arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

I've been out of the shop for quite a while now due to non-shop-related burn injuries to both my hands. After spending a most frustrating 5 weeks just watching TV and waiting for things to heal up, I'm ready for the shop again, and wanted a fairly simple project to get back into the swing of things.

I tossed a number of Elmer's engines in a hat, and drew #43 ;D

Once again, I'll be using metric fasteners and shafting to suit my needs, and I won't necessarily be making all pieces exactly to Elmer's plans.

On Friday I started assembling whatever I could scrounge to start the build:

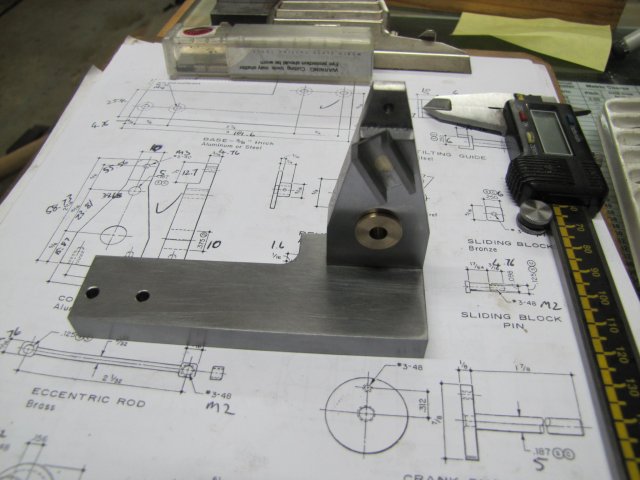

Friday afternoon saw the base done from some hot-rolled steel bar:

The column followed on Saturday - also from hot-rolled; I went for a single angled side on each side instead of having a parallel bit at the top of the column. I just used a pair of drills to get a suitable angle to mill it off at:

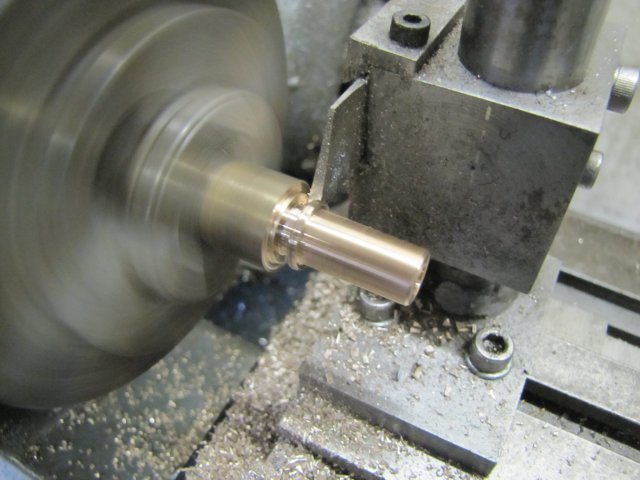

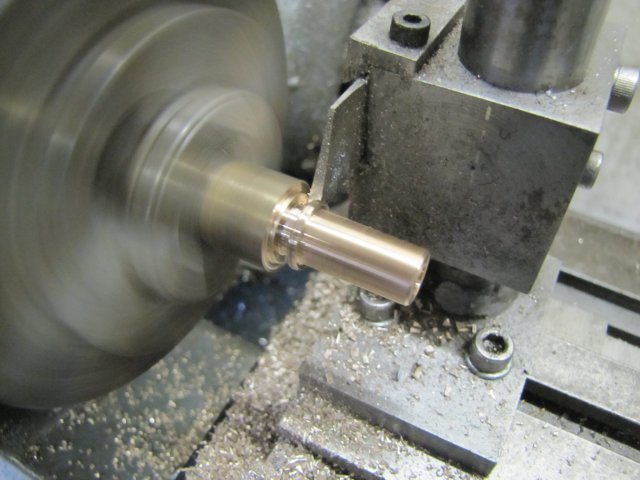

Main bearing was a very quick turning, reaming and parting job from phosphor bronze:

Instead of making the reversing slide from solid, I turned up a bit of brass to 5mm diameter, and drilled a 5mm hole with a generous chamfer into a bit of steel off-cut:

Out with the torch and the silver solder, and joined together:

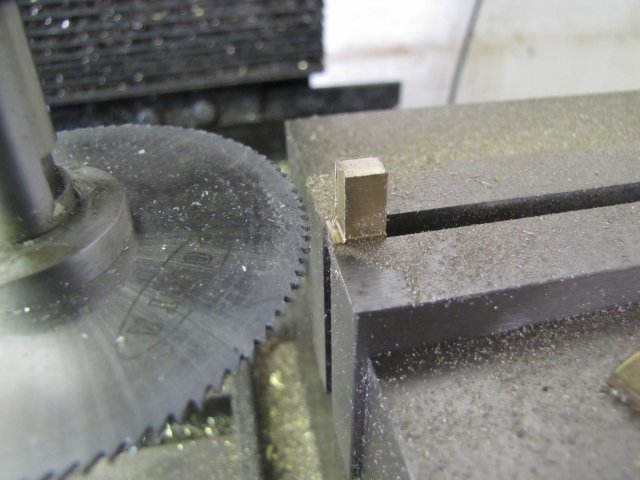

Then I just mounted the lot in the collet chuck on the rotary table, and milled out the slot in the steel bit:

