This has been quite a hiatus. Almost a year.

Time really flies when your having fun. When I get stumped I usually stop work and try to figure things out. But nothing was coming to mind and I got distracted by summer. So I just let summer happen, and the Wyvernish project came to an abrupt halt.

My apologies if I left anybody hanging.

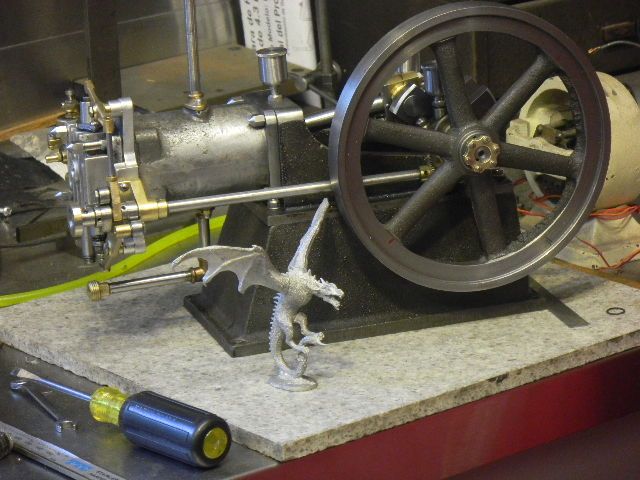

I took my models and a few antique engines along with me as my wife and I wandered around the state visiting our usual antique engine shows. Campfires and good friends, add some cold beer.. Life was good.

Then as all good things seem to do, summer ended, which for me encompasses May thru October.

Back to the doldrums of winter weather. It's not all bad, there's nothing quite as beautiful as a fresh snowfall, before you realize you have to deal with the reality of going out in the cold and dealing with the mess Ma Nature dumped on your doorstep.

Then the heating bills start coming, more snow then severe cold, and the sound of the furnace cycling is enough to cause sever depression.

So now spring is trying to arrive and old man winter ain't giving up yet.

We just got another 5" of snow last night.

Thank God for inventing the work shop and nice warm fire in the wood stove. It really helps to keep your sanity in check. So back to work.

Around Christmas I decided to try few fixes on the Wyvern, which ran but not well enough. I brought it out from it's corner and dusted off. I started to make a list of the things that I just didn't think where right.

