kutzdibutz

Well-Known Member

- Joined

- Feb 16, 2012

- Messages

- 74

- Reaction score

- 28

Hey there,

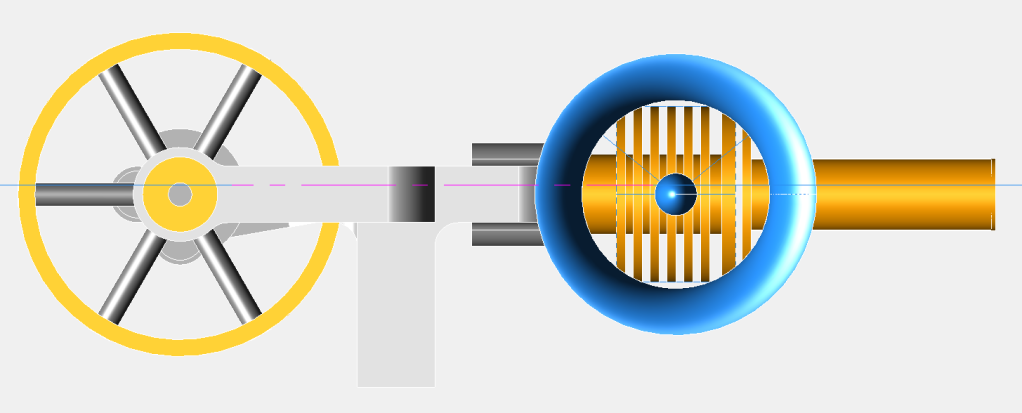

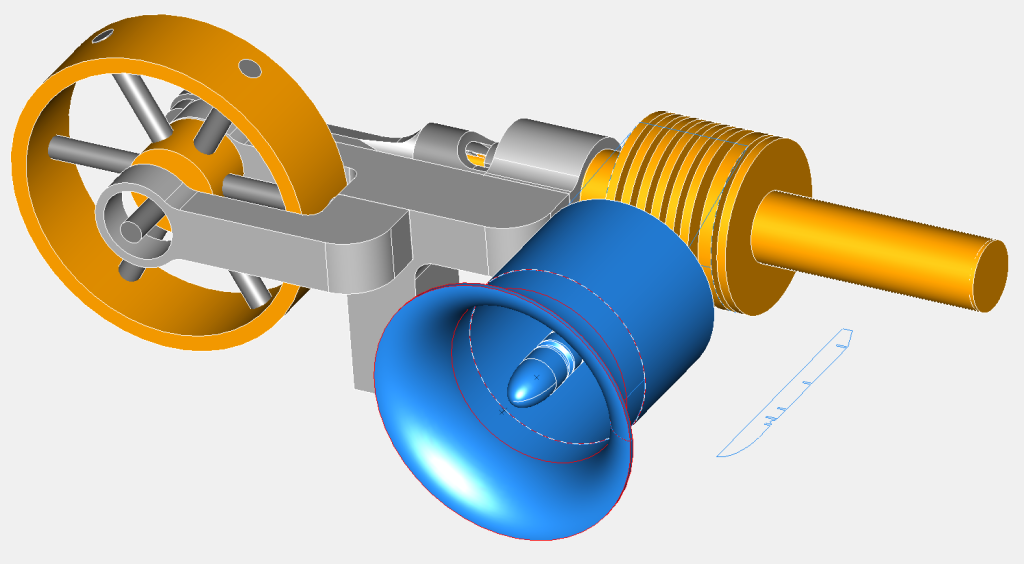

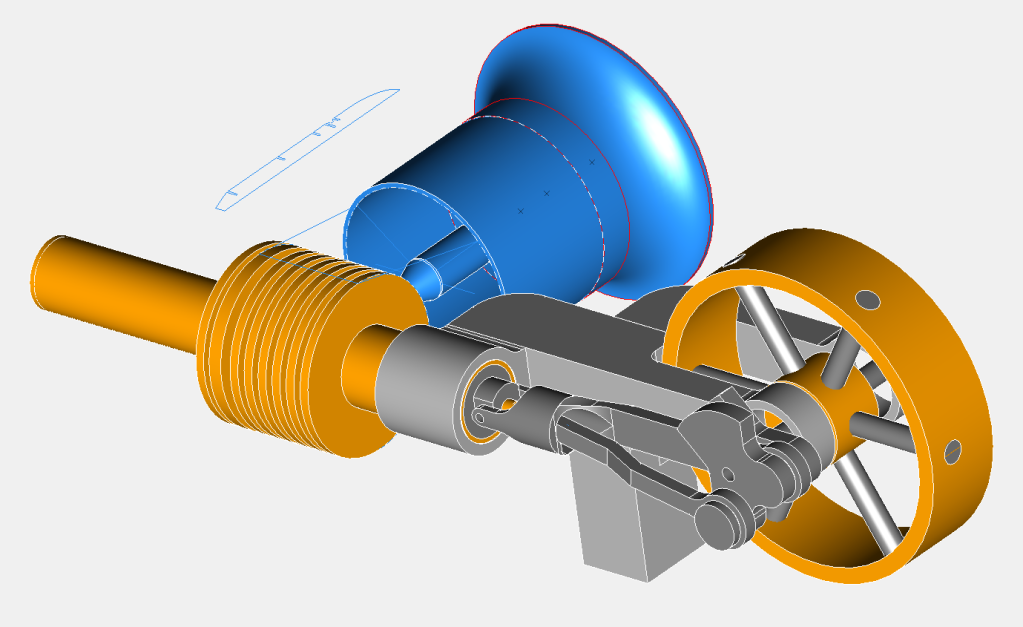

couldnt resist to assemble in between and fire it up...

And it runs- not that big surprise since I re-used most of the running parts, but its still nice to see. At the end I'm quite happy with the balancing, as well with the dynamic balancing...

The little dinging happens when the displacer hits the end of the firetube. So there will be a little bit more room with the stainless steel firetube I'm on.

(sorry for the crappy video- one more hand would be helpful...)

http://s1056.photobucket.com/albums/t370/kutzdibutz/stirling/?action=view¤t=IMG_1311.mp4

http://s1056.photobucket.com/albums/t370/kutzdibutz/stirling/?action=view¤t=IMG_1311.mp4

Cheers, Karsten

couldnt resist to assemble in between and fire it up...

And it runs- not that big surprise since I re-used most of the running parts, but its still nice to see. At the end I'm quite happy with the balancing, as well with the dynamic balancing...

The little dinging happens when the displacer hits the end of the firetube. So there will be a little bit more room with the stainless steel firetube I'm on.

(sorry for the crappy video- one more hand would be helpful...)

Cheers, Karsten