Thanks everyone for the comments. Every day on this earth should be a learning day and I'll be one of the first to stand in line for an education.

At this point I guess I should 'come clean'. The orginal plan for building these engines was to make a machined engine for the buyer who didn't have the tools to do it. The buyer would then do the fine tuning, adjusting, cleanup, paint and polishing.

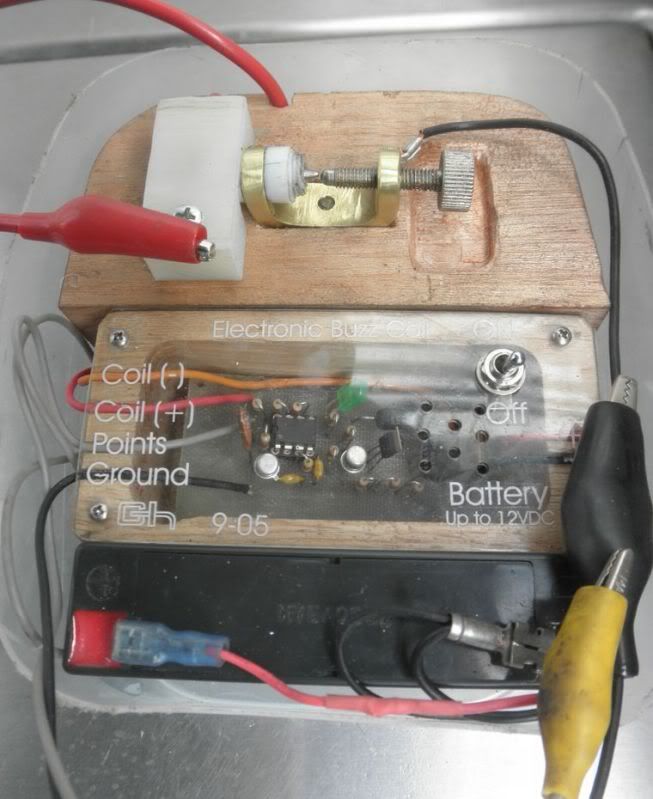

When I finished this engine for the fellows at Ministeam I was asked if I couldn't then get it running. I told them I could but that would add more time to the build and I didn't have a buzz coil or ignition setup for the igniter.

They made arrangements with Roy Sholl from S&S (ignition systems) to take over the engine so he could develop his ignition for the igniter. He would also make up a plug for the igniter cavity that would be tapped for a spark plug. Along with this he would come up with a discreet system for triggering the spark plug, (Hall effect or whatever). This way the builder who couldn't work with real tiny parts could skip the igniter and use a spark plug. Roy is going to document his work and I will then put it on the revised drawings.

Before Roy was given the engine I checked and double checked everything to make sure he wouldn't have problems with the mechanical parts, fit and finish, valve and ignition timing etc.

He started playing with the engine and could get it to fire now and then but not run consistently. This was also somewhat of a learning process for him with this type of engine. We talked back and forth to try to resolve some of the issues he was having. He said that it seemed like the valve in the carb wasn't holding the compression very well. I explained to him that it wasn't supposed to, with the intake valve closed there shouldn't be any pressure at the carb. At this point he said he didn't see an intake valve.

When I first saw the Galloways, kits and pictures I thought the same thing. Where the heck is the intake valve. Well it's actually underneath the rocker pedestal for the exhaust valve. It's a hollow cylinder with the pivot for the exhaust rocker at the top.

While he was trying to work the bugs out of the engine I told him that I would post on the model forums and see if I could get some help. Roy doesn't frequent these sites much. Rather than go through this long winded explanation I just though it would be easier to say that 'I' was having problems.

I got an email from Roy this evening and he said he finally got the engine running for several 3 minute stints. When he said the valve in the carb wasn't holding compression it seems like the intake valve had gotten a small piece of gunk under the seat and was allowing the compression pressure to go all the way back to the carb. He cleaned the valve and he said the engine compression was tremendous as it had been when I checked everything out. The problem he was having now is that the needle valve is so sensitive that about 1/16 turn will go from running to rich.

As some of you have stated the needle probably needs to have a much longer taper to it. I hate to keep harping on it but you would think the original builders would have documented this.

I'm sorry for the deceit but I just thought it easier to ask the questions myself. I will keep everyone up to date on Roy's findings so that anyone building one of these will have the best information available to them.

Thanks a bunch for all the thoughts and ideas.

George