Train fan.

I have noticed you have not had any feedback on you post.

I think many of us are speechless an not sure what to say.

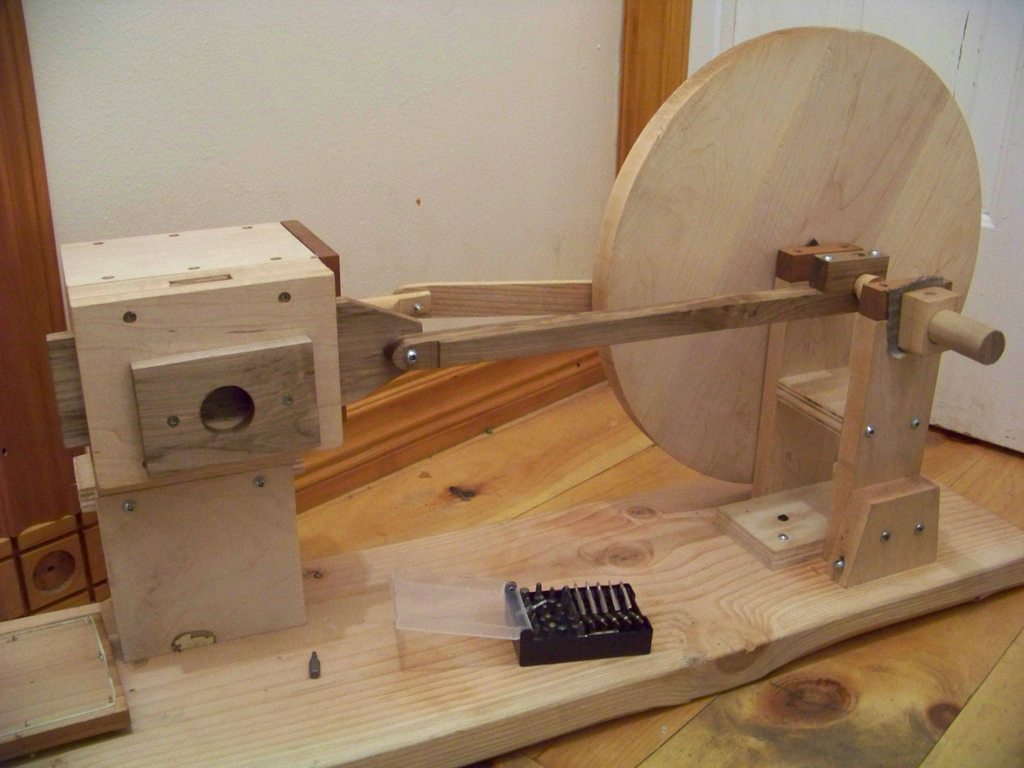

So first order of business let me congratulate you on your first build. And it runs. Fantastic.

Thanks!

Eh, its not that much of a gimmick so I didn't really expect a large bandwagon out on the plains to meet me.

You are not the first young man to have an idea and make it out of wood. the famous Sam colt carved his first prototype for his revolvers out of wood as I recall he was traveling on a ship at the time.

I will also say you deserve a pat on the back for posting a photo here.

It can be risky business to show your handwork to the world or even family.

IMHO all of us here have received that is nice but what does it do !Or for us married guys that is nice but when are you going to fix the _________?

That is pretty awesome to know! I knew wooden prototypes were a handy thing but a wooden peacemaker, now thats an idea!

And I know this quite well, thanks though.

Some of my projects go over like a lead zeppelin while the oddest ones get mounds of praise. Later this summer I'll show a reclaimed hay-wagon-wood end table I am also working on as an aside (obviously not in the engines subforum though!

)

I think we could also give a long list of possible deign improvements.

But that too could come of as criticism.

Nope, I'm quite used to it. Fire away if you got it, any learning is learning.

My first question is how are you feeding air into it. my second is What do you plan on doing for a Next project and third how did you set the valve timing . How hard was it to get it right.

And when you are ready to ask for help just fire away.

Tin

Well, I am using a vacuum for the interim as I have no volume-oriented pressure supplies. By applying it either to the inlet or exhaust it can run either direction.

Next project? If I can have a friend turn me some pistons, maybe a straight 2, or if not maybe a wobbler. From there I intend to make a little pumpjack to run off these.

Valve timing was literally trial and error. I had an idea of what was needed, so I just eyeballed it with a steel rule until I got the valve port spacing right (Many scrap pine trials were made). From there I kept the flywheel loose on "crankshaft" and slipped it back and forth until the strokes of the valves were in line with the piston, then made some runs with a vacuum to fine tune it. Took all of 10 minutes for that really. For a first time not as hard as I thought, though I did learn to space out the accompanying ports on the valve body. I have them too close for an efficient valve action.

