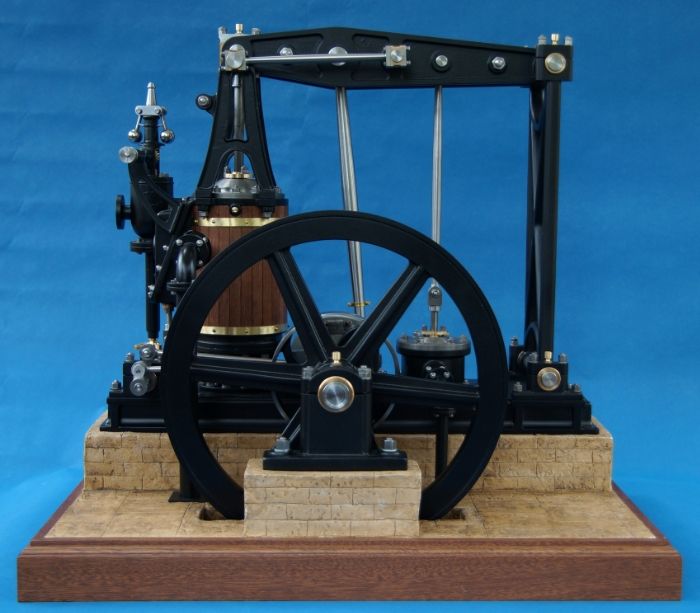

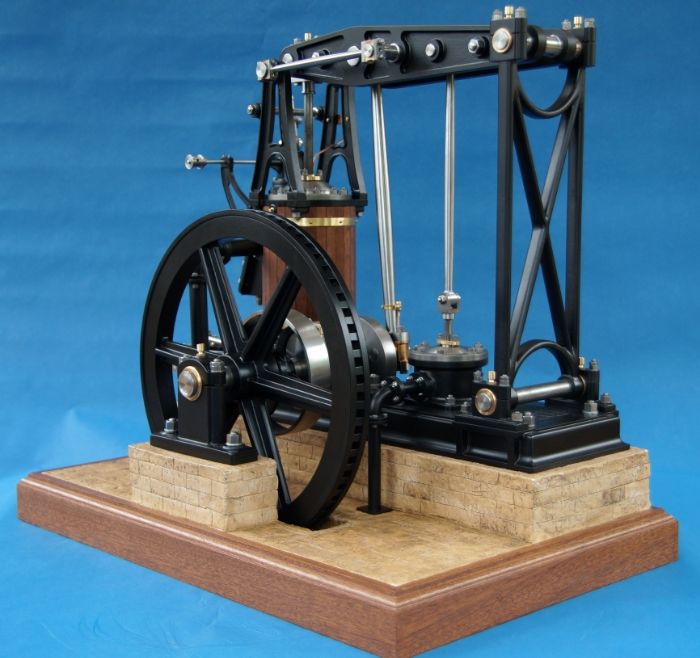

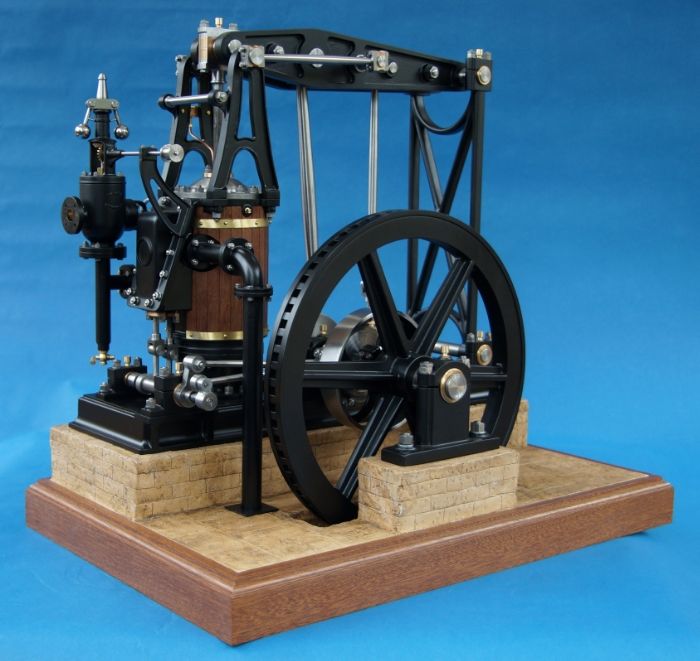

