This is one that puzzles me. #5-40 is the perfect size for a 1/8" rod, yet none of the local Nut and Bolt stores in my end of the world stock it in nuts, bolts, nor set screws. When I first started to mess about with model steam engines last year, I bought a #5-40 tap and a #5-40 die, and they were special order and due to their 'Uncommoness" cost me over $100 to buy them. We have #10-24 for 3/16" rod, and we have associated thread sizes from there on up, but 1/8" rod seems to be a Bastard size.---And yet, #6-32 and #6-40 are called out as having a diameter of .131 to .137 which doesn't fit with any standard rod size that I know of.---Weird!!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why is #5-40 UNC such an orphan thread?

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Oddball? The common thread sizes would be 00, 0, 2, 4, 6, 8, 10, 12. 5-40 isn't as commonly used, or 3-48 for that matter. I needed a 1-72 die, which wasn't an off the shelf item either.

Good question though.

Possibly because 2 or 4 are close enough that 3 isn't needed? Maybe something to do with clearance drill sizes?

I've been in the machining trade for a good while and I don't recall hearing a reason for it.

Kevin

Good question though.

Possibly because 2 or 4 are close enough that 3 isn't needed? Maybe something to do with clearance drill sizes?

I've been in the machining trade for a good while and I don't recall hearing a reason for it.

Kevin

Brian:

Too late to help you now, but if you break one, check out Micro Fasteners (http://www.microfasteners.com/). I've dealt with them several times for nuts and bolts, and recently a pair of 5-40 plug taps for less than $10. (Bought a pair presuming I'll break one when I really don't want to wait for a replacement). They are perfectly happy shipping to Canada.

Cheers, Joe

Too late to help you now, but if you break one, check out Micro Fasteners (http://www.microfasteners.com/). I've dealt with them several times for nuts and bolts, and recently a pair of 5-40 plug taps for less than $10. (Bought a pair presuming I'll break one when I really don't want to wait for a replacement). They are perfectly happy shipping to Canada.

Cheers, Joe

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

Brian,

I had the same thoughts early in my machining days. When I first started cutting threads I was getting poor results even with a fairly good quality die. I would turn rods to the major diameter of the thread I was working with. Over time, in my limited experience, I've gotten much better results by reducing the major diameter of a rod I'm going to thread by 1-5% depending upon size and material. So even though 3/16" drill rod should be good to go for 10-32 threads, I always get better results by turning it down to 0.185" - 0.186". So, if I was going to make a #5 thread, I'd still want to take some material off of a 1/8" rod. The first time I tried threading a 0.250" rod for 1/4-20 threads using a die held in a tailstock dieholder the results were terrible. I thought I had a bad die. But when I reduce the rod diameter to 0.245" I get good results.

There may be other reasons that relate to scaling threads up or down by common factors. ??? ??? Just my thoughts

Cheers,

Phil

I had the same thoughts early in my machining days. When I first started cutting threads I was getting poor results even with a fairly good quality die. I would turn rods to the major diameter of the thread I was working with. Over time, in my limited experience, I've gotten much better results by reducing the major diameter of a rod I'm going to thread by 1-5% depending upon size and material. So even though 3/16" drill rod should be good to go for 10-32 threads, I always get better results by turning it down to 0.185" - 0.186". So, if I was going to make a #5 thread, I'd still want to take some material off of a 1/8" rod. The first time I tried threading a 0.250" rod for 1/4-20 threads using a die held in a tailstock dieholder the results were terrible. I thought I had a bad die. But when I reduce the rod diameter to 0.245" I get good results.

There may be other reasons that relate to scaling threads up or down by common factors. ??? ??? Just my thoughts

Cheers,

Phil

I've wondered that too. The 'odd' sizes 1,3,5,7,9 (are there even the last two?) don't get much shrift, even though they do nicely on stock size rods. #12 seems pretty unused as well.

Deep in Machinery's Handbook, along with every other piece of information in the known world, is the thread major size to use for cutting with a die, depending on the class of thread you want, but it's not that easy to extract. I think Marv may have a program for it though.. I have a vague memory of seeing something like that.

Deep in Machinery's Handbook, along with every other piece of information in the known world, is the thread major size to use for cutting with a die, depending on the class of thread you want, but it's not that easy to extract. I think Marv may have a program for it though.. I have a vague memory of seeing something like that.

ChooChooMike

Well-Known Member

- Joined

- Jan 5, 2008

- Messages

- 864

- Reaction score

- 13

PM Research has a model builder selection of taps/dies including MTP ones :

http://www.pmresearchinc.com/store/search.php?mode=search&page=3

5-40 taps for $4.95 (left hand too !)

http://www.pmresearchinc.com/store/product.php?productid=3430&cat=0&page=3

5-40 die $13.10 (left hand die also):

http://www.pmresearchinc.com/store/product.php?productid=3450&cat=0&page=2

PM Research has been a good source of stuff for me !!

http://www.pmresearchinc.com/store/search.php?mode=search&page=3

5-40 taps for $4.95 (left hand too !)

http://www.pmresearchinc.com/store/product.php?productid=3430&cat=0&page=3

5-40 die $13.10 (left hand die also):

http://www.pmresearchinc.com/store/product.php?productid=3450&cat=0&page=2

PM Research has been a good source of stuff for me !!

G

greenie

Guest

If I'm not mistaken, the #5-40 tpi is used mainly in the auto industry, that's one of the reasons you dont find it freely available at your local hardware store.

Where-as if you go to the auto el-cheapo joints, you'll find plenty of them, there are a couple of other threads used mainly by the auto industry as well.

Where-as if you go to the auto el-cheapo joints, you'll find plenty of them, there are a couple of other threads used mainly by the auto industry as well.