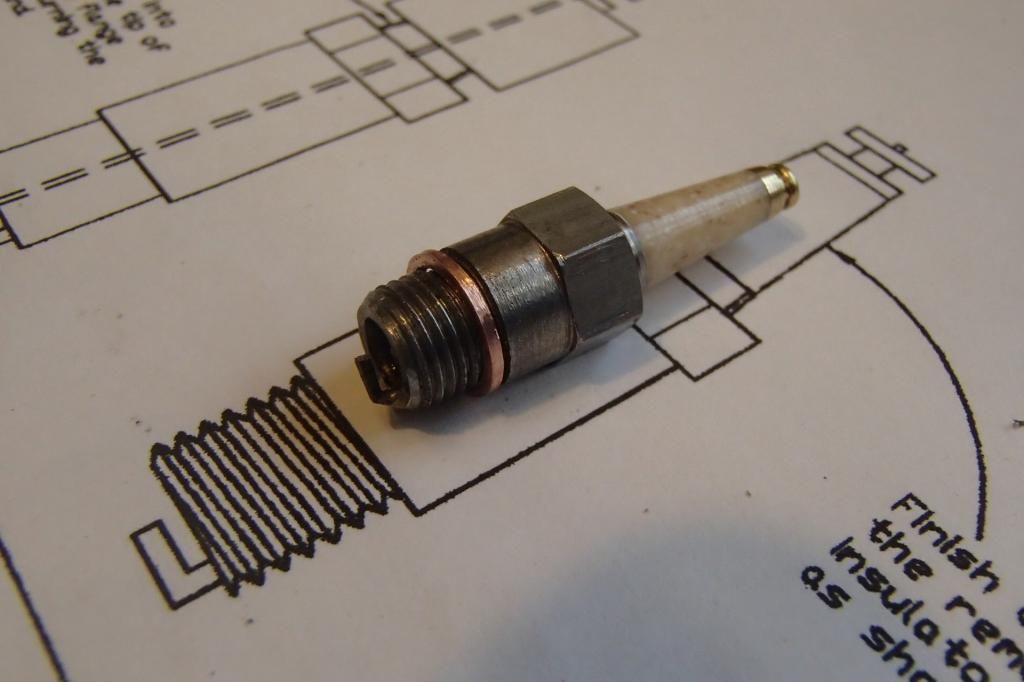

The two piece, tapered thread spark plug I made had a problem, as well as the cams, which due to my amateurish touch, were a tad off center. Maybe causing problems with the timing.

The threaded valve keepers kept loosening and that would also need to be dealt with.

And then the carburetor, which I suspected was the real culprit.

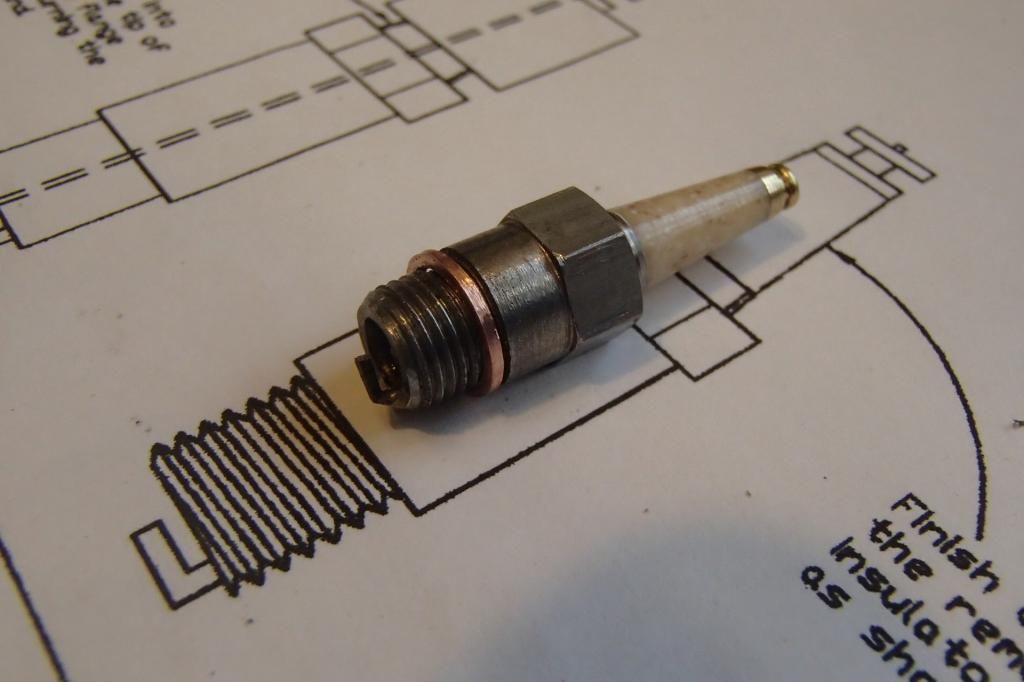

The spark plug was first in line. Ive made a number of plugs at this point and always use George Britnell's method, except for the the two piece. That plug was not the original I used in this engine, but was an after thought, which didn't work out as the end of the plug interfered with the valves. I shortened the end to miss the valves, but it was now seeping.

