- Joined

- Jan 19, 2010

- Messages

- 1,193

- Reaction score

- 41

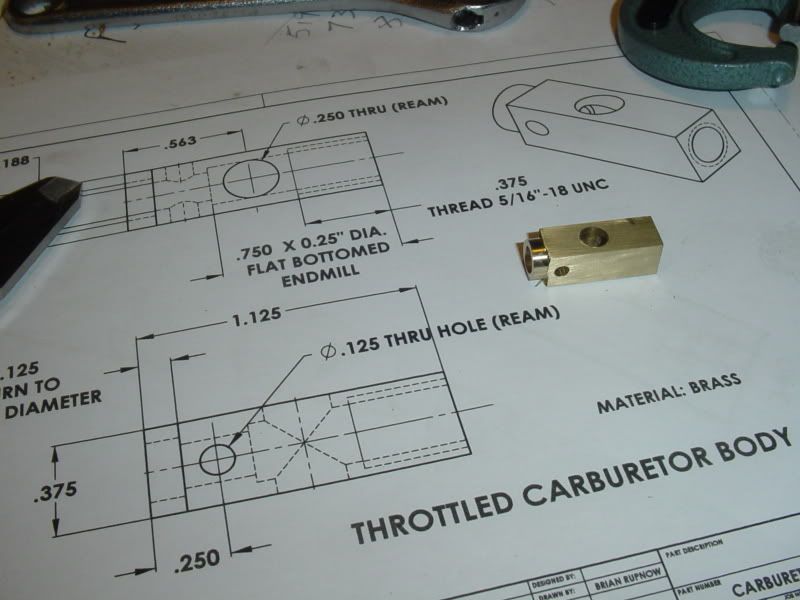

Great Job on the carb design.

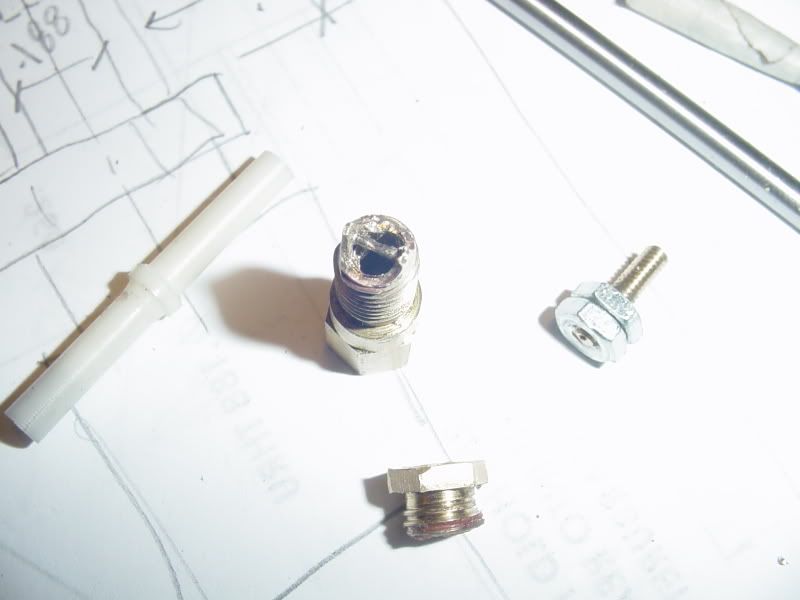

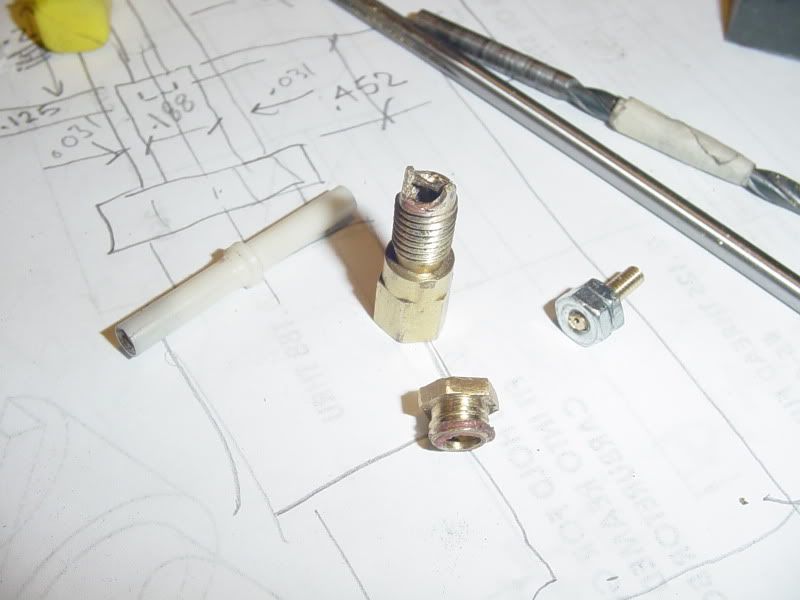

FWIW, I ended up putting a spring between the hex nut on the throttle and the carburetter body. At first it held in place by itself, but I think over time it loosened up, and someway to keep the throttle in place was needed. Hens the spring. Perhaps just keeping slight pressure on the throttle nut is all that is needed.

I also noticed a difference in the engines performance. When I had the throttle in the 1/2-3/4 range, the engine ran smoother than at wide open throttle. I think this adds turbulence to the air/fuel ratio and helps mix the mixture a little better.

Kel

FWIW, I ended up putting a spring between the hex nut on the throttle and the carburetter body. At first it held in place by itself, but I think over time it loosened up, and someway to keep the throttle in place was needed. Hens the spring. Perhaps just keeping slight pressure on the throttle nut is all that is needed.

I also noticed a difference in the engines performance. When I had the throttle in the 1/2-3/4 range, the engine ran smoother than at wide open throttle. I think this adds turbulence to the air/fuel ratio and helps mix the mixture a little better.

Kel