Well tonight's a bust

This is why we wear Safety Glasses

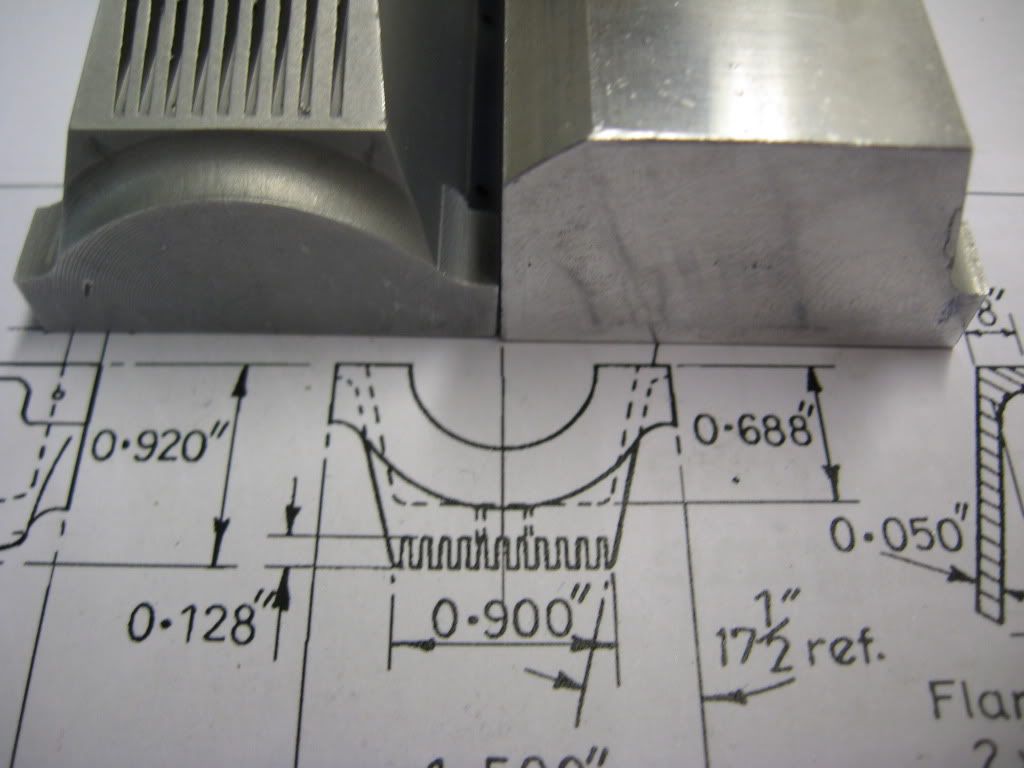

Nothing hit me but you never know. I was separating the upper crankcase from the lower.....almost done.....bang.

Thanks for McMaster Carr I got my order in before 7PM and I should have 2 saws for tomorrow. This way the weekend wont be a bust. I don't want to break down the set up in the mill. So tonight will be the sci channel or the history channel and a couple of cold ones!

I had a machinist at work a few jobs back tell me to use Alcohol (not the drinking kind) when cutting Alu. He said it works better than oil. Anybody agree?

Tony

This is why we wear Safety Glasses

Nothing hit me but you never know. I was separating the upper crankcase from the lower.....almost done.....bang.

Thanks for McMaster Carr I got my order in before 7PM and I should have 2 saws for tomorrow. This way the weekend wont be a bust. I don't want to break down the set up in the mill. So tonight will be the sci channel or the history channel and a couple of cold ones!

I had a machinist at work a few jobs back tell me to use Alcohol (not the drinking kind) when cutting Alu. He said it works better than oil. Anybody agree?

Tony