- Joined

- Oct 1, 2010

- Messages

- 1,342

- Reaction score

- 395

About a year after I got my mill-drill, I started coveting rotary table and bought this one with dividing plates but without a tailstock (I am on a budget, and what is best bang-for-buck).

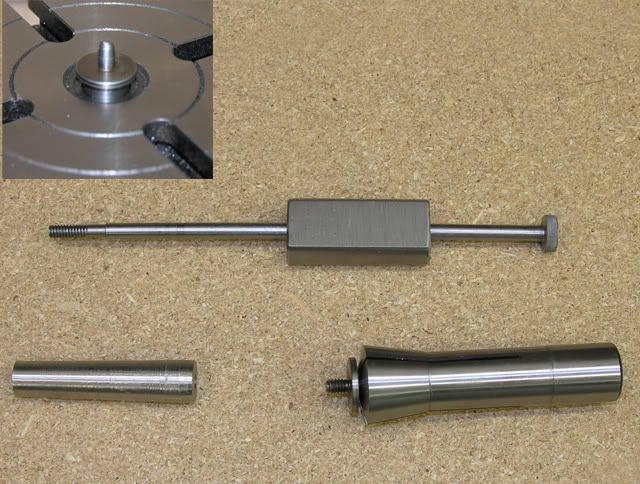

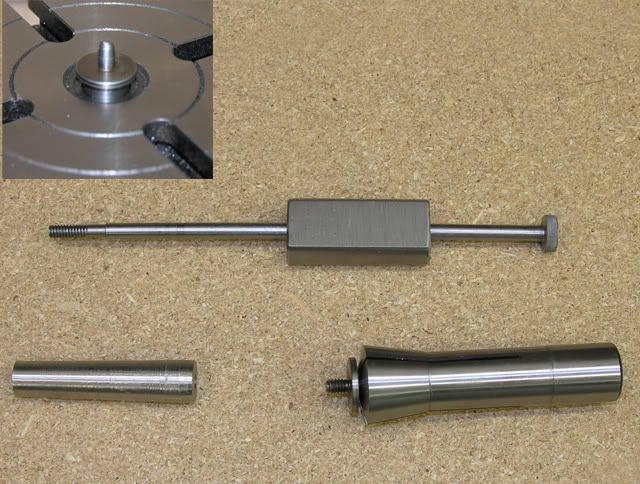

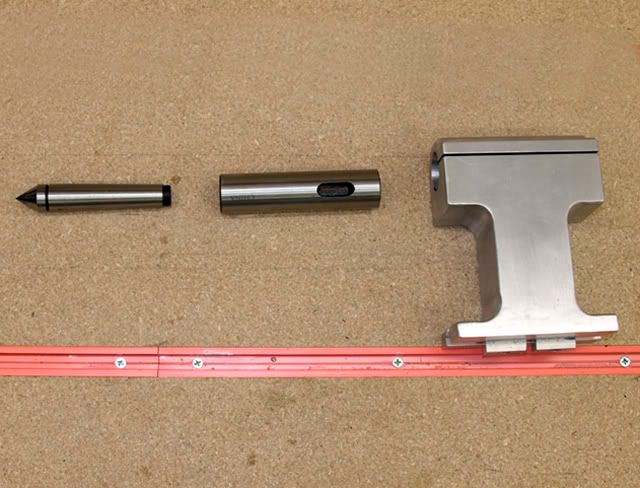

I saw someone's idea to make a locating jig (my apologies for not giving due credit: I couldn't find the post).

I turned a MT2 taper (poorly, but it clocks out OK: I used 304 SS and found out something else would have been easier to work with. I also copied the idea to make a small slide-hammer to pull the taper. Female threads on taper and male threads on accessories are 1/4-20: I used taps and dies because goal of this was to make the jig rather than practice machining skills.)

Cute discovery for this was the slide-hammer shaft. I wanted a knob to knurl. and It occured to me I had something that was close to what I wanted:

MAKING A TAILSTOCK

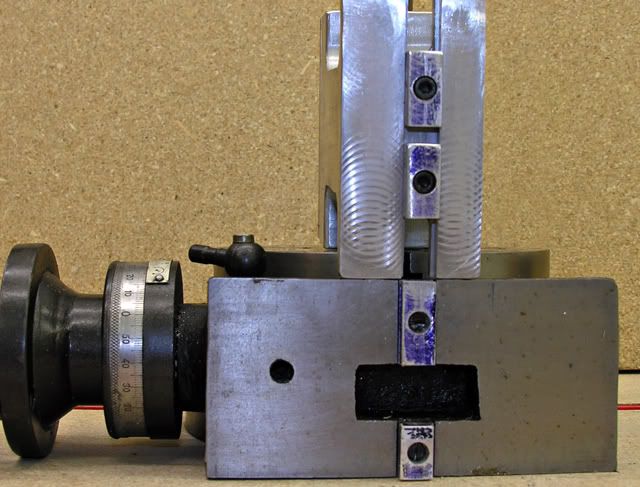

I got this idea late one night and decided to practice some skills. I wanted something for occasional use and "shim, tap, and tighten" adjustments would be alright.