DICKEYBIRD

Well-Known Member

- Joined

- Sep 27, 2007

- Messages

- 653

- Reaction score

- 46

5-40 is the propeller screw size on Cox .049/.051 model aircraft engines. 5-40 is a little out of the ordinary but I've always been able to order allen head screws, taps & dies from several sources at reasonable prices.

It's the fault of the bean counters, trying to reduce the number of thread sizes to cut costs.

You shouldn't have to pay a hundred bucks for 5-40 taps and dies though. Check out http://www.victornet.com/cgi-bin/victor/subdepartments.html?did=100&id=4bRPzWvz

I've never had occasion to use them, but they list all manner of uncommon taps and dies, for reasonable prices.

You shouldn't have to pay a hundred bucks for 5-40 taps and dies though. Check out http://www.victornet.com/cgi-bin/victor/subdepartments.html?did=100&id=4bRPzWvz

I've never had occasion to use them, but they list all manner of uncommon taps and dies, for reasonable prices.

compound driver 2

Well-Known Member

- Joined

- Jan 3, 2008

- Messages

- 207

- Reaction score

- 1

why not use 5BA rather? its bang on the money for 1/8th rod.

come to that if your pushed make your own tap and die or tap and die plate for 5-40

its a nice job just needs some thinking about and a bit of tool steel.

come to that if your pushed make your own tap and die or tap and die plate for 5-40

its a nice job just needs some thinking about and a bit of tool steel.

mklotz

Well-Known Member

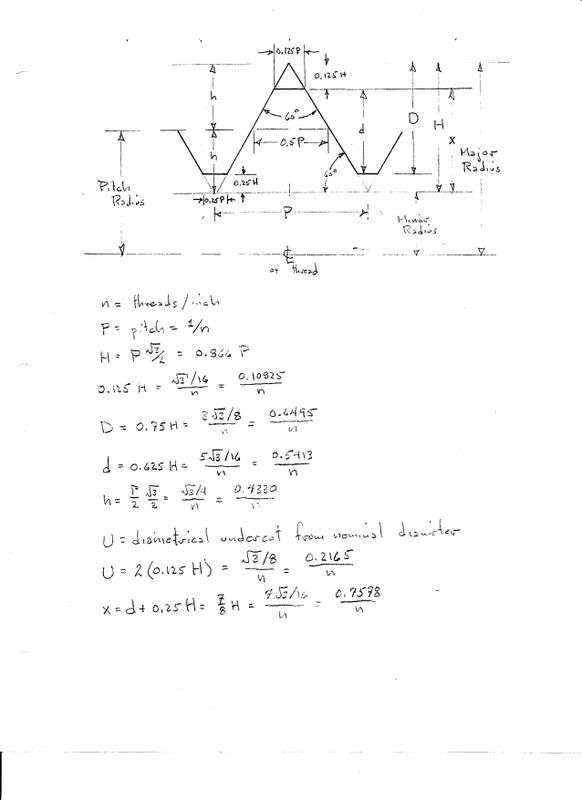

Standard threads have a flat on the crest of the thread. The width of this flat is P/8, where P is the pitch of the thread (P = 1/n, where n is the thread pitch in tpi).

If one works out the height of the small triangular section formed by this flat and then doubles that, the resulting number represents the amount by which the nominal diameter (0.125" in the case of 5-40) should be reduced to yield the requisite flat after cutting the thread.

In the attached diagram this undercut is labeled:

U = diametrical undercut from nominal diameter

and is calculated as:

U = (sqrt(3)/8)/n = 0.2165/n

So, for a 5-40 thread, we have n=40 and U=0.2165/40 = 0.0054". Turning the rod down to 0.120" before threading should work just fine.

Note that the formula is valid for all sixty degree threads.

Since Marv was so kind as to post that, I popped his 0.2165/n formula into a spreadsheet of the UNF and UNS sizes I'm likely to use and made a little table, attached below. The 'Ext Thread Dia' column is the one to turn stock to for external threading.

I like printing tables for the shop after destroying several calculators in various workshop-related methods.

View attachment ExternalThreadTable.pdf

I like printing tables for the shop after destroying several calculators in various workshop-related methods.

View attachment ExternalThreadTable.pdf

rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

The 5-40 thread is still a common size in the gun smiting trade.

I am lucky enough to have an industrial/hardware supplier near by who

caters to that market. Going to that store and asking for 5-40 bolts

is answered with: "Hex or socket head? What grade and how many?"

It is strange that the 5-40 has become a bastard size here in the USA

with it's major diameter being a perfect Imperial 1/8" ???

Rick

I am lucky enough to have an industrial/hardware supplier near by who

caters to that market. Going to that store and asking for 5-40 bolts

is answered with: "Hex or socket head? What grade and how many?"

It is strange that the 5-40 has become a bastard size here in the USA

with it's major diameter being a perfect Imperial 1/8" ???

Rick

Lew Hartswick

Well-Known Member

- Joined

- Sep 20, 2007

- Messages

- 505

- Reaction score

- 10

There must no be any other electronic folks here. One of the most common

screw terminal barrier strips uses 5-40 screws. At least up till I retired 11 years

ago. They may all be metric now.

They may all be metric now.

...lew...

screw terminal barrier strips uses 5-40 screws. At least up till I retired 11 years

ago.

...lew...

K

Kludge

Guest

Try here for not only 5-40 but a few other unusual trheads:

http://www.brownells.com/

Best regards,

Kludge

http://www.brownells.com/

Best regards,

Kludge

Similar threads

- Replies

- 1

- Views

- 2K

- Replies

- 1

- Views

- 1K

- Replies

- 55

- Views

- 12K