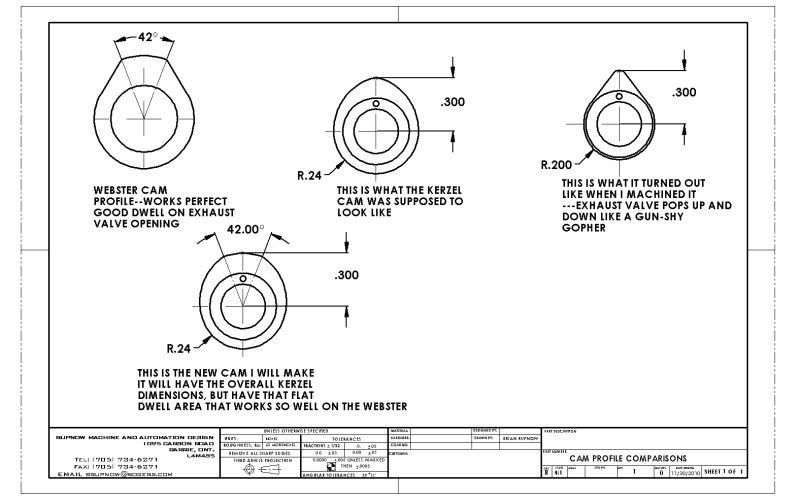

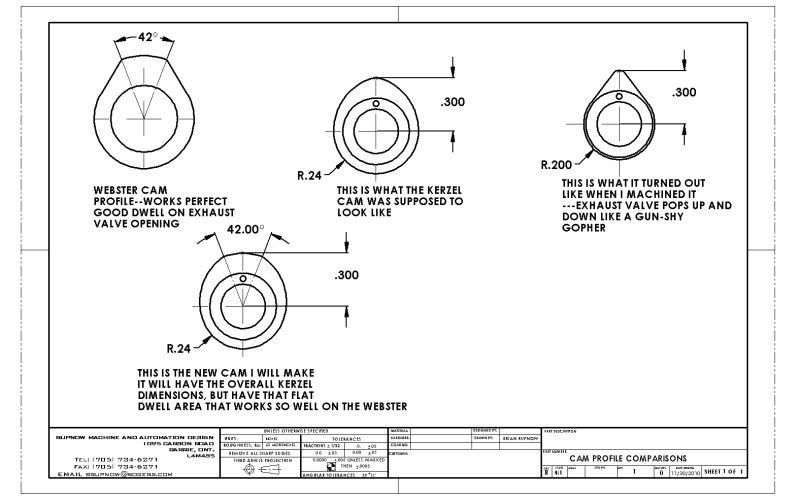

I couldn't wait. The plug works great, but the engine won't stay running. It will run as long as the electric drill is "helping" it, but it won't stay running on its own. I tried many different settings on the ignition timing and on the cam timing, and although it "wants" really bad to run on its own, it won't. There are only two possible things it can be. I don't really like the shape of the valve cam----It seems to be far to abrupt in the way it closes the exhaust valve----not so much in the way it opens it, but the fact that there is very little "dwell" on the cam, so that when the exhaust valve opens, it doesn't stay open for any amount of time, and immediately begins closing again. On the cam for the Webster, which is my only other i.c. experience, there is a fairly large "land" on the high part of the cam, so that when it opens the exhaust valve, it stays open during the entire exhaust stroke. Its easy enough to make a new cam, but first I have to address poor valve sealing which is still plaguing me. When I built the new valve cages, I re-used the old valves, knowing full well that I might have to make new valves in the future.---I even bought some 1/4" and some 3/8" drill rod to do it with. I will probably follow Chuck Fellows "step by step" of how he makes his valves out of drill rod, using a carbide lathe tool and finishes them off with a file and fine emery paper. I have never had good compression on this engine from day one, and I had excellent compression on the Webster, and it ran very easy first time I tried it. If the new valves don't get me a running engine, then I will tackle the cam.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brian Builds the Kerzel Hit and Miss I.C.

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Could it be that the center electrode isn't 'exposed' enough in the combustion chamber to initiate the flame front? I am certainly not an expert in the field of ignition but it just looks like it should be a bit more open and not up inside the end of the plug. That or the fuel charge being drawn in isn't rich enough. Man I don't know, but the suspense is killing me.

BC1

Jim

BC1

Jim

Bearcar---The plug is firing the ignition mix okay. I can hear it, I can smell burned fuel, and I can feel the "kick" on the electric drill when it fires.

Lakc

Well-Known Member

It may just be in the way that comment was written, but if its kicking against the drill, back off the timing advance a bit.Brian Rupnow said:Bearcar---The plug is firing the ignition mix okay. I can hear it, I can smell burned fuel, and I can feel the "kick" on the electric drill when it fires.

Honestly guys, I have no idea right now. I theorize---that if the engine had more compression, then when it did fire there would be much more kinetic energy created to carry the flywheels through two complete revolutions, in spite of any "stiffness" in the engine. It was definitly firing, running right along with the electric drill. Trouble was, when I disngaged the drill, the engine quickly coasted to a stop. I tried advancing and retarding the cam timing, and advancing and retarding the ignition timing, and every conceivable carburator setting. If something wasn't wrong, the engine would have ran. I pulled the sparkplug afterwards, and as I had suspected, it had been firing right along---there was a nice black layer of soot on the end of the plug. There is nothing more I can do now except make new valves, and MAYBE a different profile cam for the valves.