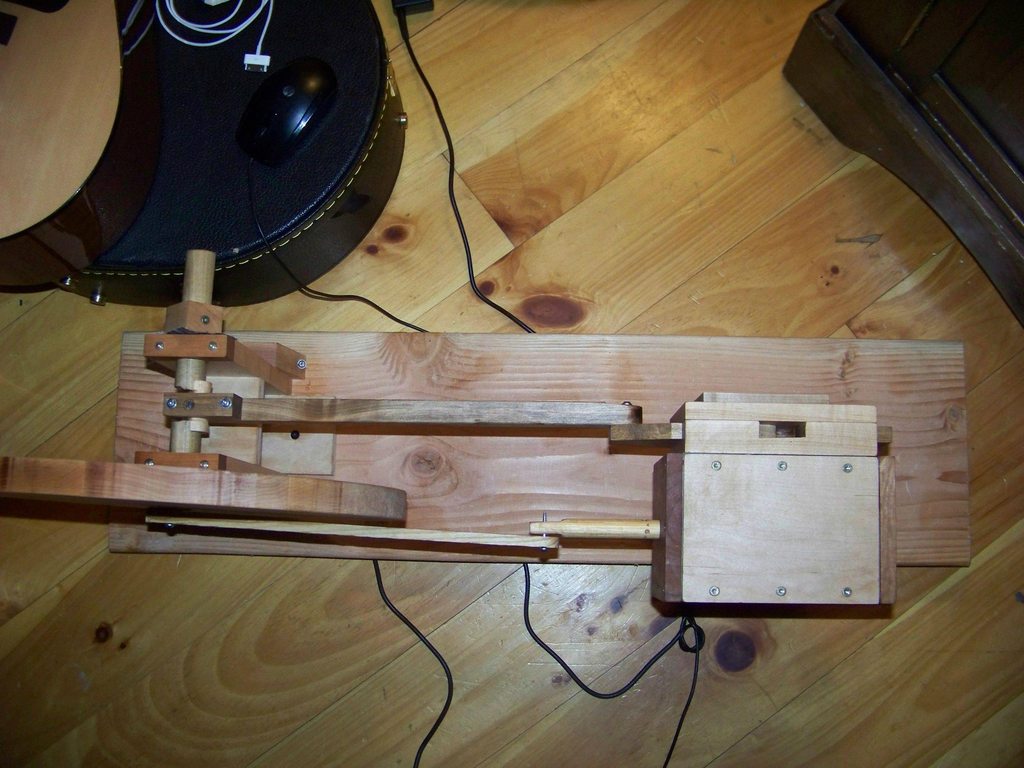

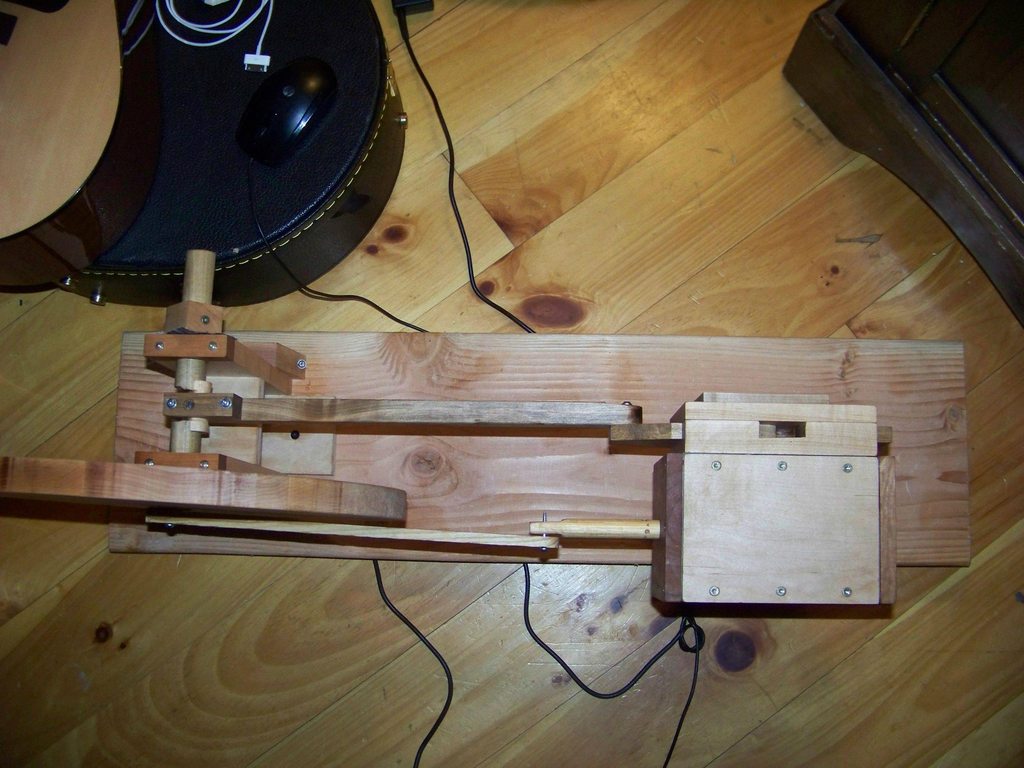

Here are some pics of the valve mech, starting with the outside with the inlet:

The valve. I shold take the rest of the stock that came from and make a jewelry box for the GF. :

The ports leading to the cylinder (The air passes through the holes to passages milled in the back of the piece to inlets in the cylinder)

The inlets, bottom for intake, top for exhaust.

_________________________________________________

I for one would like to see how you constructed the piston and cylinder. Job well done. Thm:

I used about 3/4" hard maple for the cylinder. I buzzed out two pieces at 3-2/64th" and mated them to the insides of pieces cut to 4-1/16th" for an inside dimension of 3X3. Drilled and countersunk some holes for screws and screwed them together.

The heads are 1/2" cherry, though I accidentally used some nice figured stuff for them instead of knife handles. :wall: Oh well.

I used waxed binding string (Used in IT and all for securing cable bundles.

http://www.mainethread.com/waxed_cord.html) for all seals and gaskets. It is all finished and lubricated with standard drug store mineral oil.

_________________________________________________________

To the rest, Thanks much!

For a first moving project it came out well in my opinion, surely not to par to the rest I've seen here (Again IMHO. I'm a humble lad). Metal is a class of its own, I can't compete!.

Wood has its quirks, but as does brass, steel and titanium, no? I'd say Beech or Basswood is the brass of woods, soft and easily formed though gummy. Steel? Oak, common, strong and easy to work with. Titanium? One of the more exotic woods I'd say but I have no experience with them. Its all the same, we remove material till its a finished product but the real task is learning how in each of our mediums.