sunworksco

Rocket Man

- Joined

- Nov 20, 2010

- Messages

- 242

- Reaction score

- 13

Being a plumbing contractor for 34 years now, I have known that it is not a good practice to mix dissimilar metals due to electrolysis.

How is this different with boilers?

What pressures can your boiler be operated?

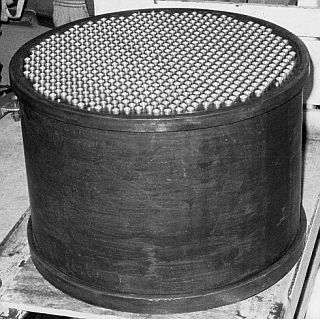

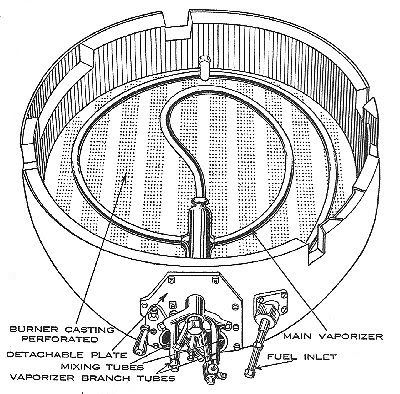

Since I am building a vertical 7.5" diameter x 4.5" height boiler, would it be practical to build it with your methods or fabricate the entire boiler out of copper?

BTW, your craftsmanship is superb!

Regards,

Giovanni

How is this different with boilers?

What pressures can your boiler be operated?

Since I am building a vertical 7.5" diameter x 4.5" height boiler, would it be practical to build it with your methods or fabricate the entire boiler out of copper?

BTW, your craftsmanship is superb!

Regards,

Giovanni