Lakc

Well-Known Member

I have had luck with starting fullsize engines with valve leaks by using a little compressed air through the throttle. Perhaps you could use a little negative pressure at the exhaust.

This is the tough part, and now you know why doctors cant work on their own family members. Sometimes your too close to the issue to have a clear view of the problems.

This is the tough part, and now you know why doctors cant work on their own family members. Sometimes your too close to the issue to have a clear view of the problems.

I'm pooched!!! Made two new valves today from drill rod, did the complete Chuck Fellows step by step. They looked great. Put everything back together, and compression is no different than it was before!!!! I am rapidly running out of ideas. Just for the heck of it, I tried to start the engine agin. It runs, it fires, it does all the right things, but as soon as I take the drill motor away, it runs for about 15 seconds and stops. The only things left to do are #1--build a valve seat cutter like Chuck did and see if that improves things at all, and #2--I'm going to remake the exhaust cam---I don't like the shape of the one I currently have.

- Joined

- Jan 19, 2010

- Messages

- 1,193

- Reaction score

- 41

Brian, from your earlier posts you were saying the valve does not stay open long enough.

When you turn the engine over the valve should open slightly before the bottom of the power stroke and then close at top dead center.

In my experience with the Tiny I noticed that when the cam wore down it got a lot quieter and would not run very long.

Also, I experienced some compression issues with the Tiny when the head bolt stripped out, it would still run, even though it was leaking a lot of air, and the compression was nearly unnoticeable yet it still ran.

When does the valve open and close on your's?

Kel

When you turn the engine over the valve should open slightly before the bottom of the power stroke and then close at top dead center.

In my experience with the Tiny I noticed that when the cam wore down it got a lot quieter and would not run very long.

Also, I experienced some compression issues with the Tiny when the head bolt stripped out, it would still run, even though it was leaking a lot of air, and the compression was nearly unnoticeable yet it still ran.

When does the valve open and close on your's?

Kel

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

Brian,

At the speeds the hit and miss run at the cam shape is not too critical but the open an close timing is. I have been shooting for the exhaust to start open about 5 to 10 degrees before BDC and to be fully closed a few degrees after TDC. On Tiny I am a little bit short of this, but since it is working OK I am not too worried. It is running with the exhaust starting to open at 5 degrees before BDC and is fully closed at TDC.

Gail in NM

At the speeds the hit and miss run at the cam shape is not too critical but the open an close timing is. I have been shooting for the exhaust to start open about 5 to 10 degrees before BDC and to be fully closed a few degrees after TDC. On Tiny I am a little bit short of this, but since it is working OK I am not too worried. It is running with the exhaust starting to open at 5 degrees before BDC and is fully closed at TDC.

Gail in NM

Brian Rupnow said:compression is no different than it was before!!!!

The only things left to do are #1--build a valve seat cutter like Chuck did and see if that improves things at all, and #2--I'm going to remake the exhaust cam---I don't like the shape of the one I currently have.

The compression not changing may indicate that the valves you had it it and the new valves are good.

Poor cam timing can effect compression if it is off real bad. Have you checked the timing on your cam as well as its duration? I'm not sure because I have no first hand experience with your engine but... Maybe the engine isn't getting a good breath due to the exhaust valve closing way to late?

The drawing tells it all----

stevehuckss396 said:The compression not changing may indicate that the valves you had it it and the new valves are good.

Poor cam timing can effect compression if it is off real bad. Have you checked the timing on your cam as well as its duration? I'm not sure because I have no first hand experience with your engine but... Maybe the engine isn't getting a good breath due to the exhaust valve closing way to late?

Steve---Been there, done that changed valve timing about 50 times. Changed ignition timing 50 more.

