BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

There's an excellent thread over on PM about blue chips and carbide tooling:

http://www.practicalmachinist.com/vb/showthread.php?t=154429

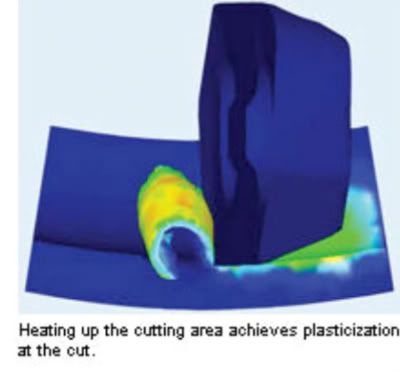

The point they're making, that the blue chips take the heat away from the workpiece, is a point I've tried to make, but people are skeptical. The amazing thing is that with the right tooling, you can do this very nicely on little home machines like my 9x30 lathe, or the flycutter on my mill. It's only appropriate for carbide. For HSS tooling, straw color is about as hot as you'd want it, and you're not pulling the heat out in the chips in the same way. It's also only relevant to steel since aluminum doesn't turn blue!

To give an idea, when I flycut the steel table for my disc sander, these are typical of the chips I was getting and their color:

I was using a brazed carbide tool for the operation. Could've done with better chip formation, but the brazed carbide tool is not the ideal geometry for flycutting as we've discussed elsewhere. On the lathe, I would be getting perfect blue 6's and 9's.

You do have to be careful because those little blue devils are hot! You want closed collar, no pockets or cuffs, really good eye protection, and maybe a hat too. I'd also keep on eye on where they're landing. Don't know if they could start a fire, but oily rags and blue chips seem like they ought not to be allowed to get together.

OTOH, after a fly cutting pass, the surface of the steel was not even warm to my touch. I used very little coolant either, just a little heavy sulfurized cutting oil, one good swipe with a brush at the beginning of each pass.

Cheers,

BW

http://www.practicalmachinist.com/vb/showthread.php?t=154429

The point they're making, that the blue chips take the heat away from the workpiece, is a point I've tried to make, but people are skeptical. The amazing thing is that with the right tooling, you can do this very nicely on little home machines like my 9x30 lathe, or the flycutter on my mill. It's only appropriate for carbide. For HSS tooling, straw color is about as hot as you'd want it, and you're not pulling the heat out in the chips in the same way. It's also only relevant to steel since aluminum doesn't turn blue!

To give an idea, when I flycut the steel table for my disc sander, these are typical of the chips I was getting and their color:

I was using a brazed carbide tool for the operation. Could've done with better chip formation, but the brazed carbide tool is not the ideal geometry for flycutting as we've discussed elsewhere. On the lathe, I would be getting perfect blue 6's and 9's.

You do have to be careful because those little blue devils are hot! You want closed collar, no pockets or cuffs, really good eye protection, and maybe a hat too. I'd also keep on eye on where they're landing. Don't know if they could start a fire, but oily rags and blue chips seem like they ought not to be allowed to get together.

OTOH, after a fly cutting pass, the surface of the steel was not even warm to my touch. I used very little coolant either, just a little heavy sulfurized cutting oil, one good swipe with a brush at the beginning of each pass.

Cheers,

BW