arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

Well, Rocker fever has passed, but Engine Building fever definitely not...

I started on Elmer's Fancy, and will build as close to original plans as possible, but to the highest finish I can

Deviation from the original build plans will be to make shafts, holes and screws to the closest metric equivalents, I'll be using aluminium for the column and might "personalise" the flywheel.

Started with the column - turned the bottom dowel, turned space for the decorative foot, and turned the rest down to 5/8" up to the chuck as suggested by Elmer. Then laid out for the rest of the detail:

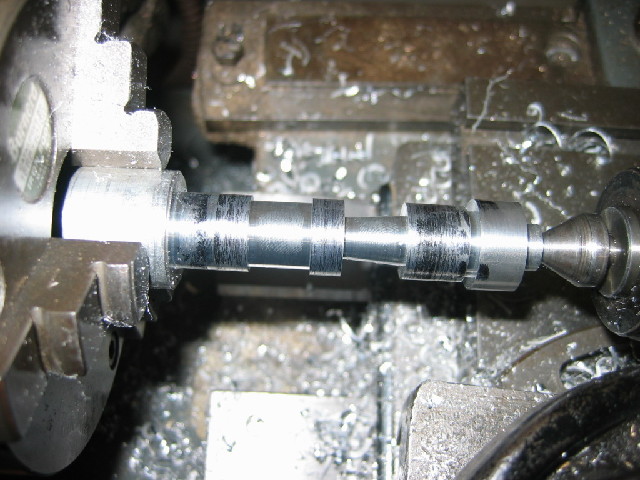

Part-way through turning the detail:

Nearly made a boo-boo on the taper bit; calculated the angle at which to set the topslide from Elmer's dimensions (nice doing trigonometry for a change), but forgot to halve it! Fortunately I realised this in time, as the initial cut angle just looked wrong.

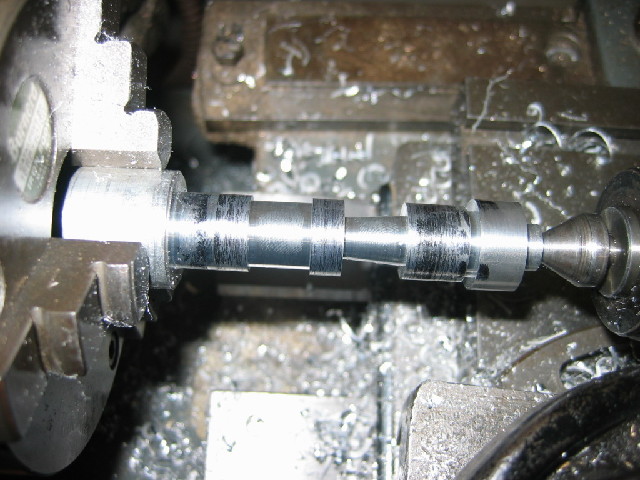

This is where I stopped tonight:

To turn the round part at the foot, I just took a piece of 6mm silver steel, drilled a 4mm hole through it at a slight angle; then used the bench grinder to grind it to shape to make a form tool. Then heat treated it and a final couple of pushes over the oilstone & it worked a treat - forgot to take a picture though.

- forgot to take a picture though.

Wanted to carry on today, but had to stop due to severe chatter & cold feet - not on the project, but on my body - It's terribly cold here in Windhoek today and my workshop's not very warm ;D

- It's terribly cold here in Windhoek today and my workshop's not very warm ;D

Regards, Arnold

I started on Elmer's Fancy, and will build as close to original plans as possible, but to the highest finish I can

Deviation from the original build plans will be to make shafts, holes and screws to the closest metric equivalents, I'll be using aluminium for the column and might "personalise" the flywheel.

Started with the column - turned the bottom dowel, turned space for the decorative foot, and turned the rest down to 5/8" up to the chuck as suggested by Elmer. Then laid out for the rest of the detail:

Part-way through turning the detail:

Nearly made a boo-boo on the taper bit; calculated the angle at which to set the topslide from Elmer's dimensions (nice doing trigonometry for a change), but forgot to halve it! Fortunately I realised this in time, as the initial cut angle just looked wrong.

This is where I stopped tonight:

To turn the round part at the foot, I just took a piece of 6mm silver steel, drilled a 4mm hole through it at a slight angle; then used the bench grinder to grind it to shape to make a form tool. Then heat treated it and a final couple of pushes over the oilstone & it worked a treat

Wanted to carry on today, but had to stop due to severe chatter & cold feet - not on the project, but on my body

Regards, Arnold