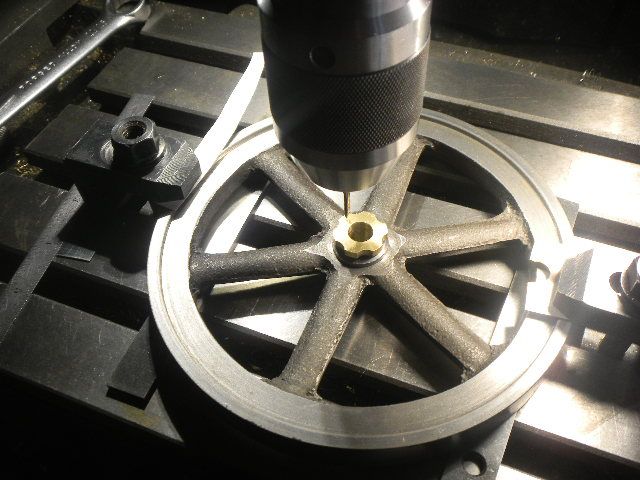

I was thinking I would have to drill and plug the old 1/16 pipe taper I used for the plug, but found that a 5/16-32 straight thread would be just fine, after re-drilling and tapping.

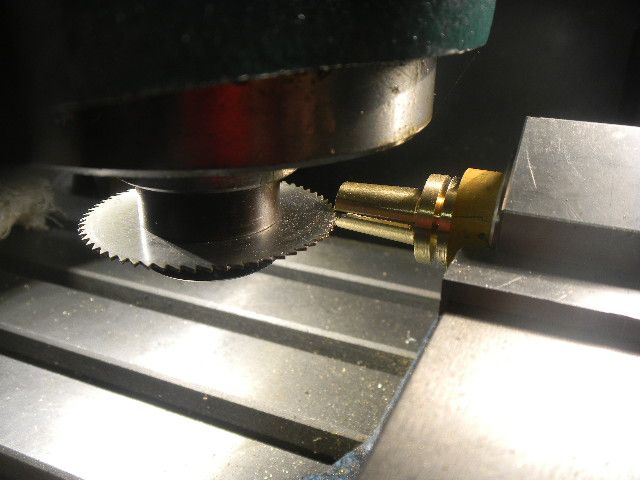

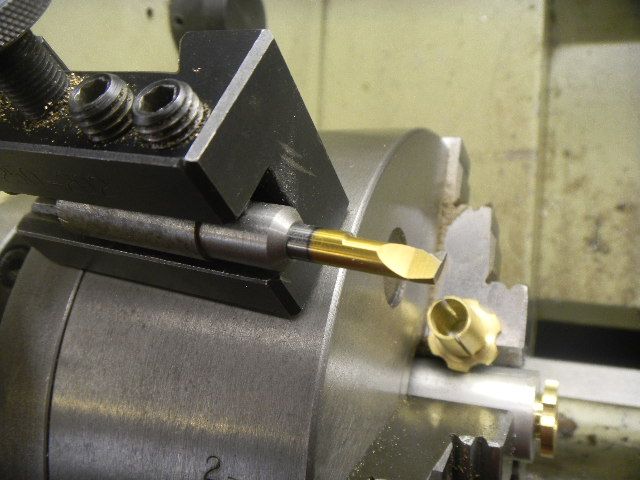

I used the bold look of Corian this time. The Corian is way stiffer and seems to insulate OK. The copper washer was cut from 3/8 tubing on the lathe with a really narrow cutoff tool and using a 5/16 rod for support.

The old cams, I figured out quite a while later, were not centered very well because I used my RT horizontally on my mill. That would have worked out fine, but the column on my mill was not square to the table. The mill tram was fairly acceptable when using the quill only for work, but work pieces would be off center if I centered at one col. height and did the machining at another. I got that straightened out after spending half a day shimming the base of the column. I can finally say my mill is trammed within a couple thou.