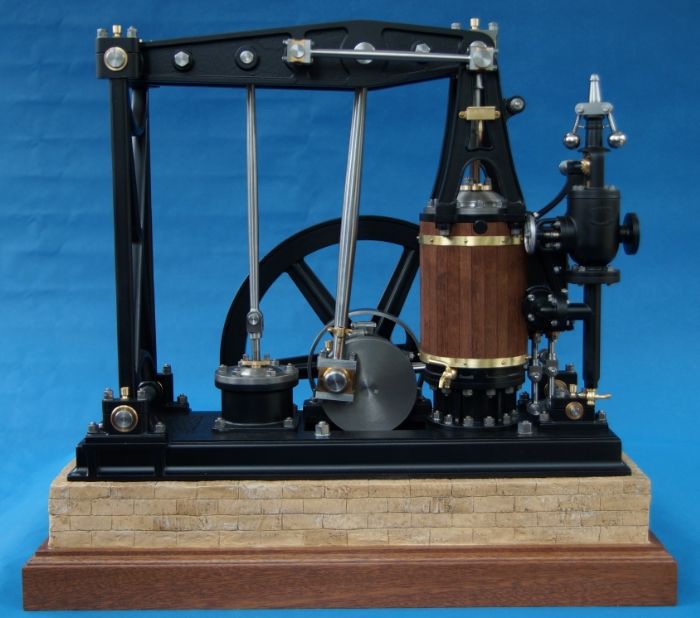

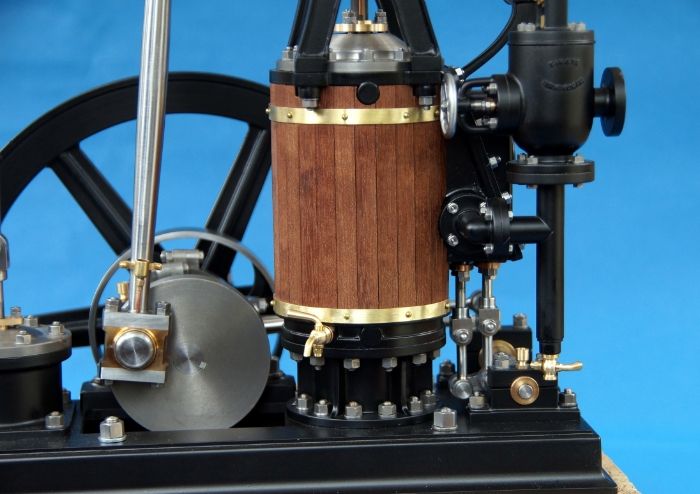

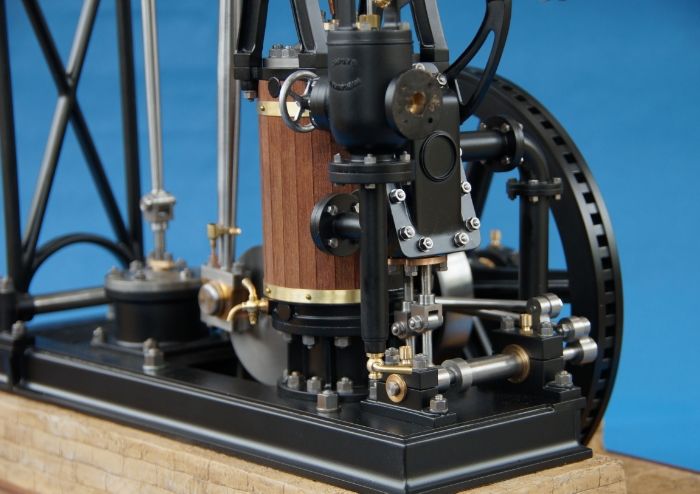

