- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Hi Y'all

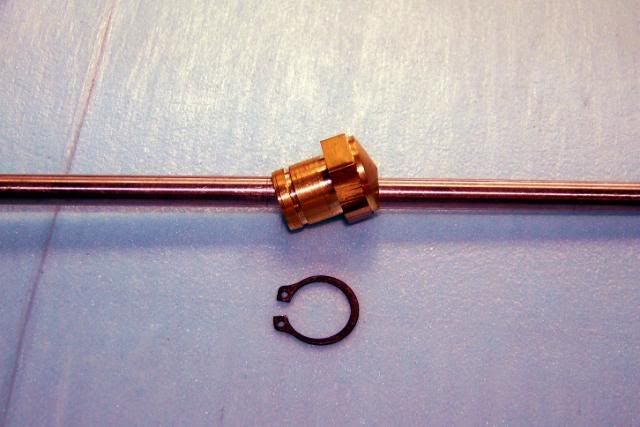

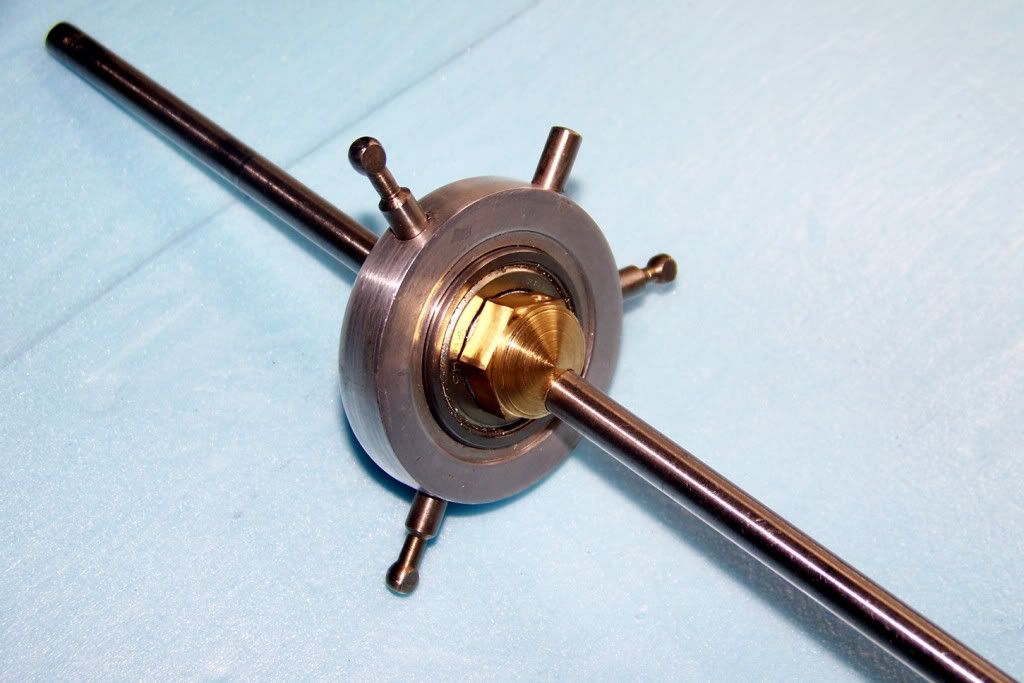

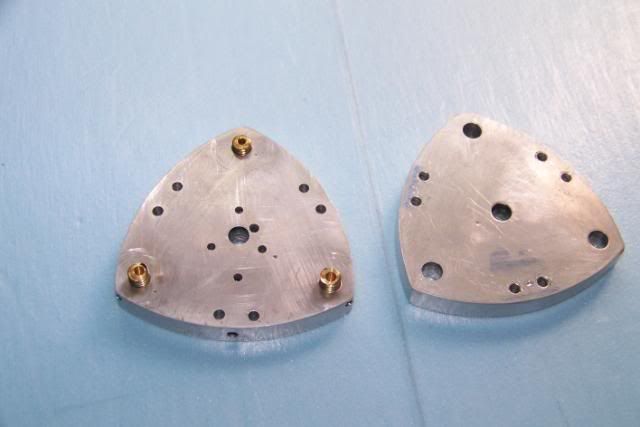

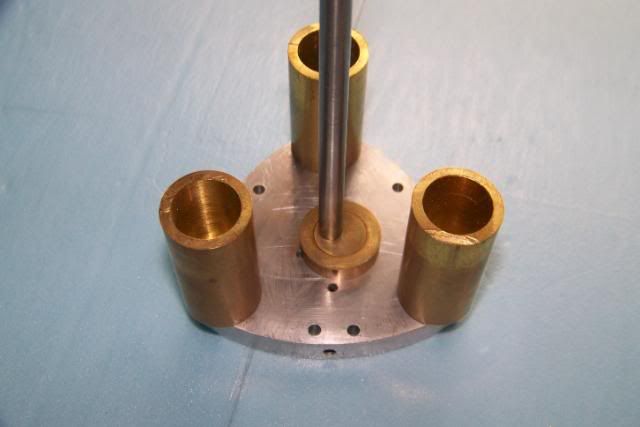

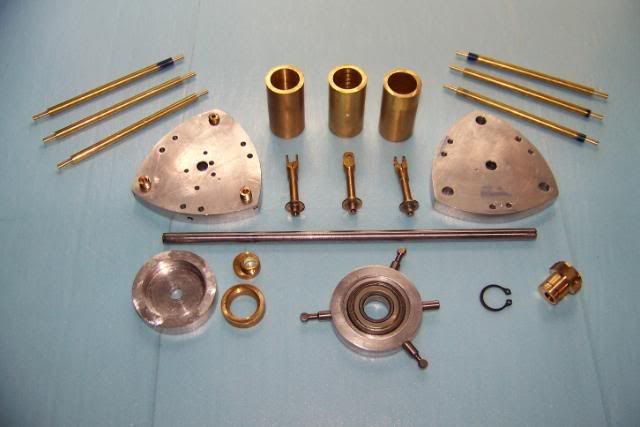

This is going to be my next engine build. It bears a resemblance to the Weeble engine but rather than using a wobble plate to translate axial motion to rotary motion, it uses a Swash Plate mechanism. The swash plate is commercial 1/2" bore ball bearing mounted at an angle to the output shaft. The piston rods (arms) are seated on the outer race and the inner race is mounted on a brass core that is set at a 20 degree angle to the output shaft. The rotary slide valve owes it's design concept to the valve in Elmer's 3 cylinder radial but has been redesigned to allow a double ended shaft. It also eliminates the extremely small diameter drive pin in favor of a normal size eccentric.

It is also slightly larger than the Weeble, with a 5/8" bore and a 29/32" stroke for a 3.1 cu.in

displacement.

Please excuse the bad math. The displacement should be .834 cu.in. (I used diameter instead of radius in the above figure).

Here it is as an Alibre Model in motion.

http://screencast.com/t/h5nnVb1K

Jerry

This is going to be my next engine build. It bears a resemblance to the Weeble engine but rather than using a wobble plate to translate axial motion to rotary motion, it uses a Swash Plate mechanism. The swash plate is commercial 1/2" bore ball bearing mounted at an angle to the output shaft. The piston rods (arms) are seated on the outer race and the inner race is mounted on a brass core that is set at a 20 degree angle to the output shaft. The rotary slide valve owes it's design concept to the valve in Elmer's 3 cylinder radial but has been redesigned to allow a double ended shaft. It also eliminates the extremely small diameter drive pin in favor of a normal size eccentric.

It is also slightly larger than the Weeble, with a 5/8" bore and a 29/32" stroke for a 3.1 cu.in

displacement.

Please excuse the bad math. The displacement should be .834 cu.in. (I used diameter instead of radius in the above figure).

Here it is as an Alibre Model in motion.

http://screencast.com/t/h5nnVb1K

Jerry