WW collets are 0.312-.313 in width and they are supposed to hold really small work very accurately. I got my self a few numbers from fee-bay and set out to make an adaptor for my Sherline lathe. This is a simple sleeve that fits into the Morse 1 taper of the spindle and holds the collet. Sherline sells the adaptor (and it's not too expensive), but I wanted to play a bit  .

.

Note that the 8mm version of such collets is a bit different in diameter (0.314-0.315) so one would need a different adaptor (same as this one with larger bore).

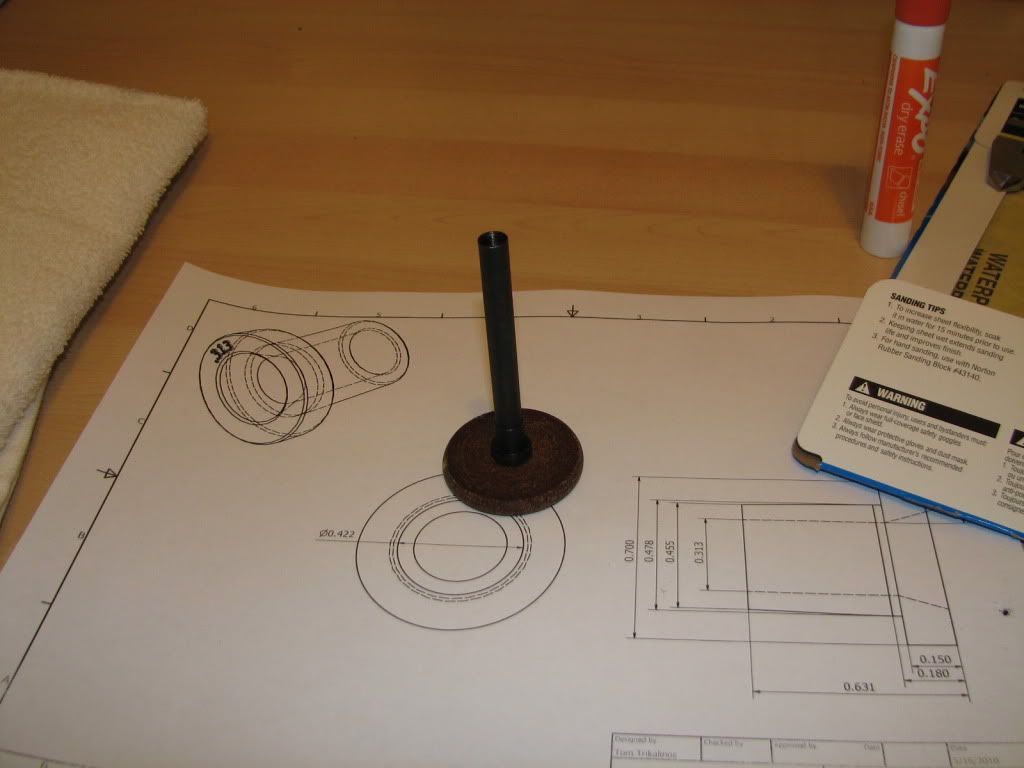

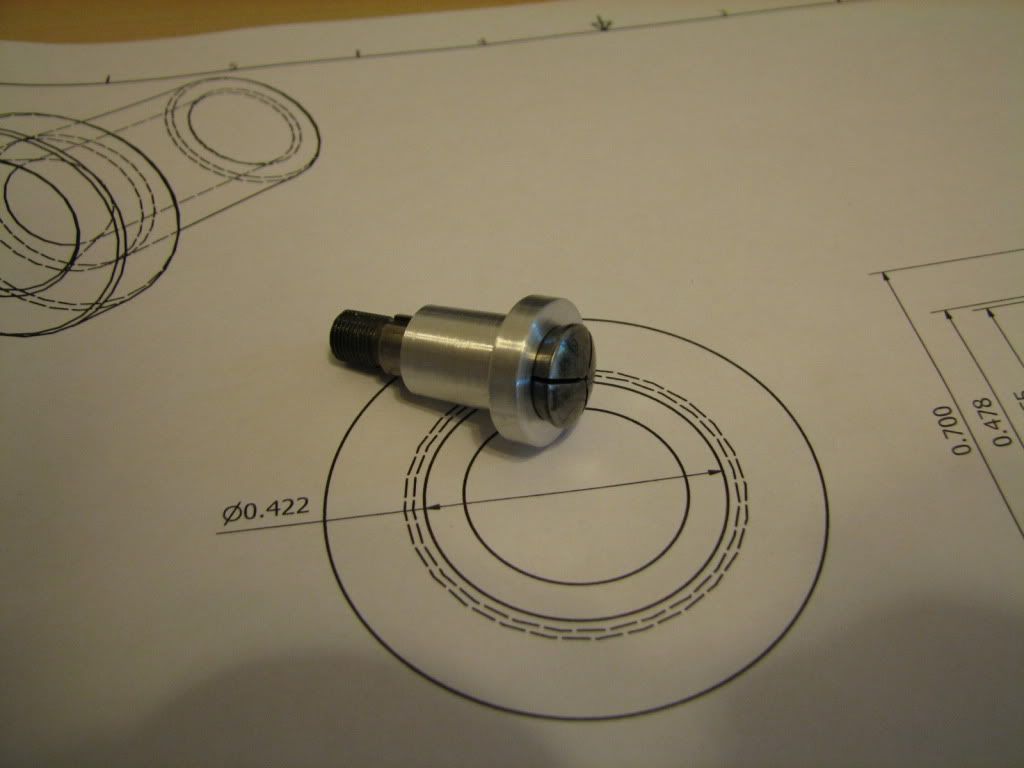

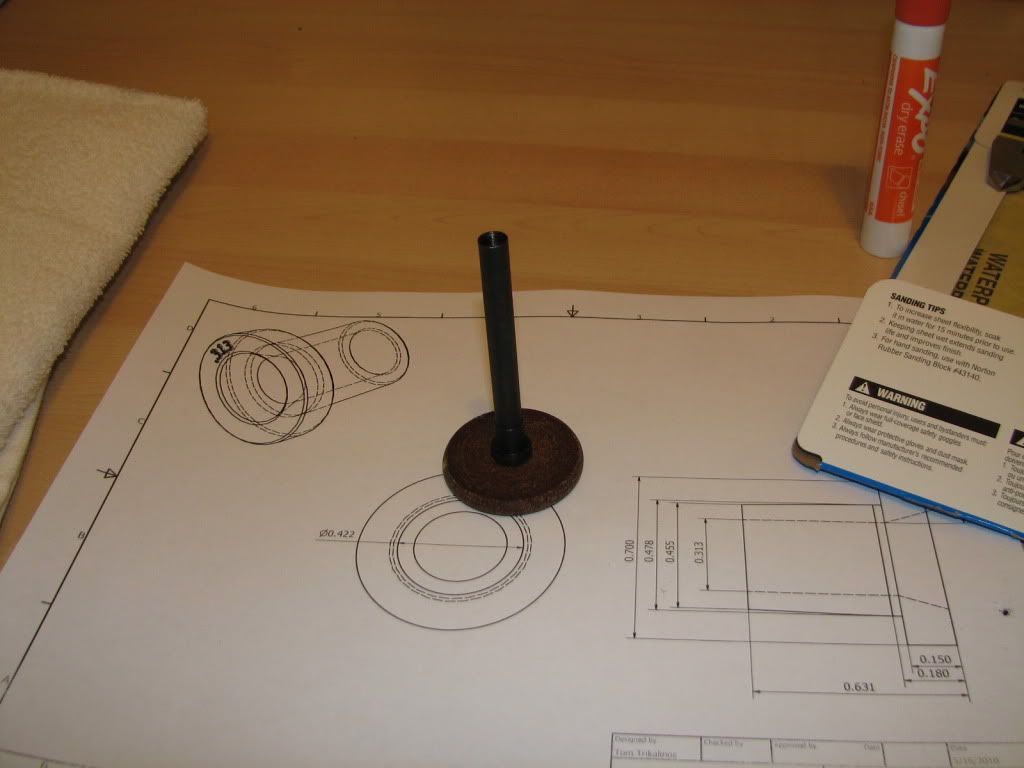

I posted the plan with the dimensions on this website:

http://web.me.com/ttrikalin/Machining/Machining_home.html

To ensure concentricity, the piece is machined in one setup. First, I indicated the MT1 of the spindle and set the compound cross slide to the correct angle.

I found good use for an el cheapo dentists mirror from Walgreens.