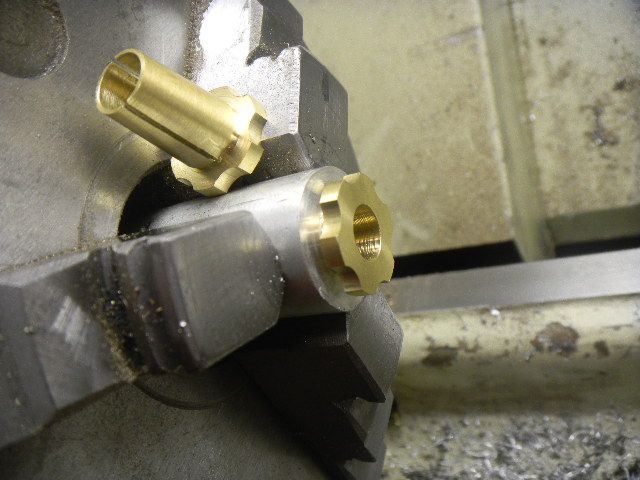

The new cams were made with the RT vertical on the mill.

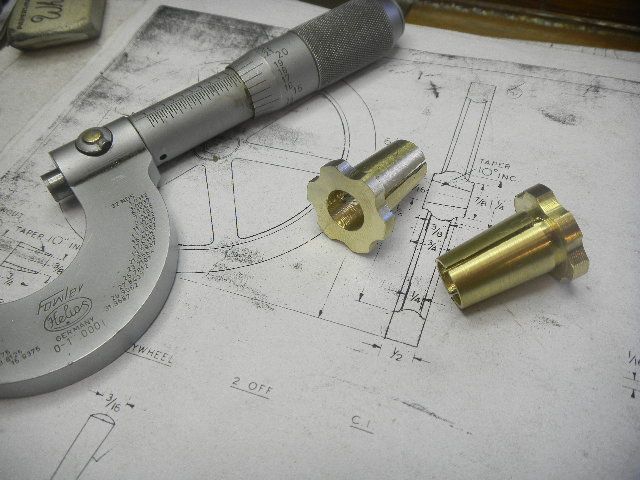

Old and new parts along with a couple of failed lower pieces for the new spark plug.

