zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Thanks Trout.

Today was one of those days that make you question whether you should change jobs or not. I came home pretty upset. Okay...stinking upset. I mean P.O.'d.

So I didn't think I'd be doing anything machining wise. But I was already bummed about wasting away last night so I went at it. And I'm glad I did...I'm still pretty pissed...but at least I managed to accomplish something on my own terms. You all know what that means.

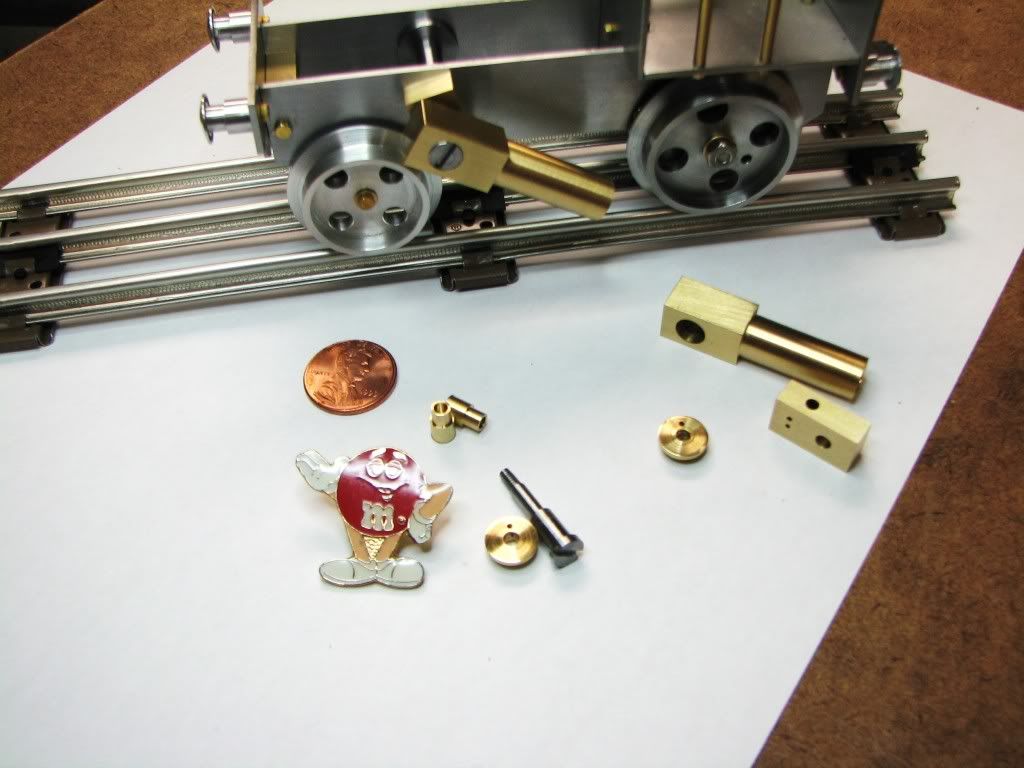

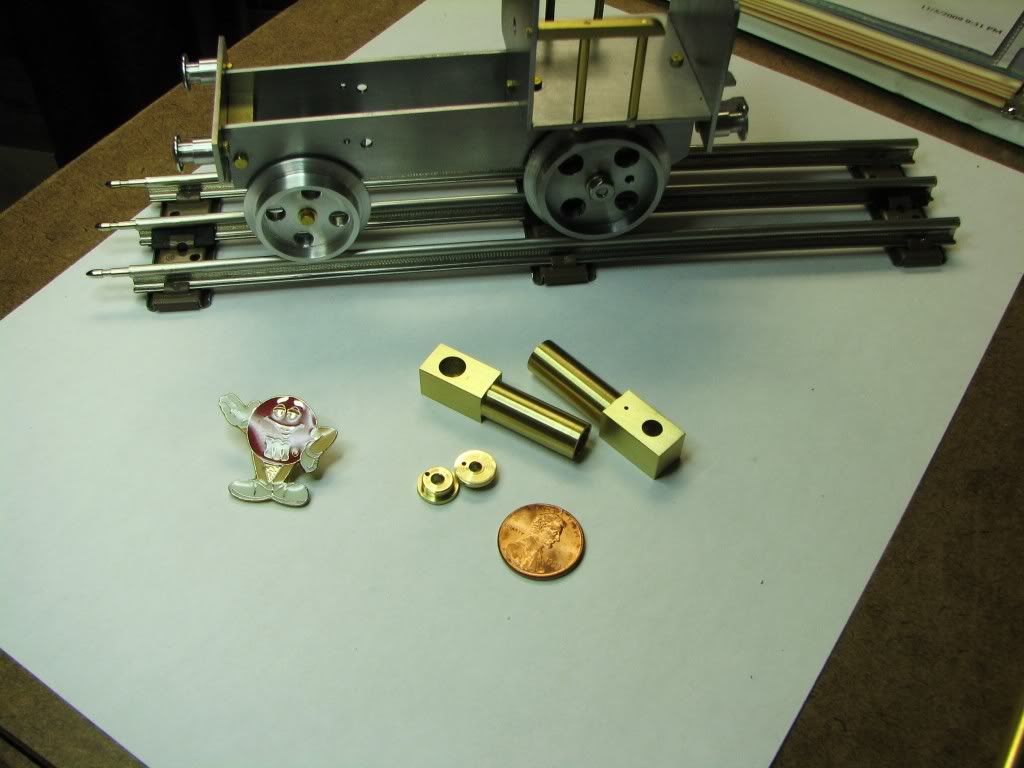

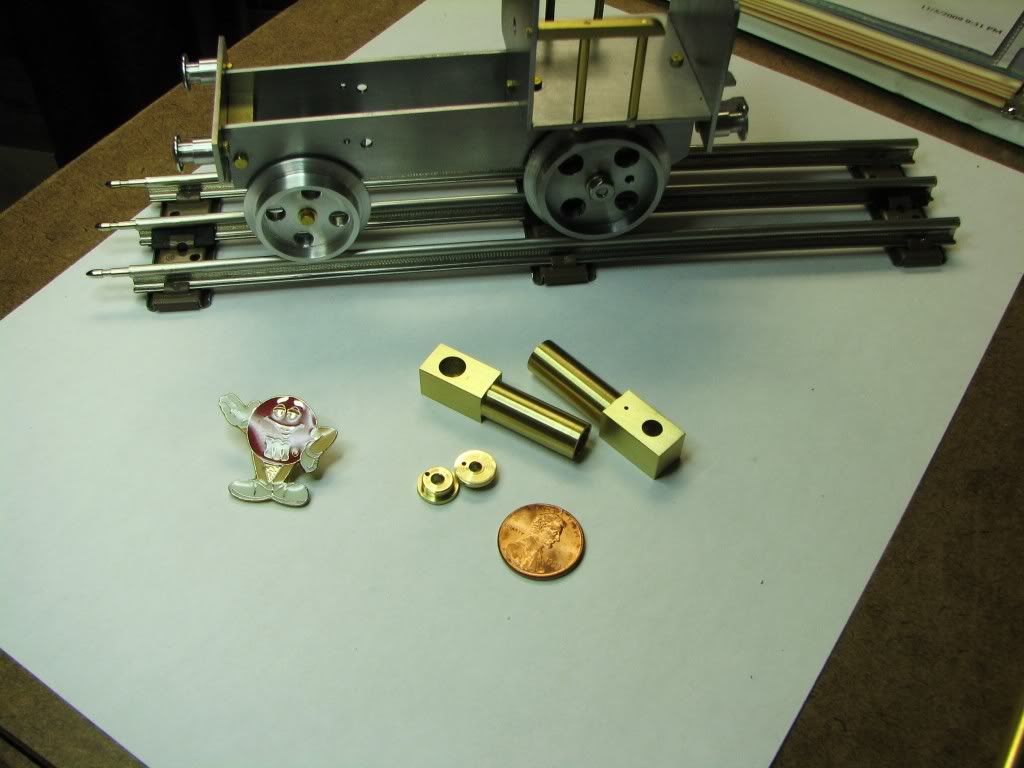

These are the cylinder covers. They are a press fit into the cylinder. I was pleased that I managed to turn them to the required diameter.

The problem was the little vent hole (0.04). Initially I tried mounting the part in the vise. That was a mistake. Crushed the sides just a tad. You might be able to tell...it's the right one. Instead I fell back on the great teachings and experience of this forum...and made a split collet from aluminum. Then it was easy.

I'm running out of lathe parts and getting closer to doing the boiler. That should be fun. All according to plan! The weather will be warm enough for me to try my hand at silver soldering outside...or at least in the garage. I didn't relish doing it in the basement...not until I have some experience. And you all know how well I do with stairs so a fast escape can't be counted on. :big:

Today was one of those days that make you question whether you should change jobs or not. I came home pretty upset. Okay...stinking upset. I mean P.O.'d.

So I didn't think I'd be doing anything machining wise. But I was already bummed about wasting away last night so I went at it. And I'm glad I did...I'm still pretty pissed...but at least I managed to accomplish something on my own terms. You all know what that means.

These are the cylinder covers. They are a press fit into the cylinder. I was pleased that I managed to turn them to the required diameter.

The problem was the little vent hole (0.04). Initially I tried mounting the part in the vise. That was a mistake. Crushed the sides just a tad. You might be able to tell...it's the right one. Instead I fell back on the great teachings and experience of this forum...and made a split collet from aluminum. Then it was easy.

I'm running out of lathe parts and getting closer to doing the boiler. That should be fun. All according to plan! The weather will be warm enough for me to try my hand at silver soldering outside...or at least in the garage. I didn't relish doing it in the basement...not until I have some experience. And you all know how well I do with stairs so a fast escape can't be counted on. :big: