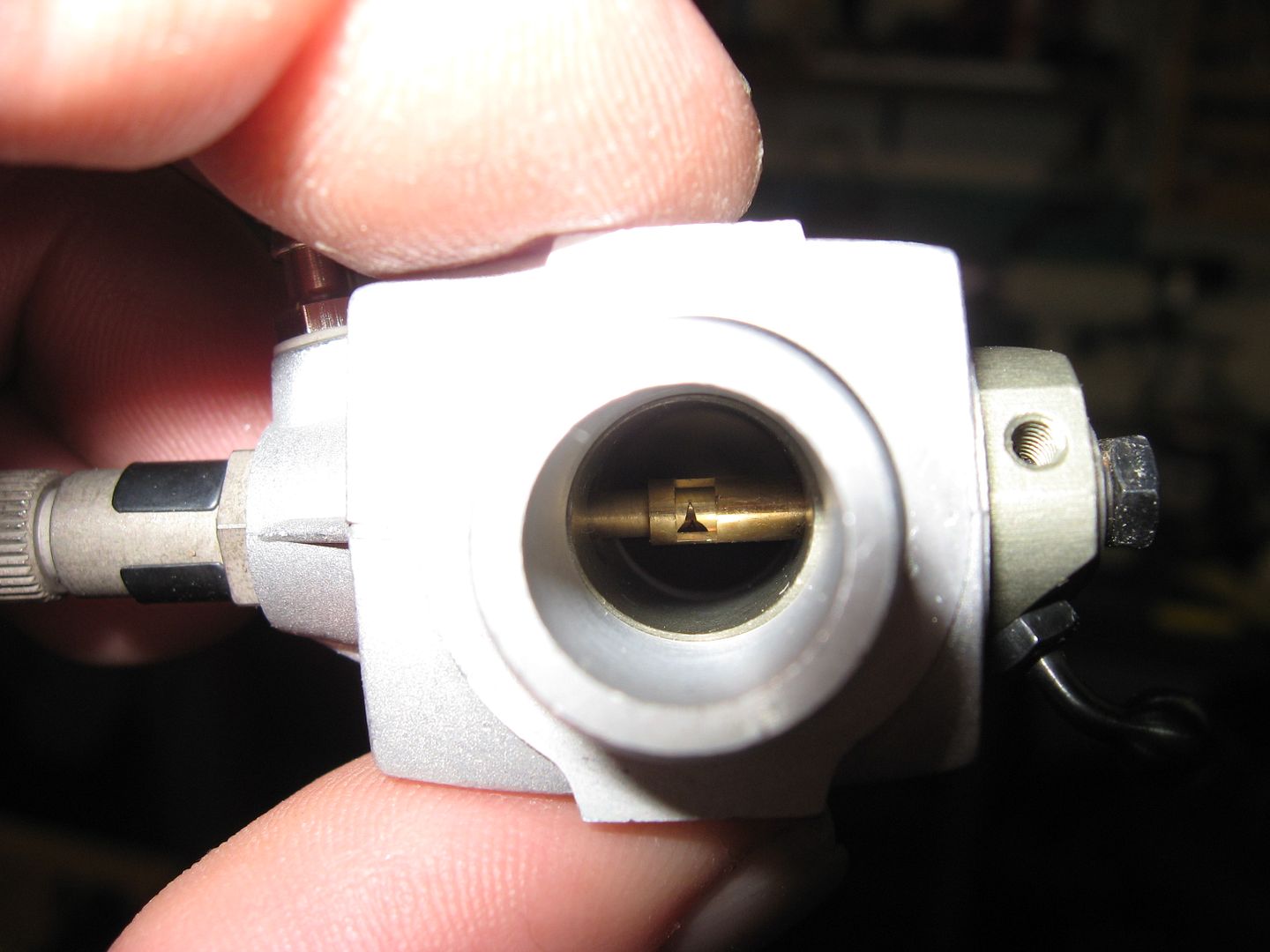

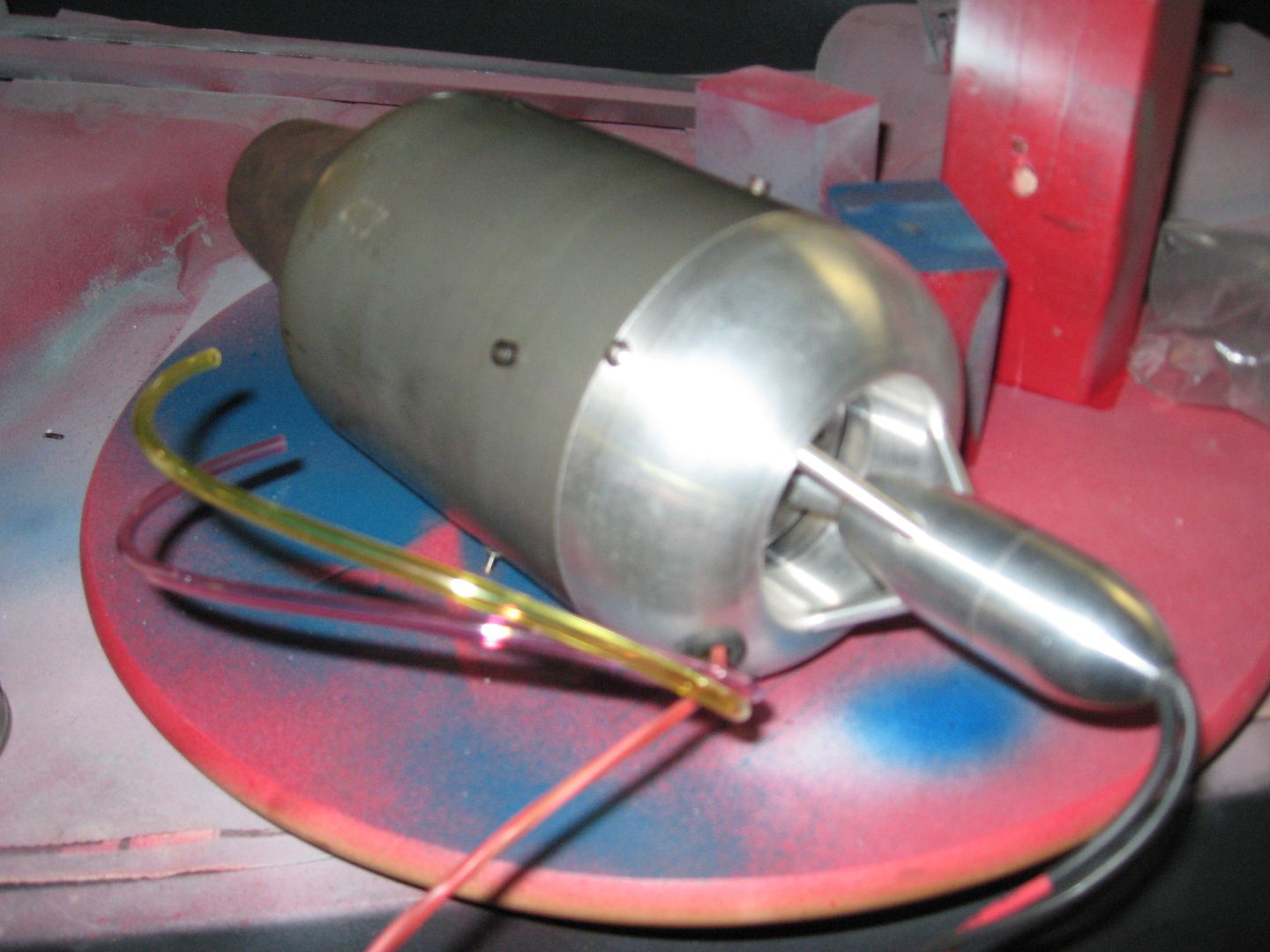

I attended the NAMES show at Wyandotte, Michigan the one year and Lee Root had his small Chevy motor operating. It had an oversized Stromberg type carb on it. I tried talking to Lee and asked him questions but he wasn't the most forthcoming person on his accomplishments. Awhile later SIC magazine published the drawings for Lee's carb. I thought, Oh boy, this is just what I need. I built the carb according to the drawings. This was more complicated than the original one I had built. Along with the float and separate fuel circuits it had an accelerator pump and choke. I got it finished and made an adapter plate for my 302. This carb required that the fuel be pressurized to get it from the fuel tank to the carb. Being new to this aspect of the hobby and not being able to gather much information about pumps I made a small piston pump, kind of like on an old Coleman stove. That part of it worked fine but I still had problems with the float sealing. Sometimes it would and sometimes not.

I got frustrated fooling with it so I moved on to other carb types. I am including several pictures of the Lee Root carb.

This evening I will continue with this discussion. My wife and I are going out for our first motorcycle ride of the season.

George

This is going to be an open discussion on carb operation and design. Everyone who has built an IC engine has used a carb, whether of their own design, a copy of another or a store bought unit.

I have been fooling with them for quite awhile and have built several different types.

