Her we are again as happy as can be etc etc:-----

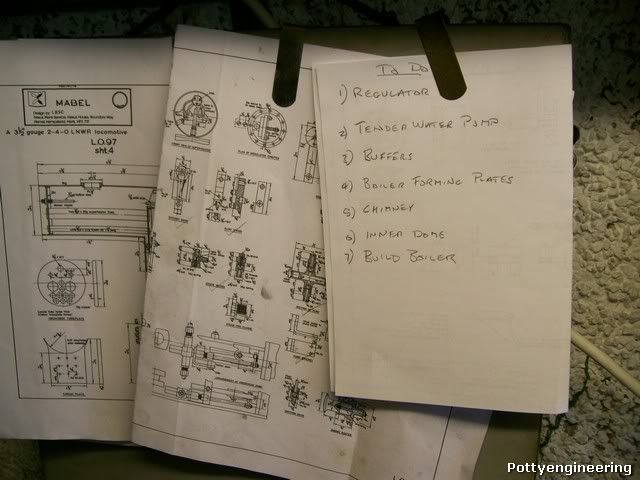

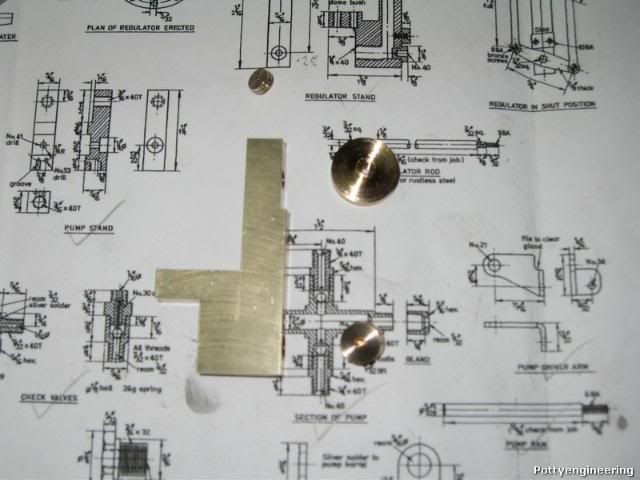

I thought I'd make a start on the lubricator for my loco.

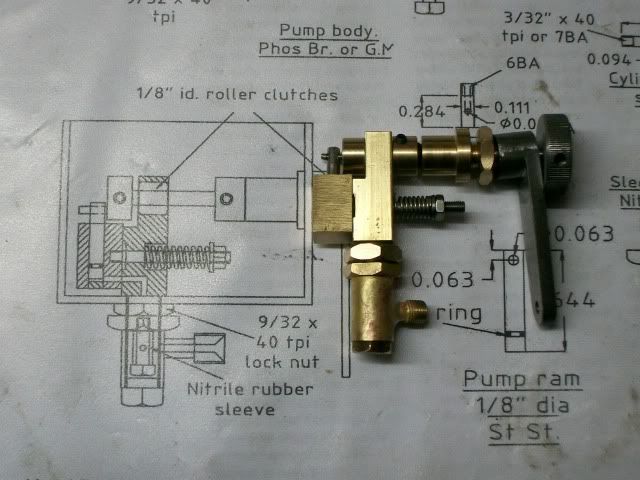

The design as drawn is a ratchet driven osilator pump similar to the little engines we make but instead of driving its driven, so you can use it to pump. I'm going to follow a design recently posted in Model Engineer (22nd May 2009) that uses a much more efficient friction clutch instead of a ratchet and instead of having sprung balls for the none return valve uses a Nitrile rubber valve like the bicycle valves.

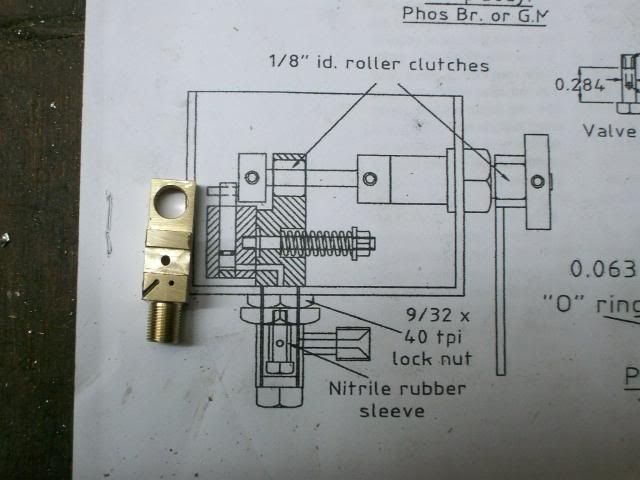

The first bit I made was the stand.

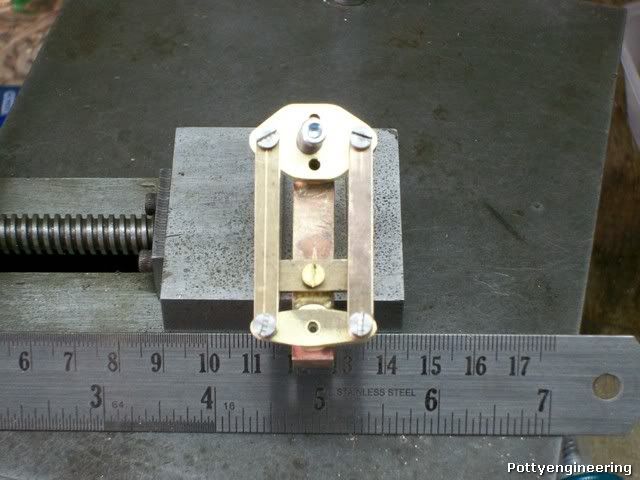

The diagonal groove is where the oil is sucked up into the piston, it then swings over and pump out the other hole on the return stroke.

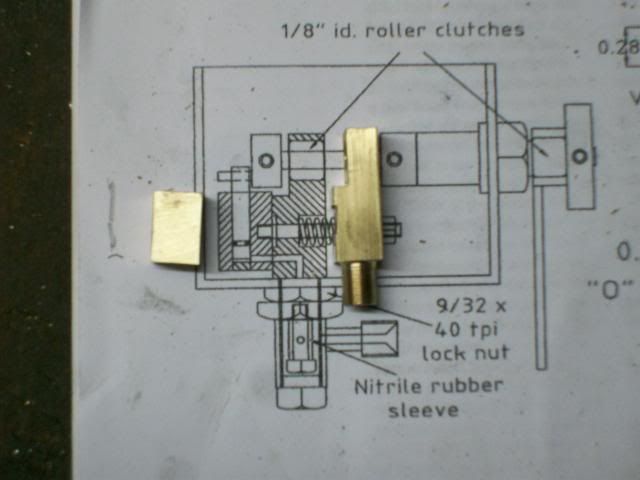

Next bit to be made the piston.

I wasn't too happy with the O ring on the piston, I'd seen another build where the chap had fitted a small stuffing box on the cylinder, so I re-made the cylinder to this design and used PTFE tape to stuff the gland, it seems to work Ok, so this is it all together.

Fabricated an oil tank up, my first attemp from copper was a disaster I think the copper was too thick to get nice neat bends, so re-made out of some nice thin brass I had, this is the lubricator squeezed into the the tank.

Tried it out under drill power I won't run it under loco power with the ratchets until I've completed the water pump then I'll strip everything down and fit both at the same time. This is it running.

[ame]http://www.youtube.com/watch?v=9bVT-Xk5m1s[/ame]

:big: :big: :big: :big: :big: :big:

Have fun

Stew