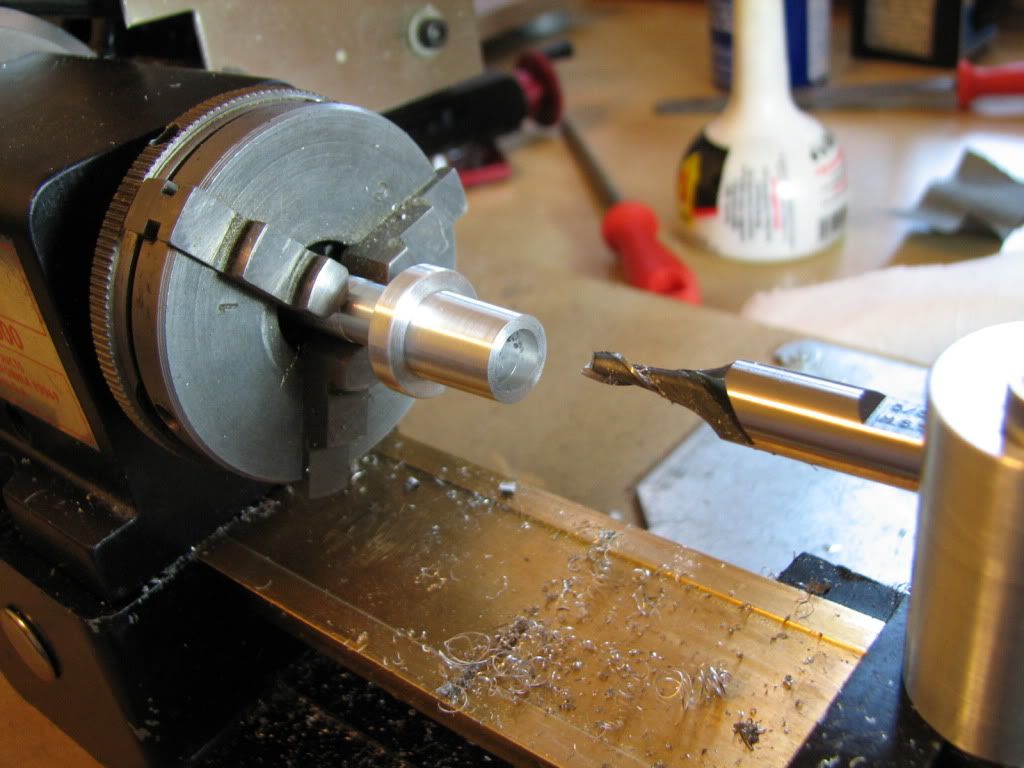

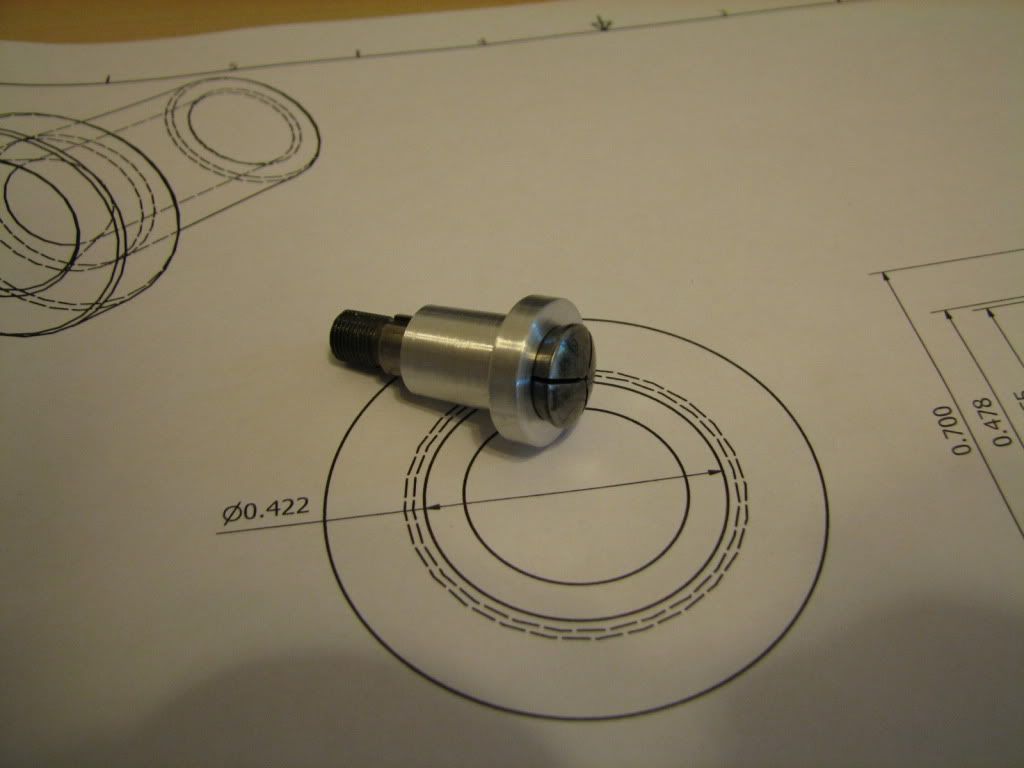

I chucked a 1.6 long piece of 0.75 diameter 6061 ally. After facing, I turned down to 0.700 a length of ~1. Then I turned down to 0.478 between 0.150 and 1 from the end. I had to use a combination of passes with left and right hand tools mounted on the compound cross slide. At this point the (already indicated in) compound cross slide is a back-cutting tool holder; I moved the whole cross slide the normal way.

Afterwards I turned the Morse taper with the compound cross slide. I used a left hand tool and I was cutting until 0.030 from the distal shoulder -- see plans.