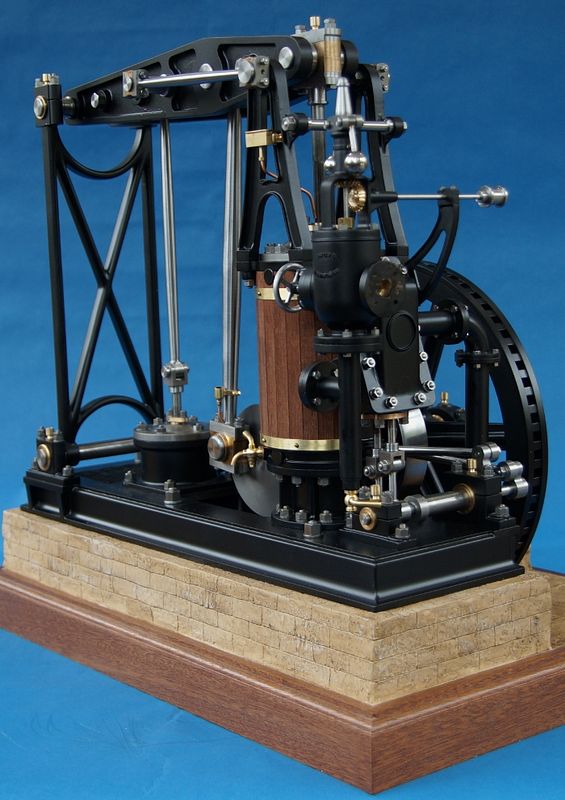

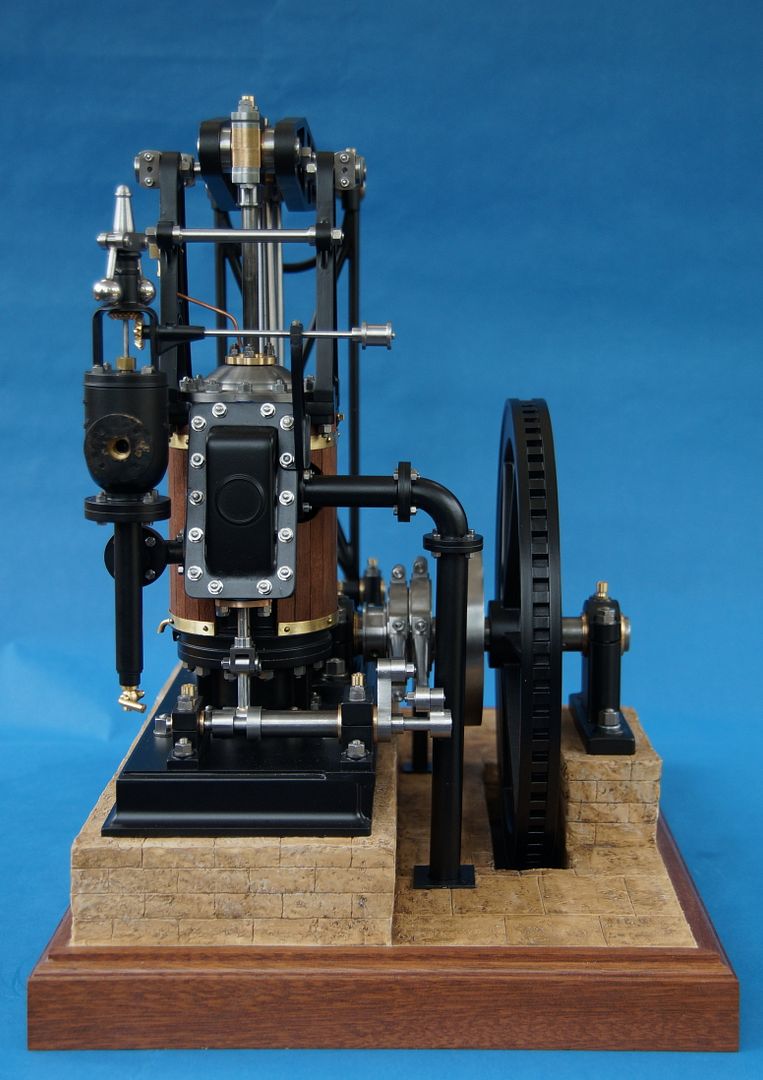

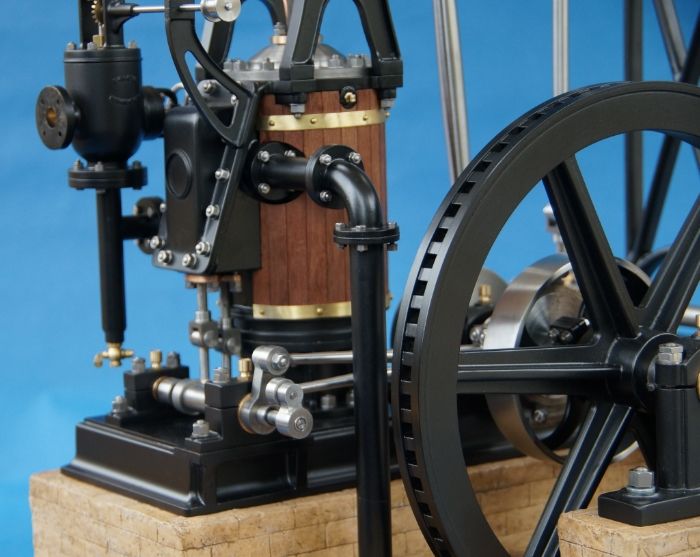