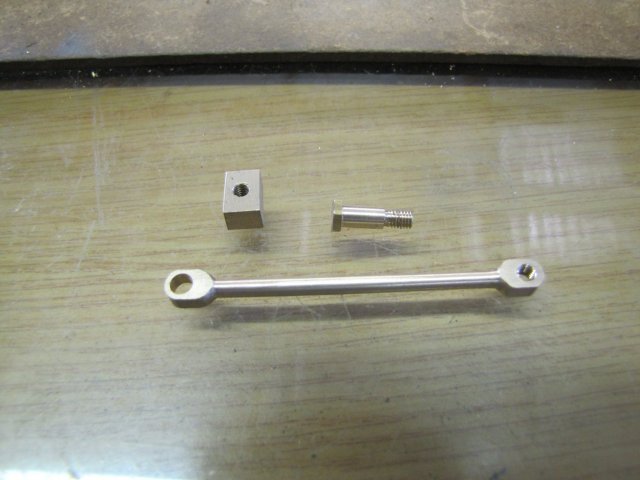

For Saturday, I ended up with this handful of bits; not much, but some progress:

At least the whole lot fits together like it should :big::

This morning, I started with the reverse lever - just laid it out, centered the RT on the mill, mounted the fixture plate, and clamped the workpiece to that on top of some scrap aluminium, and centered on the pivot hole:

A little while later, after some judicious drilling and milling:

Then I turned up a bush to fit the hole drilled in the reversing lever and to fit the reversing slide's shaft:

And silver soldered the two together and cleaned things up a bit:

Zee's bane followed... A bit of ornamental turning and shaping with a small file:

Screwed into a nut, heated bright red hot on the thin part with a small torch, and bent over with gentle pressure from a bit of flat steel while keeping the stem red-hot. Bent like a charm ;D:

Trying to get a bit of a polish on the inside of the corner is a problem, but some rope (the type that butchers use to tie up a roast) dipped in metal polish quickly gets into the back bits:

Handle done:

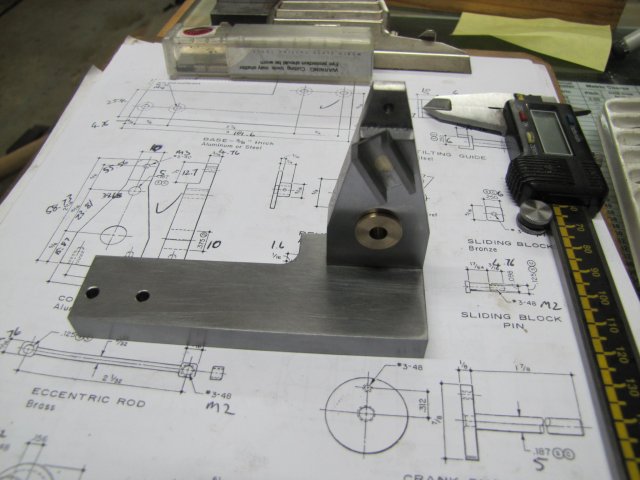

And today's assembly shot:

Regards, Arnold

I tossed a number of Elmer's engines in a hat, and drew #43 ;D

Once again, I'll be using metric fasteners and shafting to suit my needs, and I won't necessarily be making all pieces exactly to Elmer's plans.

On Friday I started assembling whatever I could scrounge to start the build:

Friday afternoon saw the base done from some hot-rolled steel bar:

The column followed on Saturday - also from hot-rolled; I went for a single angled side on each side instead of having a parallel bit at the top of the column. I just used a pair of drills to get a suitable angle to mill it off at:

Main bearing was a very quick turning, reaming and parting job from phosphor bronze:

Instead of making the reversing slide from solid, I turned up a bit of brass to 5mm diameter, and drilled a 5mm hole with a generous chamfer into a bit of steel off-cut:

Out with the torch and the silver solder, and joined together:

Then I just mounted the lot in the collet chuck on the rotary table, and milled out the slot in the steel bit:

For Saturday, I ended up with this handful of bits; not much, but some progress:

At least the whole lot fits together like it should :big::

This morning, I started with the reverse lever - just laid it out, centered the RT on the mill, mounted the fixture plate, and clamped the workpiece to that on top of some scrap aluminium, and centered on the pivot hole:

A little while later, after some judicious drilling and milling:

Then I turned up a bush to fit the hole drilled in the reversing lever and to fit the reversing slide's shaft:

And silver soldered the two together and cleaned things up a bit:

Zee's bane followed... A bit of ornamental turning and shaping with a small file:

Screwed into a nut, heated bright red hot on the thin part with a small torch, and bent over with gentle pressure from a bit of flat steel while keeping the stem red-hot. Bent like a charm ;D:

Trying to get a bit of a polish on the inside of the corner is a problem, but some rope (the type that butchers use to tie up a roast) dipped in metal polish quickly gets into the back bits:

Handle done:

And today's assembly shot:

Regards, Arnold