When I first built my 302 engine I made up a rather sophisticated carb, by that I mean it had a float, an idle circuit, a high speed circuit and a blade type throttle plate. The first problem was getting the float to seal. The float itself was made from .002 brass shim stock and soldered together. The problem was that the float didn't have enough displacement so it didn't apply much pressure on the needle valve. I eventually eliminated it and went to a gravity feed to the carb. It worked ok but not to my liking.

I attended the NAMES show at Wyandotte, Michigan the one year and Lee Root had his small Chevy motor operating. It had an oversized Stromberg type carb on it. I tried talking to Lee and asked him questions but he wasn't the most forthcoming person on his accomplishments. Awhile later SIC magazine published the drawings for Lee's carb. I thought, Oh boy, this is just what I need. I built the carb according to the drawings. This was more complicated than the original one I had built. Along with the float and separate fuel circuits it had an accelerator pump and choke. I got it finished and made an adapter plate for my 302. This carb required that the fuel be pressurized to get it from the fuel tank to the carb. Being new to this aspect of the hobby and not being able to gather much information about pumps I made a small piston pump, kind of like on an old Coleman stove. That part of it worked fine but I still had problems with the float sealing. Sometimes it would and sometimes not.

I got frustrated fooling with it so I moved on to other carb types. I am including several pictures of the Lee Root carb.

This evening I will continue with this discussion. My wife and I are going out for our first motorcycle ride of the season.

George