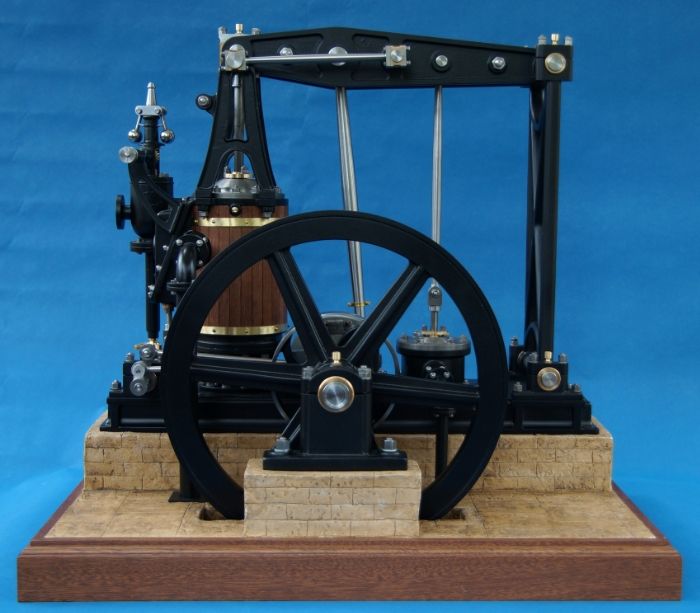

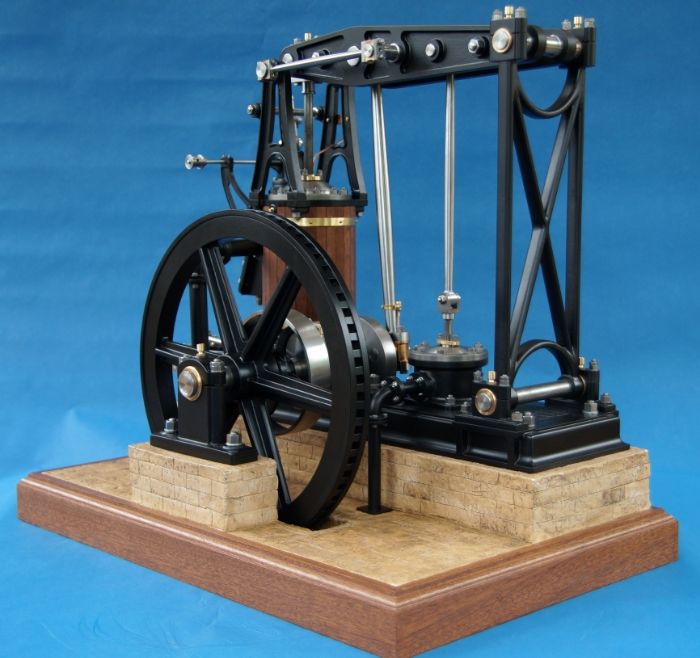

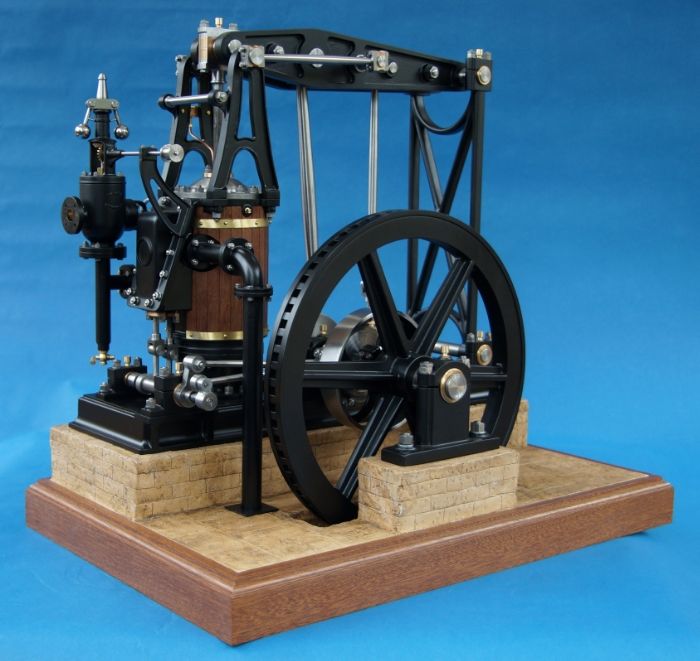