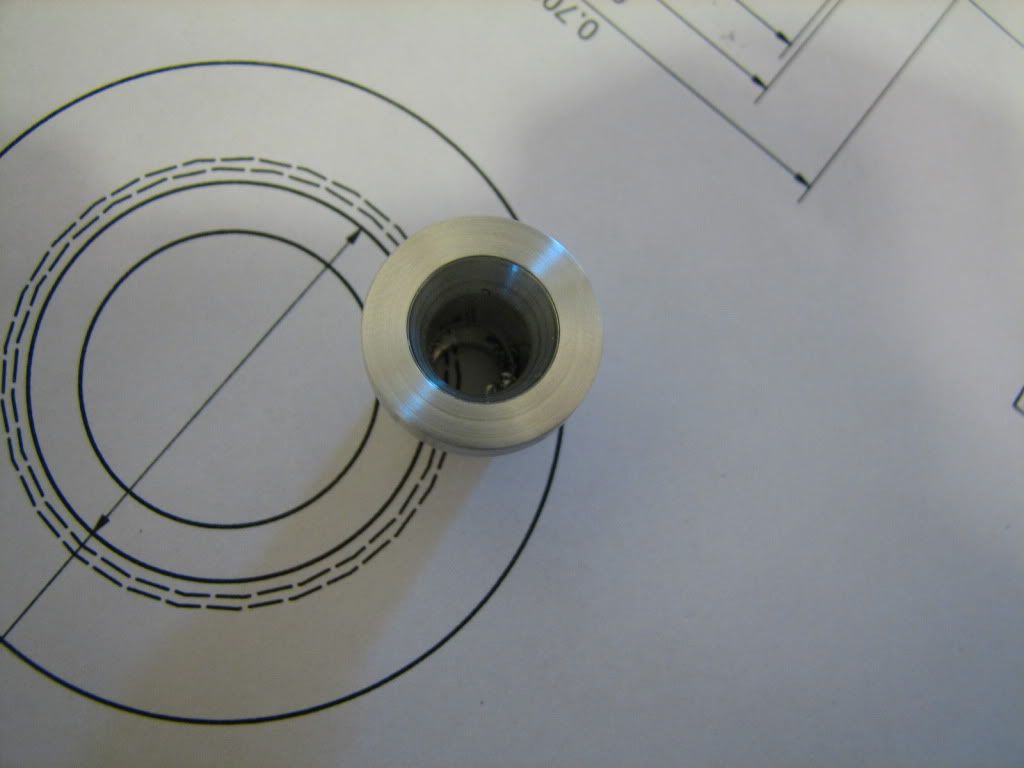

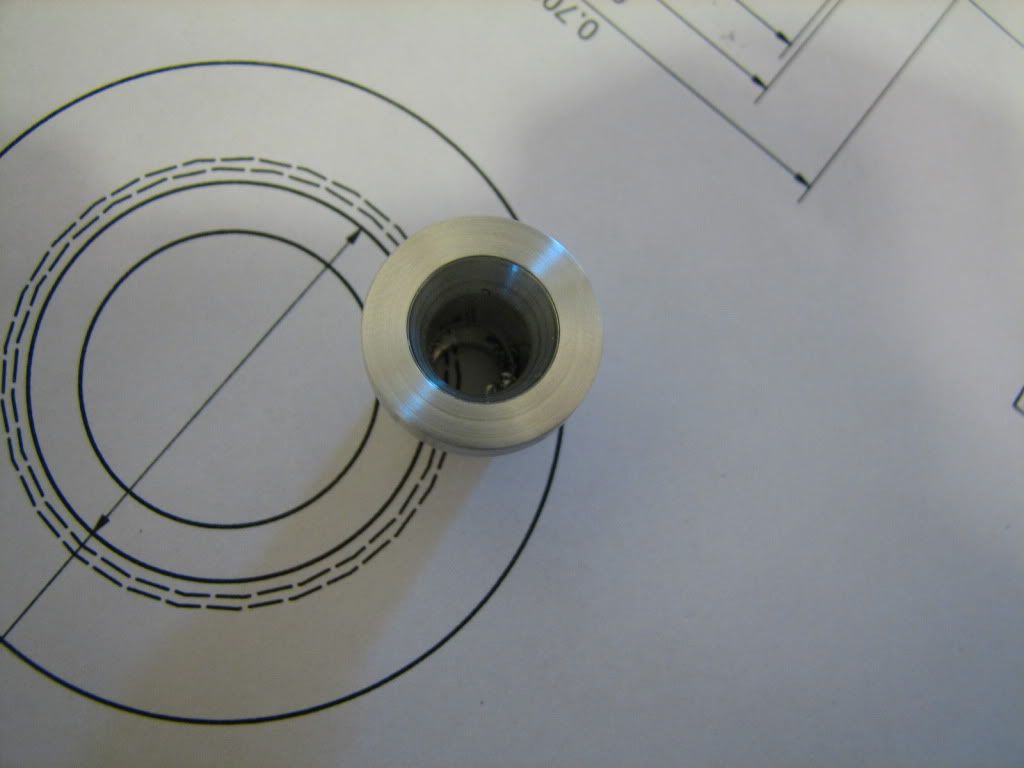

I drilled to 0.25 and then bored to 0.313, testing with a collet for fit. The final bore is a 20 degree taper to accept the head of the collet, as shown below.