I started with a hefty chunk of 4 x 6 6061 for this (I am learning, so I am buying "known" materials.) Lots of measure, cut, measure, cut, set-it-up, etc.

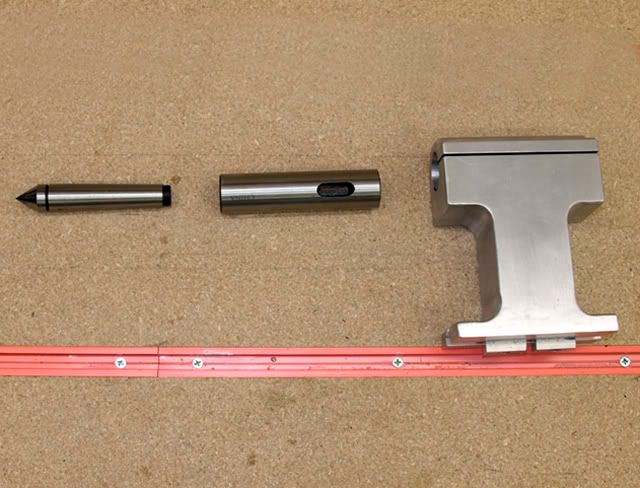

What made this easy was the MT2 from straight-hole (1-inch) adapter that was on sale at ENCO.

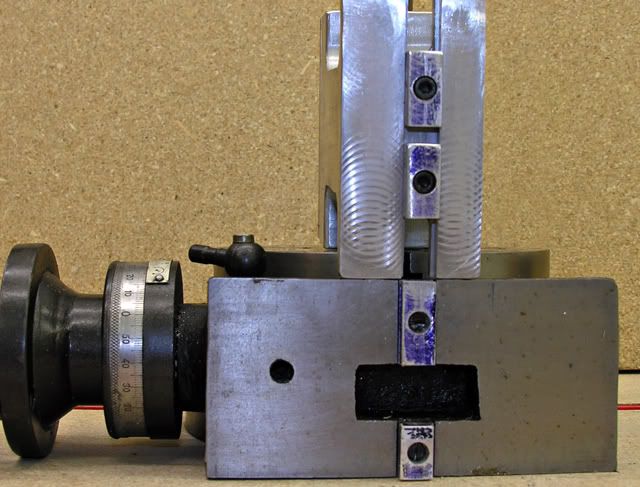

The main thing that was fiddly with this was boring the socket in the aluminum. I figured my boring bar would flex, so went undersized, then finished with a lot of honing to size with a brake-cylinder hone. the last thing I did was use a slitting saw to cut the slit. I made Go-NoGo guages to measure the bore.

The tailstock and RT are both keyed to my mill slots: I did this by trial and error. The keyways on the RT and the tailstock are wider than the mill-table slots, so the keys are actually T-shaped.

I don't think I would have thought of any of this before I discoverd and regularly lurked on this forum. Thanks.

I saw someone's idea to make a locating jig (my apologies for not giving due credit: I couldn't find the post).

I turned a MT2 taper (poorly, but it clocks out OK: I used 304 SS and found out something else would have been easier to work with. I also copied the idea to make a small slide-hammer to pull the taper. Female threads on taper and male threads on accessories are 1/4-20: I used taps and dies because goal of this was to make the jig rather than practice machining skills.)

Cute discovery for this was the slide-hammer shaft. I wanted a knob to knurl. and It occured to me I had something that was close to what I wanted:

MAKING A TAILSTOCK

I got this idea late one night and decided to practice some skills. I wanted something for occasional use and "shim, tap, and tighten" adjustments would be alright.

I started with a hefty chunk of 4 x 6 6061 for this (I am learning, so I am buying "known" materials.) Lots of measure, cut, measure, cut, set-it-up, etc.

What made this easy was the MT2 from straight-hole (1-inch) adapter that was on sale at ENCO.

The main thing that was fiddly with this was boring the socket in the aluminum. I figured my boring bar would flex, so went undersized, then finished with a lot of honing to size with a brake-cylinder hone. the last thing I did was use a slitting saw to cut the slit. I made Go-NoGo guages to measure the bore.

The tailstock and RT are both keyed to my mill slots: I did this by trial and error. The keyways on the RT and the tailstock are wider than the mill-table slots, so the keys are actually T-shaped.

I don't think I would have thought of any of this before I discoverd and regularly lurked on this forum. Thanks.