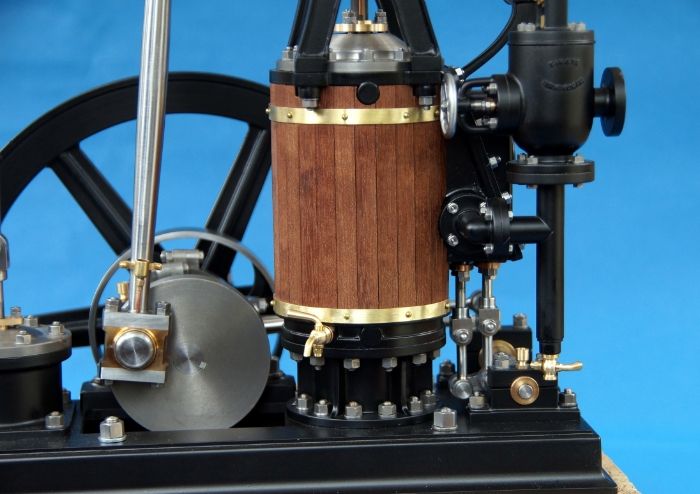

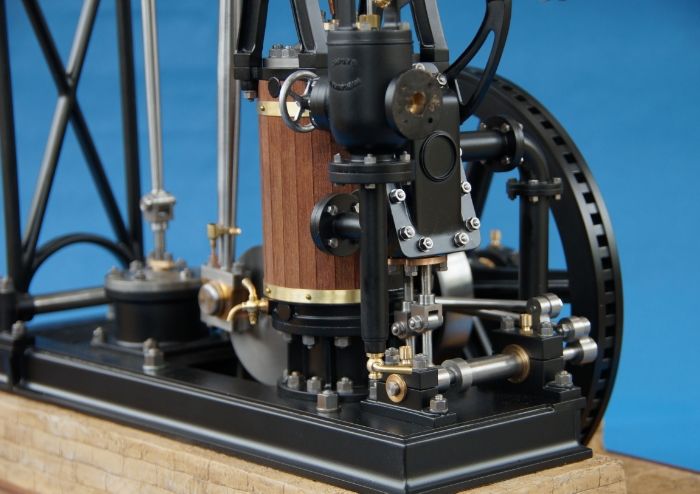

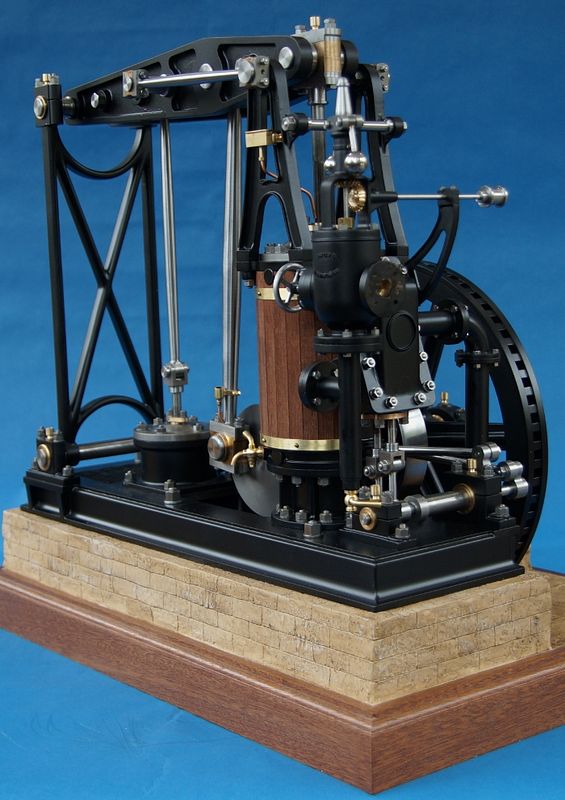