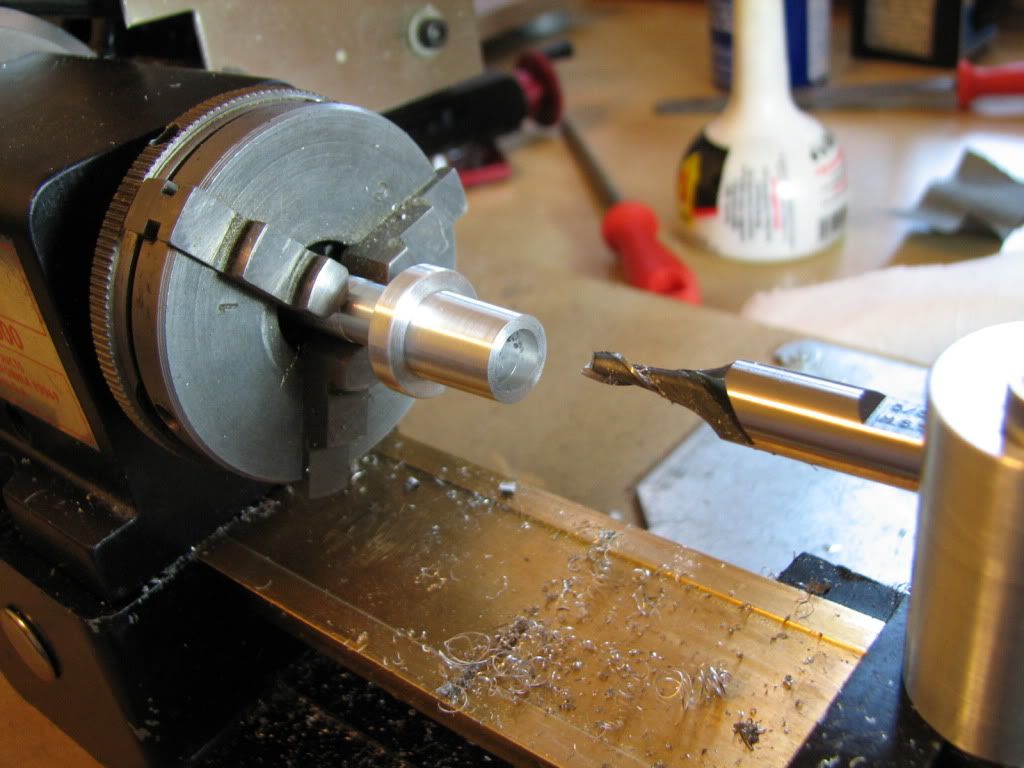

I only have a single boring bar that practically bores from 0.300 and wider... So to bore I am using 3/8 endmills held in my dial indicator mount. With the endmills I cannot bore deeper than approximately 0.6-0.7... and thus the bottom part of the adaptor below is still the drilled 0.25... You can barely see in the photo...

