GWRdriver

Senior Member

- Joined

- Jan 22, 2009

- Messages

- 721

- Reaction score

- 109

Stew,

Very clever, very nicely done. I'm always interested to see what dodges folks use to get an awkward job done.

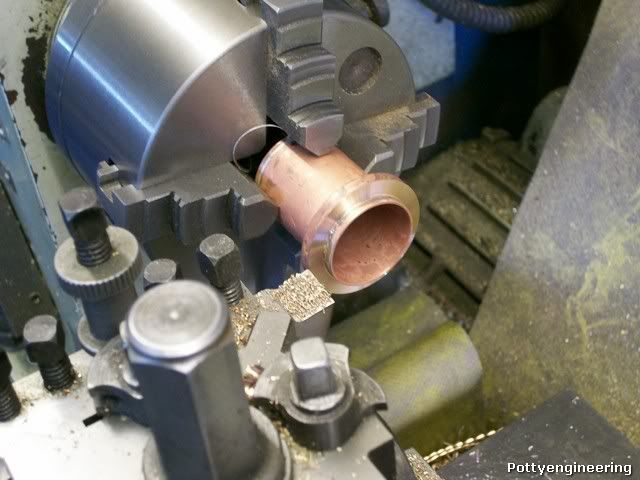

For me an awkward job is, among other things, one which the shape and material present holding challenges which if not done securely could be potentially fatal to the part. Brass and bronze are especially difficult due to the tendency of tools to snag and dig in, thus the need for very secure holding . . . without damaging or crushing the part of course!

I'll have exactly the same job to do for my loco this summer and your collet technique bears remembering, especially for flycutting the base.

Very clever, very nicely done. I'm always interested to see what dodges folks use to get an awkward job done.

For me an awkward job is, among other things, one which the shape and material present holding challenges which if not done securely could be potentially fatal to the part. Brass and bronze are especially difficult due to the tendency of tools to snag and dig in, thus the need for very secure holding . . . without damaging or crushing the part of course!

I'll have exactly the same job to do for my loco this summer and your collet technique bears remembering, especially for flycutting the base.