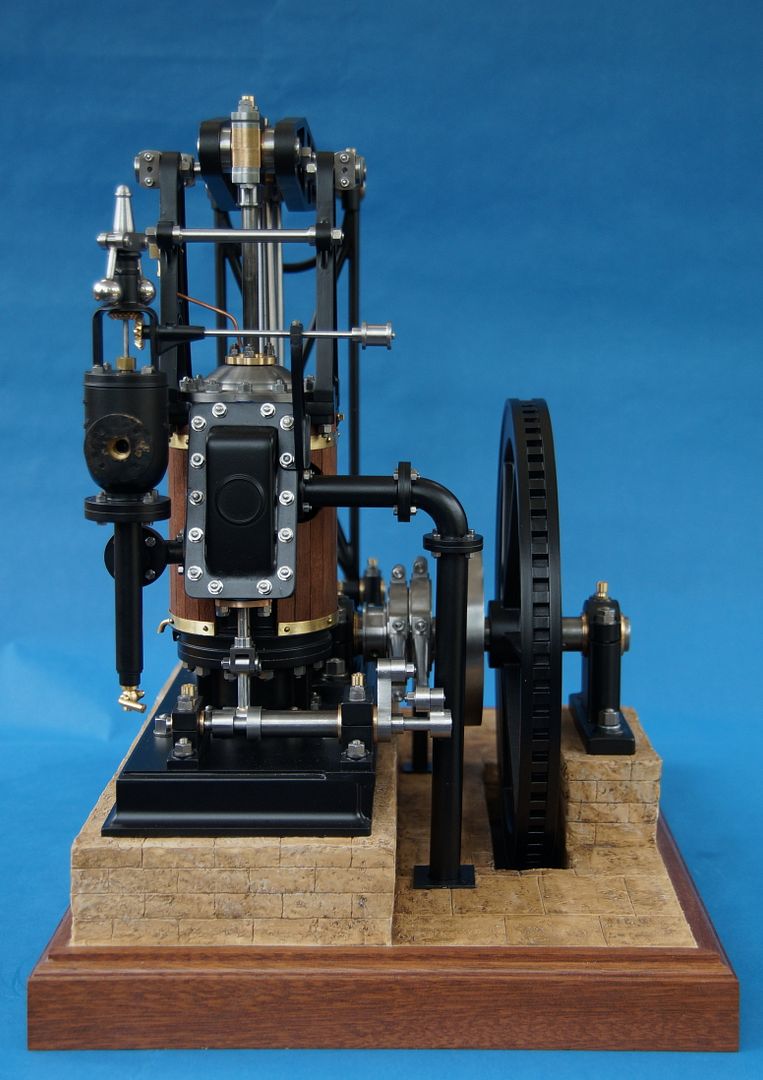

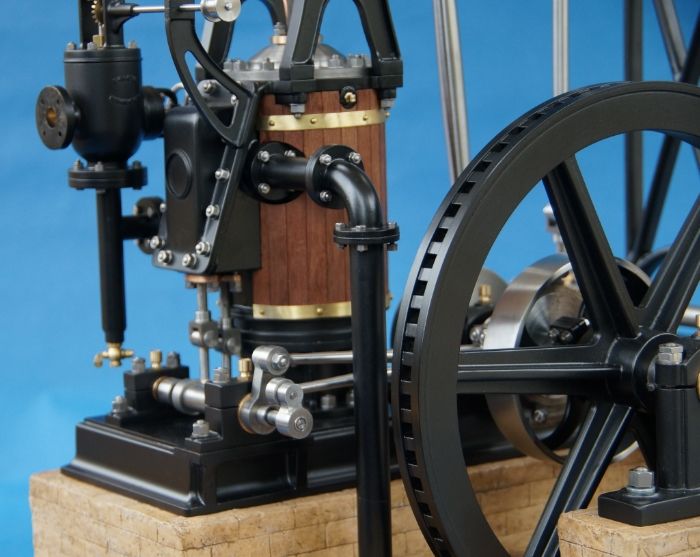

Well I remembered how it all went back together so this is it just about done and dusted, there is still a belt for the governor and a makers plate to do. Full details of the build are here

