BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

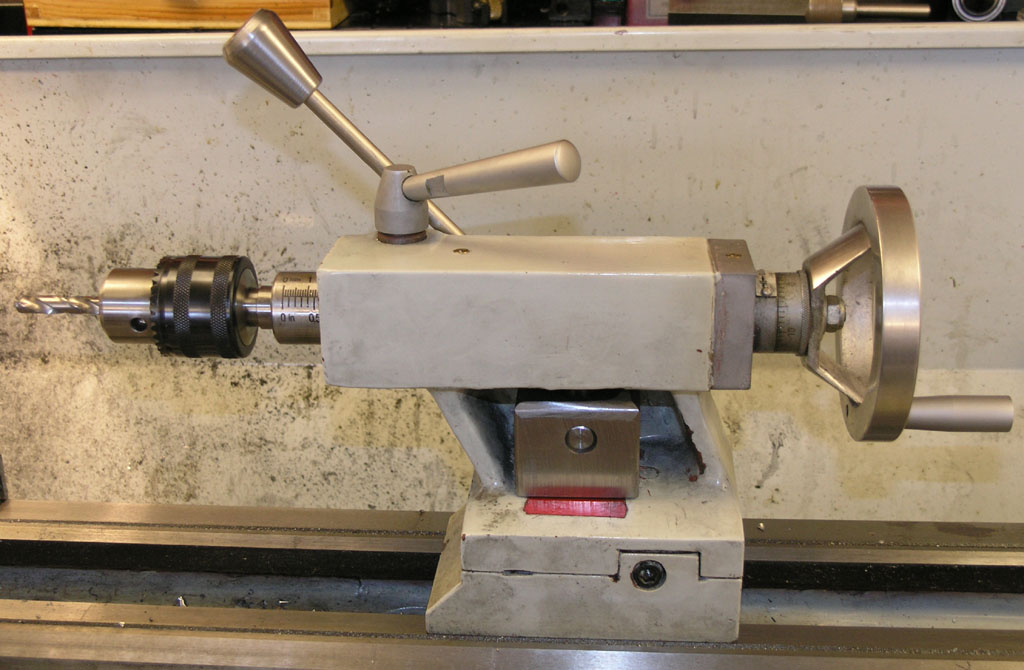

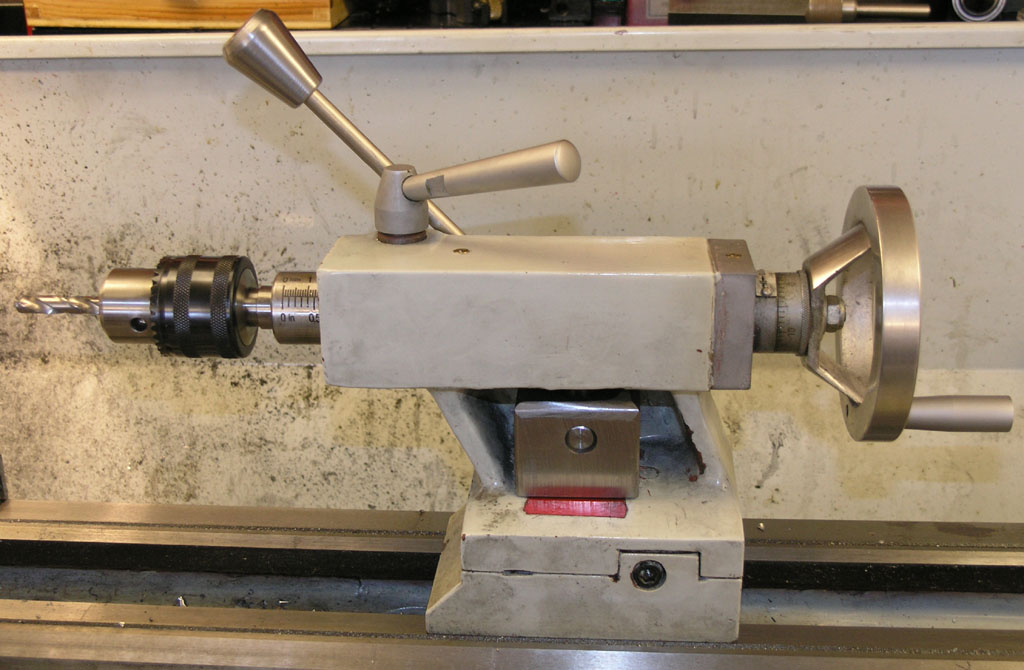

Here's an easy project that makes the tailstock nicer to use: no more scratching around for a wrench:

More details on my web site:

http://www.cnccookbook.com/CCLatheTailLock.htm

Cheers,

BW

More details on my web site:

http://www.cnccookbook.com/CCLatheTailLock.htm

Cheers,

BW