Train_Fan

Active Member

- Joined

- Apr 16, 2013

- Messages

- 25

- Reaction score

- 8

Hi all,

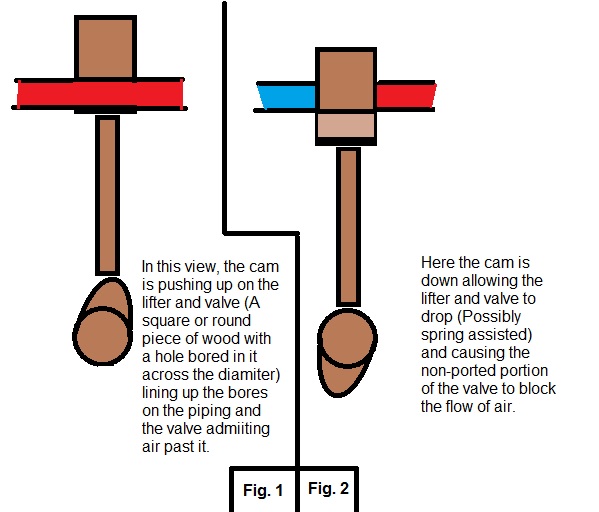

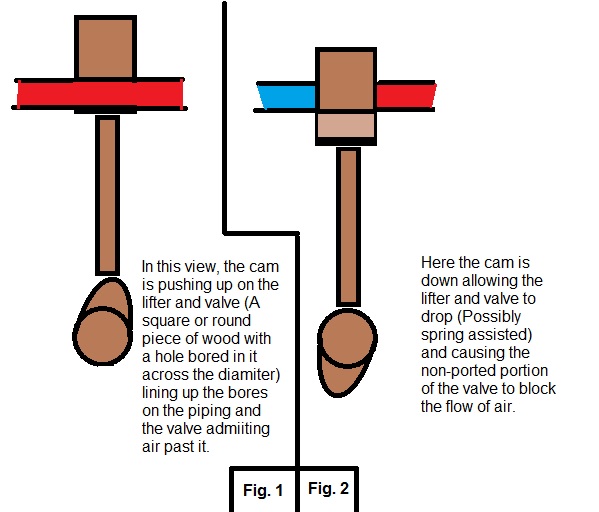

For my next project I plan on making a straight 3 engine out of wood, using actual ball bearings that I have en masse and for operation off of pressure not volume.

My one roadblock is that I plan to make this as close to an auto engine as I can, and therefore intend to use camshafts and lifters for intake and exhaust, but I cannot feasibly implement rockers and normal "valves" at this time. So I have turned to you for some design input.

My idea is as follows, drawn up in my handy CAD program "Microsoft Paint":

Given higher-ish pressures of ~20psi and under, would this be the best design given the fact that would be made of maple/cherry?

Thanks much,

TF

For my next project I plan on making a straight 3 engine out of wood, using actual ball bearings that I have en masse and for operation off of pressure not volume.

My one roadblock is that I plan to make this as close to an auto engine as I can, and therefore intend to use camshafts and lifters for intake and exhaust, but I cannot feasibly implement rockers and normal "valves" at this time. So I have turned to you for some design input.

My idea is as follows, drawn up in my handy CAD program "Microsoft Paint":

Given higher-ish pressures of ~20psi and under, would this be the best design given the fact that would be made of maple/cherry?

Thanks much,

TF