Andrew Pullin

Member

Hi Guys,

I am a bit new at this so please bear with me.

I am a Mature Age Engineering Student studying Trade Engineering. I am currently creating a set of

Drawings of Gerry's Beam Engine in Metric based upon the Metric Plans that Ken I drew up on one

very large sheet and posted on this site. The reason I am doing this is so that I have a set of smaller

A3 and A4 sheets that are a bit more manageable in the School Workshop and my intention is to build

this engine as a School Project.

Since I am new at Engineering there are many things I have to learn. I am really enjoying my Technical

Drawing and I taught myself CAD. What I need to get my head around is the Australian Standards we

use for Engineering Drawing, so as I transcribe Ken I's plans I am trying to follow AS 1100.201, which is

the Mechanical Engineering version of the Standard.

The process is going great so far but there is one thing I have noticed that is missing from Ken I's plans

which is probably very obvious to Ken I and some of you more experienced people, but is not very

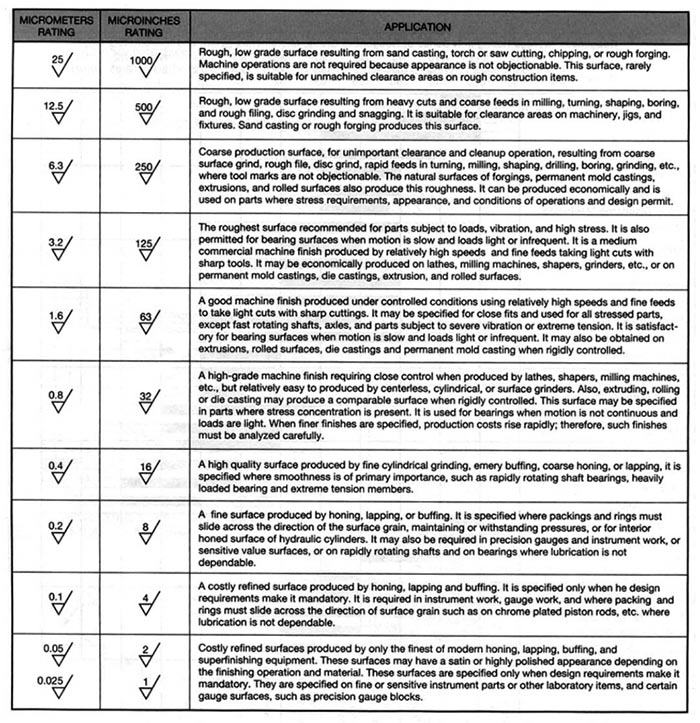

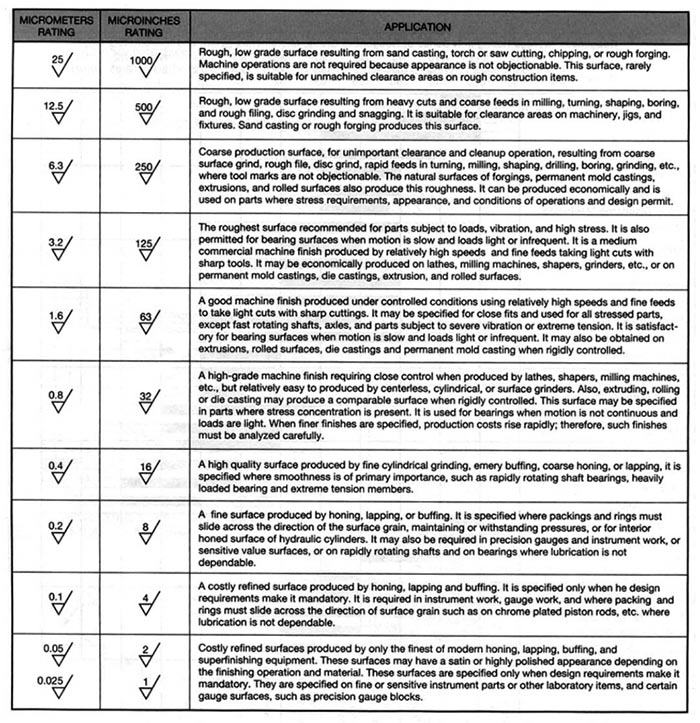

obvious to me and that is the Surface Finish of each of the parts. At the moment I am aware that there

are different finishes when creating parts but I have not actually used them yet. I found this chart:

at https://www.cnccookbook.com/surface-finish-chart-symbols-measure-calculators/

and the Australian Standard includes the Finish on a typical Detail Drawing. Since one of the

reasons I am doing this exercise is to try to learn the Standards and practice my CAD, I would

like to include the Finish on my transcribed Drawings but I don't actually know which ones are

appropriate or would be suitable for this particular Project.

So after all of that explanation, my question basically comes to this:

Could someone please have a look at Ken I's plans and give me some advice on what I SHOULD

be doing in terms of Finish?

I have looked at Brian's Beam Engine by Brian Rupnow which is a similar engine, and his finishes

all appear to be 63 microinches, which is the Metric Equivalent of 1.6 according to the above Chart.

Would this be suitable? Is it the same for ALL the Parts?

The Plan is to end up with a nice looking Model to display (my wife would call it a Dust Collector),

so the Finish I am looking for would be something resembling the Machine from the early 1800s

that it is a Model of.

Your help and guidance would be most appreciated.

Thanks in Advance.

Andrew

I am a bit new at this so please bear with me.

I am a Mature Age Engineering Student studying Trade Engineering. I am currently creating a set of

Drawings of Gerry's Beam Engine in Metric based upon the Metric Plans that Ken I drew up on one

very large sheet and posted on this site. The reason I am doing this is so that I have a set of smaller

A3 and A4 sheets that are a bit more manageable in the School Workshop and my intention is to build

this engine as a School Project.

Since I am new at Engineering there are many things I have to learn. I am really enjoying my Technical

Drawing and I taught myself CAD. What I need to get my head around is the Australian Standards we

use for Engineering Drawing, so as I transcribe Ken I's plans I am trying to follow AS 1100.201, which is

the Mechanical Engineering version of the Standard.

The process is going great so far but there is one thing I have noticed that is missing from Ken I's plans

which is probably very obvious to Ken I and some of you more experienced people, but is not very

obvious to me and that is the Surface Finish of each of the parts. At the moment I am aware that there

are different finishes when creating parts but I have not actually used them yet. I found this chart:

at https://www.cnccookbook.com/surface-finish-chart-symbols-measure-calculators/

and the Australian Standard includes the Finish on a typical Detail Drawing. Since one of the

reasons I am doing this exercise is to try to learn the Standards and practice my CAD, I would

like to include the Finish on my transcribed Drawings but I don't actually know which ones are

appropriate or would be suitable for this particular Project.

So after all of that explanation, my question basically comes to this:

Could someone please have a look at Ken I's plans and give me some advice on what I SHOULD

be doing in terms of Finish?

I have looked at Brian's Beam Engine by Brian Rupnow which is a similar engine, and his finishes

all appear to be 63 microinches, which is the Metric Equivalent of 1.6 according to the above Chart.

Would this be suitable? Is it the same for ALL the Parts?

The Plan is to end up with a nice looking Model to display (my wife would call it a Dust Collector),

so the Finish I am looking for would be something resembling the Machine from the early 1800s

that it is a Model of.

Your help and guidance would be most appreciated.

Thanks in Advance.

Andrew