So i made a mandrel, and mounted the part on the lathe to clean up the bottom 0.1 or so... Here you can see the way I bored the back... I really have to make small boring bars... Oh well...

Concentricity is not a must in this final cleanup... it just frees the bore up.

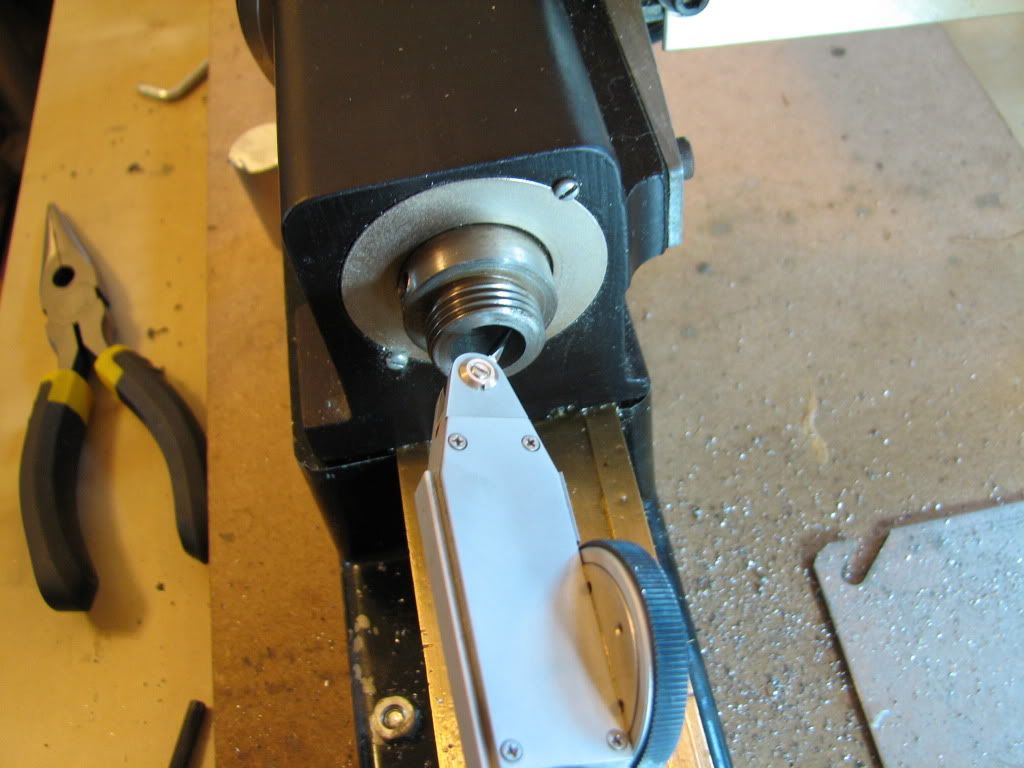

The WW collet fits very nicely with no play...

