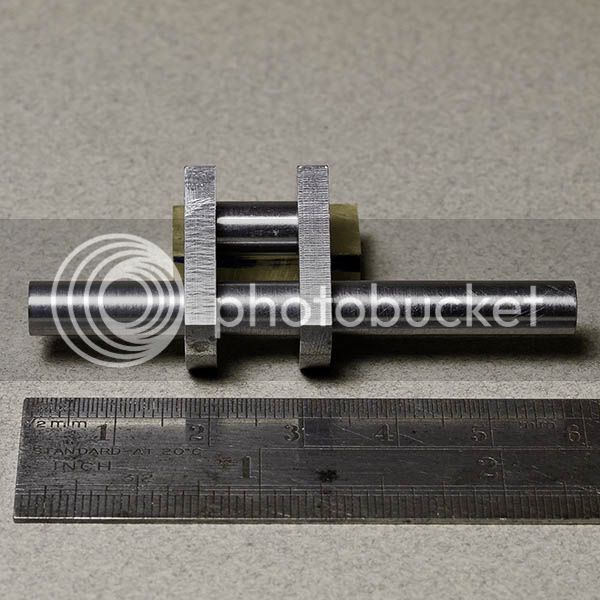

Long way to go yet Vince but some significant parts completed.

Fred, if you go to the first page of the build there is a 3D model of the engine, which is done in Inventor, but I also have a full set of drawings to work from.

Jan

Fred, if you go to the first page of the build there is a 3D model of the engine, which is done in Inventor, but I also have a full set of drawings to work from.

Jan