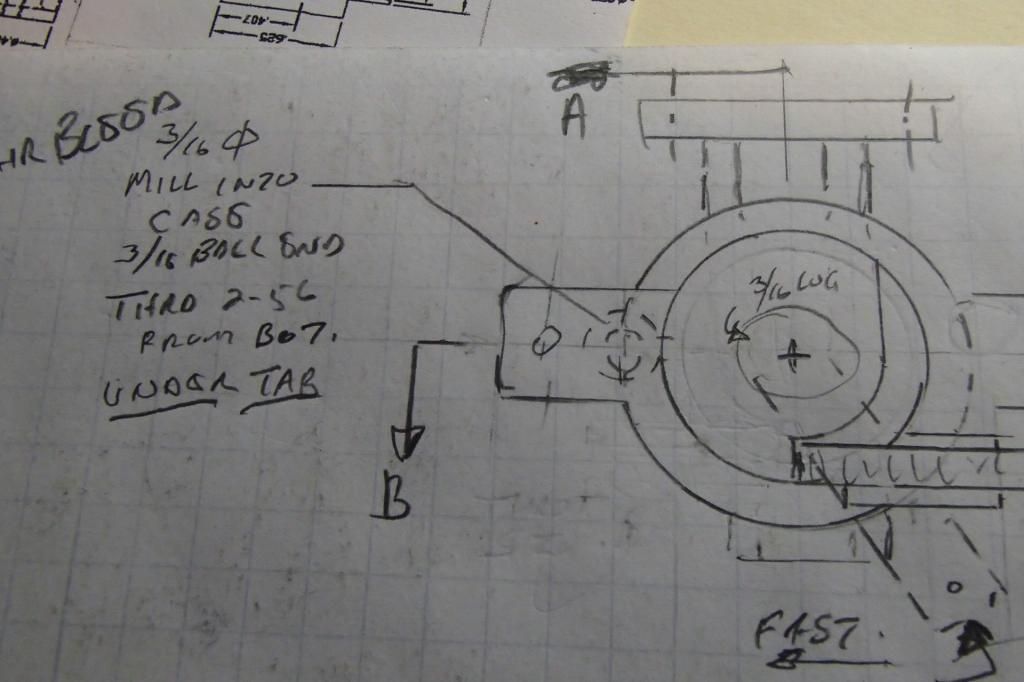

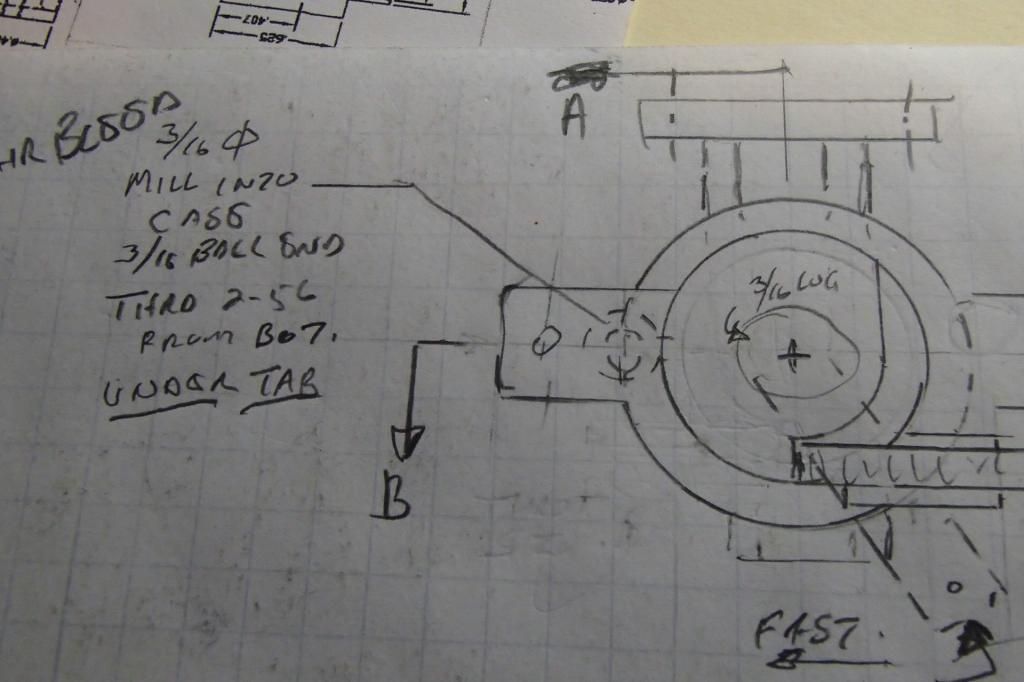

Those easier parts done, now the more difficult carb. I fell back on George Britnell's experience again, using his air bleed carb design. The build would have been much simpler if I used his plan as drawn, but I would complicate that by disguising it to look pretty much like the original Wyvern design.

Again using a silver soldered assembly, but this time using stainless steel in lieu of brass as I did on the first one. The stainless is way less prone to melting at the high temps of soldering, and I prefer the look.

The engine assembled and was trial run. I would like to say it started and ran well. It started easily and ran fairly well, but too fast and was now overheating. I couldn't find the happy spot where it would run at a lower speed. The pot muffler actually charred the new/permanent wooden base it was on.

To make matters worse, the magnet wheel for the Hall ignition worked loose and the engine fired way to early and came to an immediate and damaging halt. It spun one side end of the Loctite and pinned crank shaft.

A cloud of gloom and despair hung over my shop for rest of that day and, again, the Wyvern was vanquished to the far end of my workbench. My enthusiasm was dashed and I just didn't want to look at it for a while.

So of all things, I went and started another engine build, while the poor Wyvern was weeping in the corner, lacking my affection.

More to follow, and finally, a happy ending.