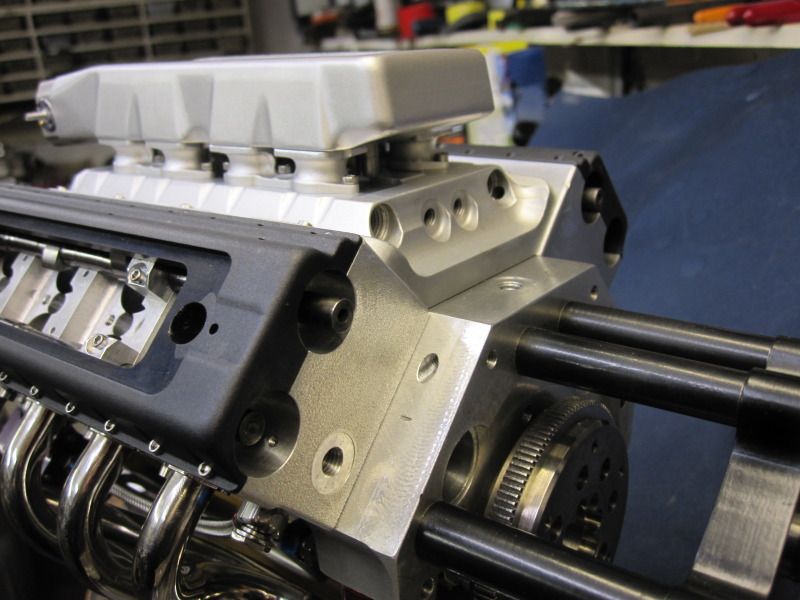

Longrat, I wouldn't place too much emphasis on the nitric acid stage. I only did it with the cam covers as there was too much work gone into them to balls it up at the last moment, and as I'd used the steel shot to peen them.

We shot peen a lot of titanium at work, and most of these components get a nitric acid dip afterwards, or a glass bead decontamination.

I didn't want to use the glass afterwards as it makes the surface too porous for anodising, hence the steel shot stage, to 'seal' the surface.

It makes for a super finish after dying, but it shows fingermarks up something terrible, and is therefore unpractical for an engine.

Most of the other anodised bits on the engine haven't had the acid dip, or the caustic soda for that matter. I mostly degrease with washing up liquid, and then straight into the anodising tank.

My only tip would be once the part has gone into the anodising tank, don't let it ever dry out until you've finished the hot water sealing step

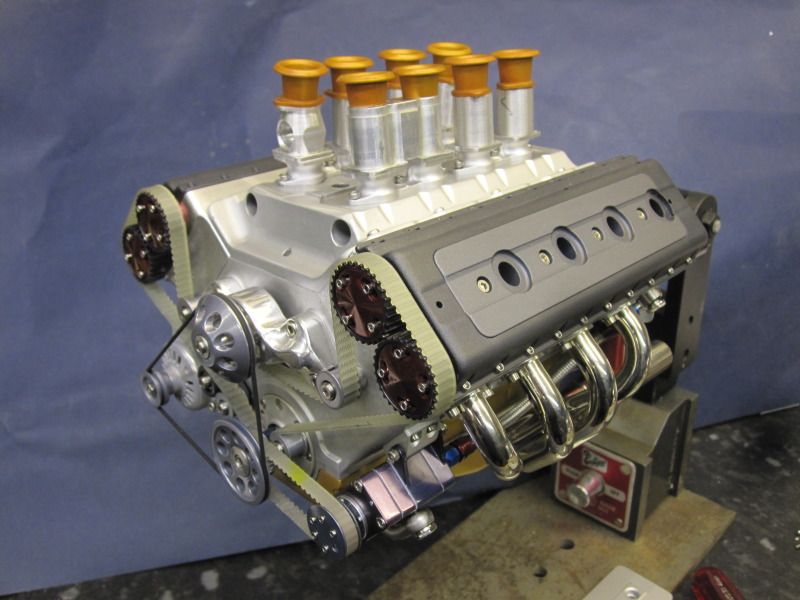

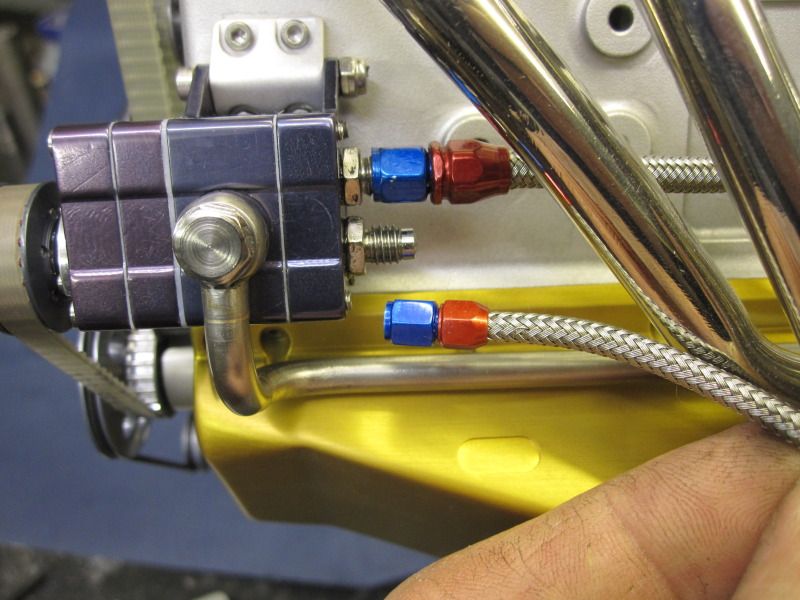

Mark, I haven't thought too much yet about the injector control. I am familiar with setting up stand alone injection ecu's and when I get that far, if I haven't had a brainwave I'll just buy a Megasquirt or similar and control it with that. I'll use a Map sensor, in case I get bored in the future and supercharge it, but won't bother with o2 sensor