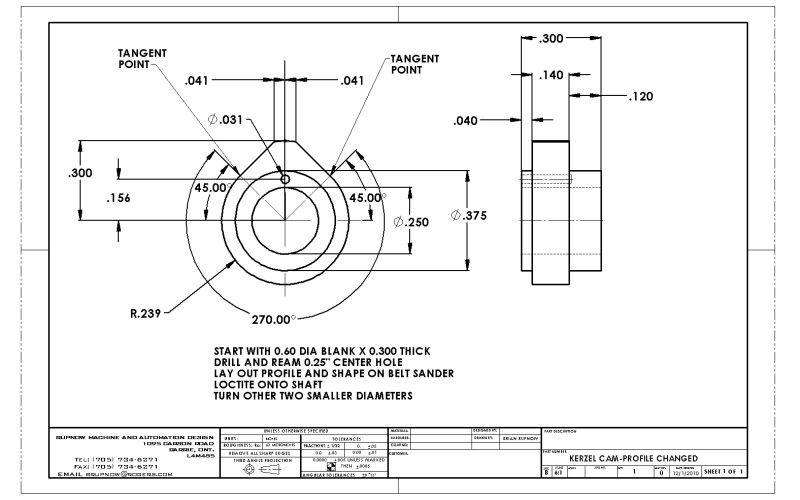

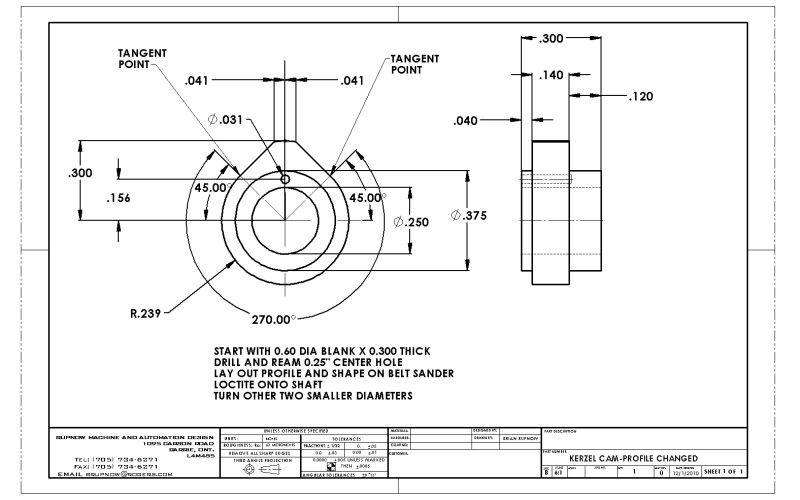

I lay in bed last night with my head on fire (Not an uncommon occurance) thinking about the math related to cam profiles.The exhaust valve should open 10 to 15 degrees before the piston reaches bottom dead center on the power stroke, and at or very slightly before the piston reaches top dead center during the exhaust stroke. Without taking "lead" and "lag" into consideration, this means that the exhaust valve should stay in its opening/open/closing/closed cycle during 180 degrees of the crankshaft rotation. Since the camshaft and exhaust cam run at exactly half the speed of the crankshaft, that means that everything that happens with the cam (in relationship to exhaust valve travel) should happen during 90 degrees of its rotation. This in turn means that there should be 270 degrees of the cam that is truly "circular" so that it has no influence on the valve during its full rotation. Based on that premise, the camshaft should look like the one I've drawn.With this configuration, if you set the valve timing so that the exhaust valve started to be influenced to open by the cam at exactly bdc, then it would be fully open at half the piston travel between bdc and tdc, and closed by the time the piston reached exactly tdc. If you set the cam timing to begin opening the exhaust valve exactly 10 degrees before bottom dead center, then it (the exhaust valve) would be fully closed exactly 10 degrees before the piston reached top dead center on the exhaust stroke. The cam profile would look exactly as shown in the drawing.---Any comments??

Tumbletown

Member

- Joined

- Jul 25, 2010

- Messages

- 7

- Reaction score

- 0

Brian

You have 90 degrees between the tangent points. If you widened that to 95 degrees wouldn't you then have 190 degree cam action which can be adjusted to 10 degree BDC to TDC....

Or am I not thinking straight?

Adrian

You have 90 degrees between the tangent points. If you widened that to 95 degrees wouldn't you then have 190 degree cam action which can be adjusted to 10 degree BDC to TDC....

Or am I not thinking straight?

Adrian

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

Brian,

You might want to widen the 90 degrees out some to allow for valve lash (clearance). As I recall the follower is a ball bearing on the Kerzel. With your CAD, place the follower in position and allow whatever clearance you desire between the base diameter on the cam and the OD of the follower. I use about 0.008 inches. Then rotate the cam to make contact with the flank and the follower. Twice this rotation angle will get subtracted from the cam as drawn. It is a significant amount with a roller cam.

Gail in NM

You might want to widen the 90 degrees out some to allow for valve lash (clearance). As I recall the follower is a ball bearing on the Kerzel. With your CAD, place the follower in position and allow whatever clearance you desire between the base diameter on the cam and the OD of the follower. I use about 0.008 inches. Then rotate the cam to make contact with the flank and the follower. Twice this rotation angle will get subtracted from the cam as drawn. It is a significant amount with a roller cam.

Gail in NM

Brian, I think what you've said is right (I understand it anyway) and the new profile should work. That is very similar to the webster except that maybe has a slightly longer duration. As Adrian says, you could widen that duration to open a little before BDC and shut a little after TDC in line with Gail's comments.

Those 5 degrees or so before BDC and after TDC you are not gaining anything by having the exhaust closed as the piston is hardly moving, so it won't be giving you any more power just before BDC and it won't have started to open the inlet just after TDC. However, you will exhaust more efficiently by having it open in those periods though (I think) is that right Gail?

Nick

Those 5 degrees or so before BDC and after TDC you are not gaining anything by having the exhaust closed as the piston is hardly moving, so it won't be giving you any more power just before BDC and it won't have started to open the inlet just after TDC. However, you will exhaust more efficiently by having it open in those periods though (I think) is that right Gail?

Nick

Similar threads

- Replies

- 413

- Views

- 42K

- Replies

- 356

- Views

- 56K