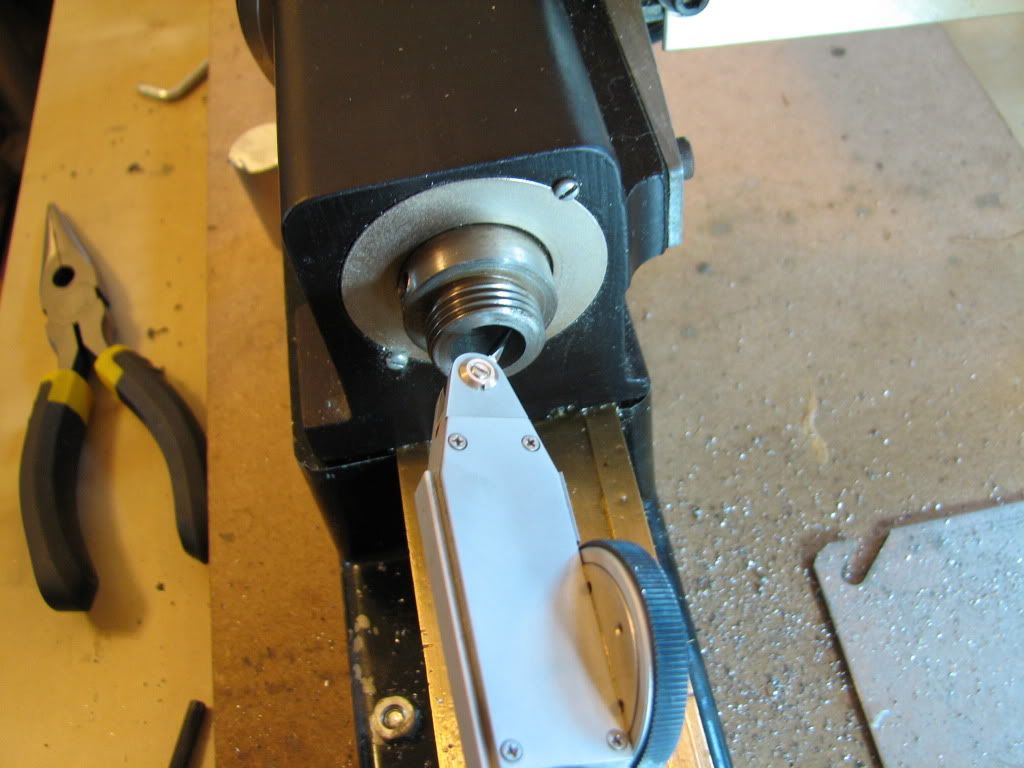

And sits nicely in the spindle...

The only thing left is to modify (elongate) this $5 drawbar from fee-bay to fit the lathe...

take care,

t

Note that the 8mm version of such collets is a bit different in diameter (0.314-0.315) so one would need a different adaptor (same as this one with larger bore).

I posted the plan with the dimensions on this website:

http://web.me.com/ttrikalin/Machining/Machining_home.html

To ensure concentricity, the piece is machined in one setup. First, I indicated the MT1 of the spindle and set the compound cross slide to the correct angle.

I found good use for an el cheapo dentists mirror from Walgreens.

I chucked a 1.6 long piece of 0.75 diameter 6061 ally. After facing, I turned down to 0.700 a length of ~1. Then I turned down to 0.478 between 0.150 and 1 from the end. I had to use a combination of passes with left and right hand tools mounted on the compound cross slide. At this point the (already indicated in) compound cross slide is a back-cutting tool holder; I moved the whole cross slide the normal way.

Afterwards I turned the Morse taper with the compound cross slide. I used a left hand tool and I was cutting until 0.030 from the distal shoulder -- see plans.

I drilled to 0.25 and then bored to 0.313, testing with a collet for fit. The final bore is a 20 degree taper to accept the head of the collet, as shown below.

I only have a single boring bar that practically bores from 0.300 and wider... So to bore I am using 3/8 endmills held in my dial indicator mount. With the endmills I cannot bore deeper than approximately 0.6-0.7... and thus the bottom part of the adaptor below is still the drilled 0.25... You can barely see in the photo...

So i made a mandrel, and mounted the part on the lathe to clean up the bottom 0.1 or so... Here you can see the way I bored the back... I really have to make small boring bars... Oh well...

Concentricity is not a must in this final cleanup... it just frees the bore up.

The WW collet fits very nicely with no play...

And sits nicely in the spindle...

The only thing left is to modify (elongate) this $5 drawbar from fee-bay to fit the lathe...

take care,

t