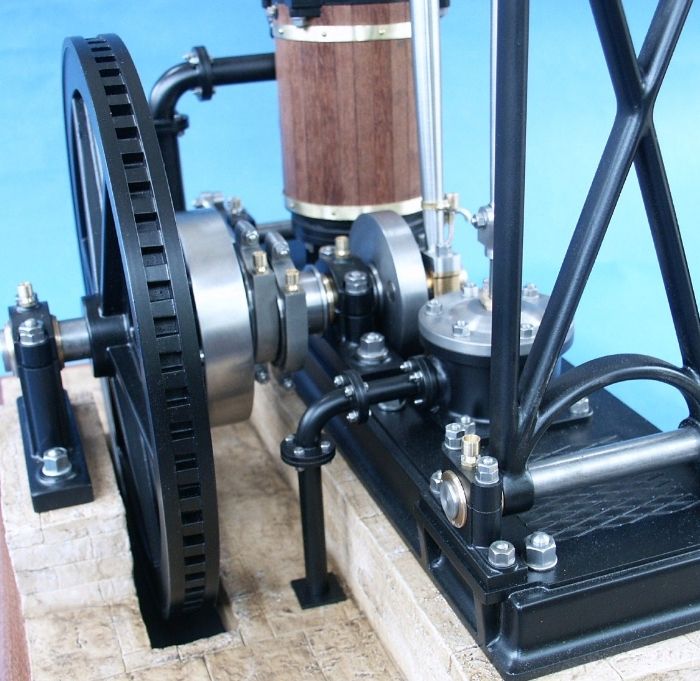

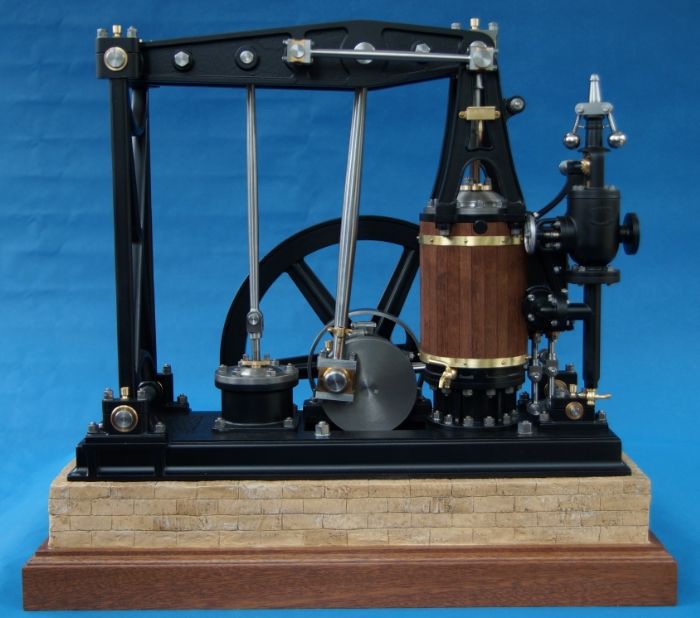

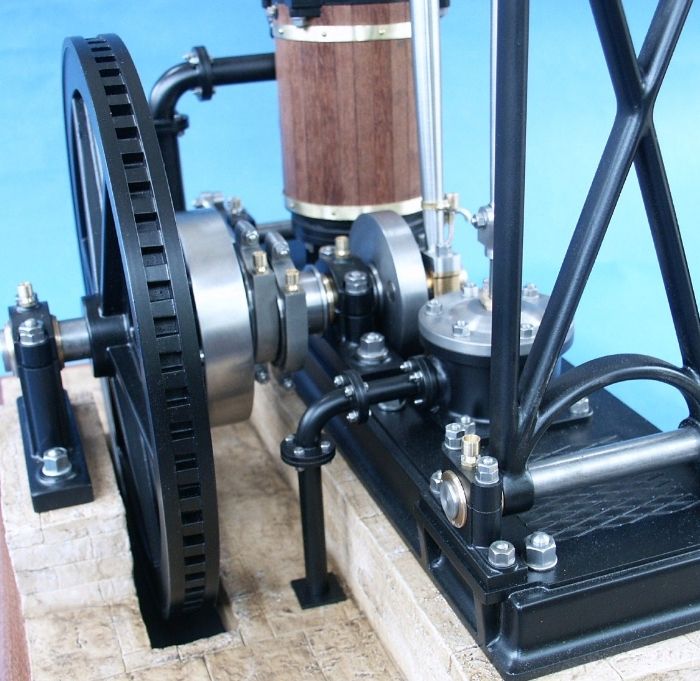

And the usual Coke can shot so you can get an idea of size

And finally a short video, the compressor was having a job to keep up thats why it starts off a bit fast for my liking and then dies out.

[ame]http://youtu.be/jDhF7zYsK1o[/ame]

J

And the usual Coke can shot so you can get an idea of size

And finally a short video, the compressor was having a job to keep up thats why it starts off a bit fast for my liking and then dies out.

[ame]http://youtu.be/jDhF7zYsK1o[/ame]

J