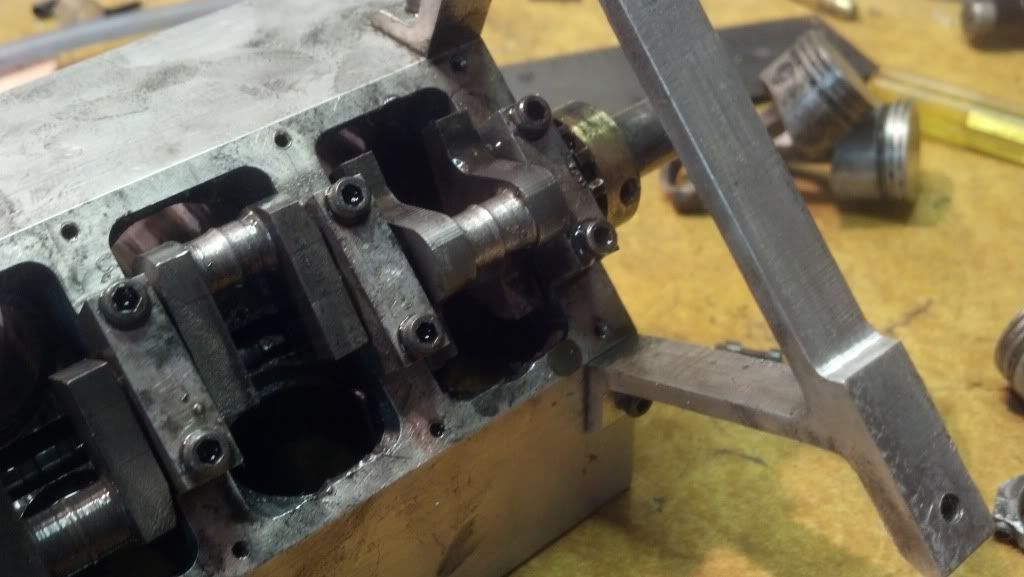

couldn't edit. This is what i meant

Yes I do. I just have that small radiator so it heats up real fast. I think if I did the same thing you do with the can I could get about the same time as you. 6 minutes is pretty darn good in my book.

Yes I do. I just have that small radiator so it heats up real fast. I think if I did the same thing you do with the can I could get about the same time as you. 6 minutes is pretty darn good in my book.