You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Whittle Aero V8 WIP

- Thread starter cobra428

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Hi George,

The deck gets a radius cut tangent to that edge where the bolts come out. I'm just waiting till I have the front and back mounted to make the cut. It's like the oil pan but smaller and full length thru front and rear to match the profile (1/16dp 1/16R).

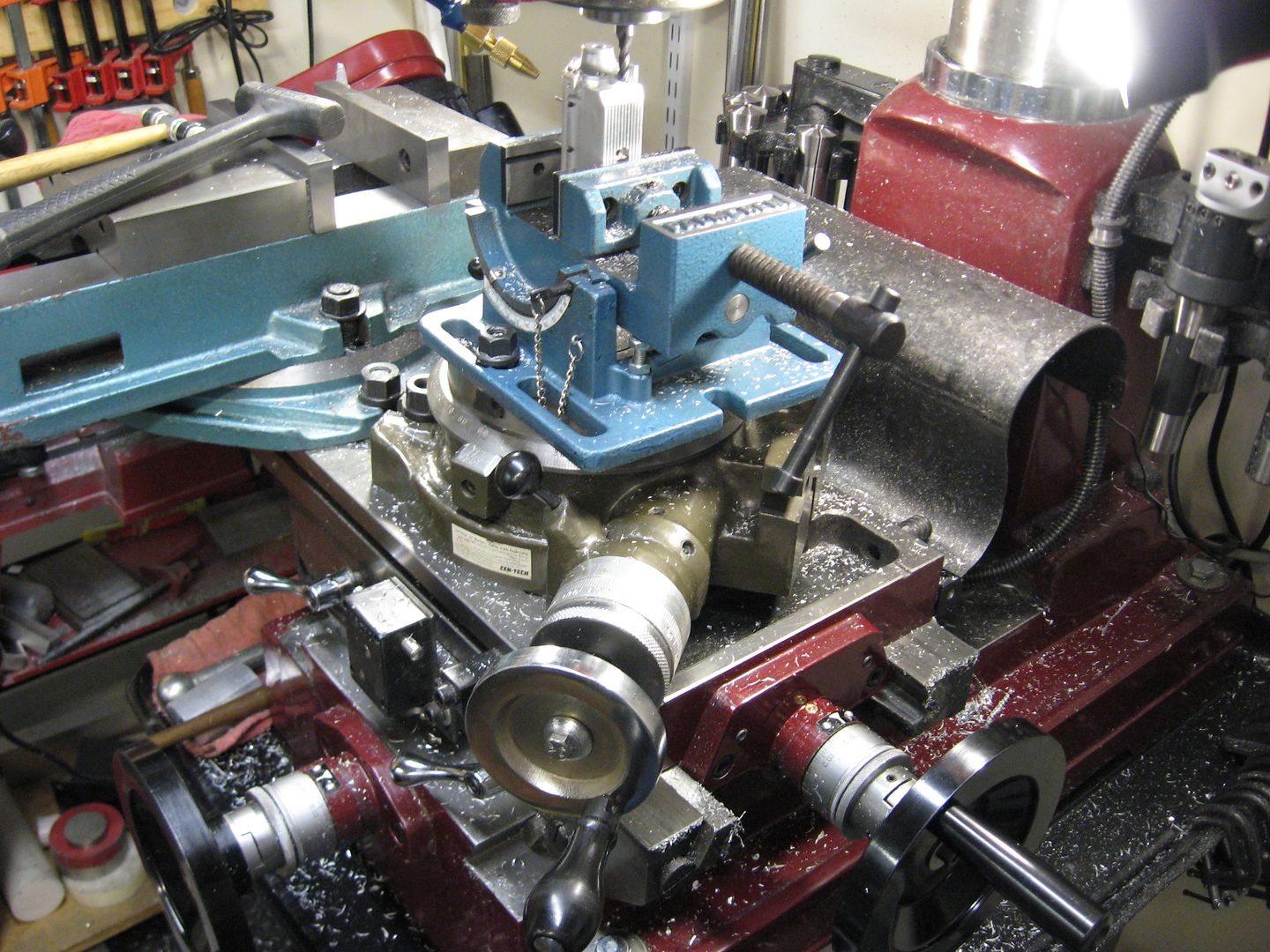

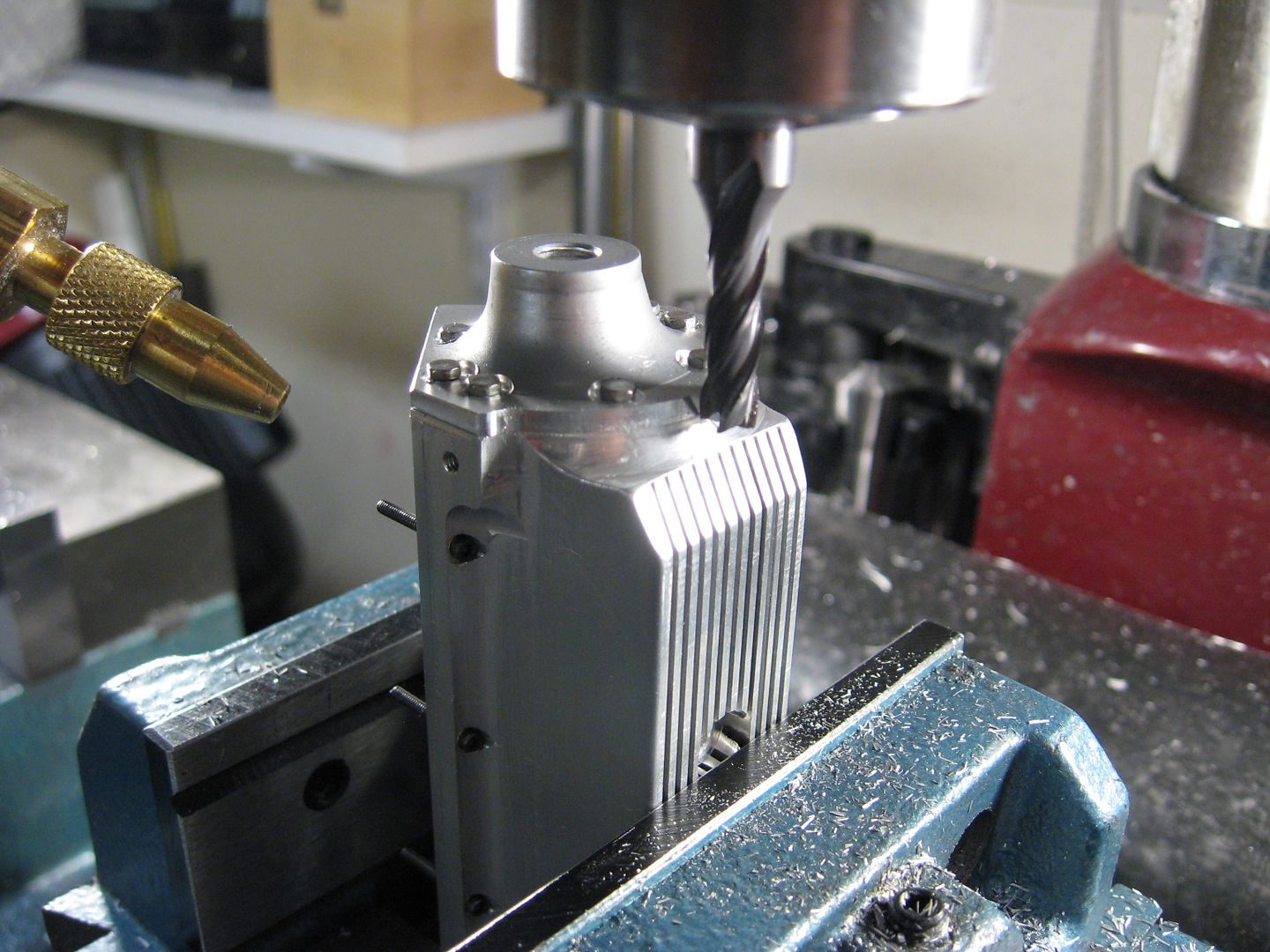

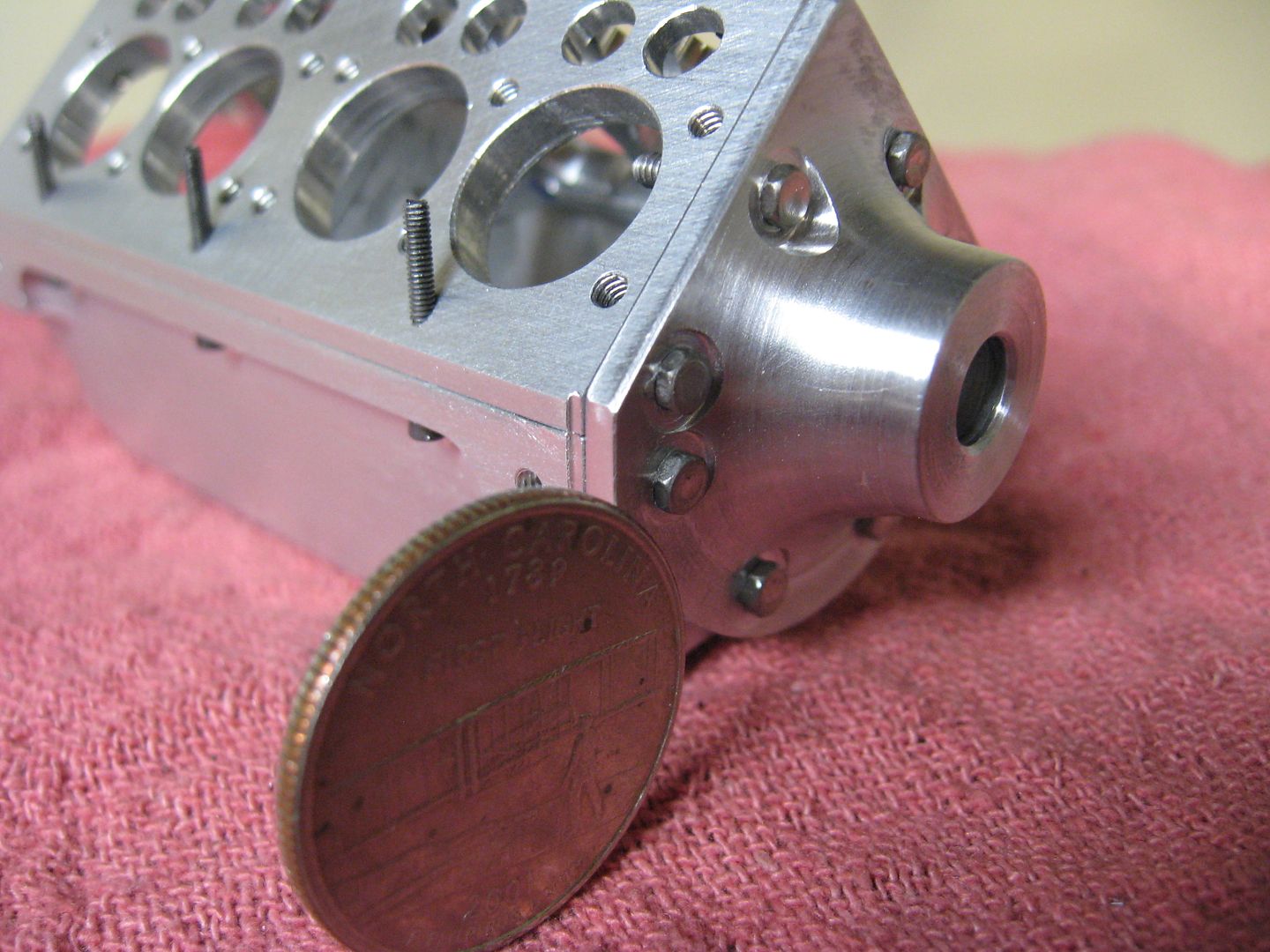

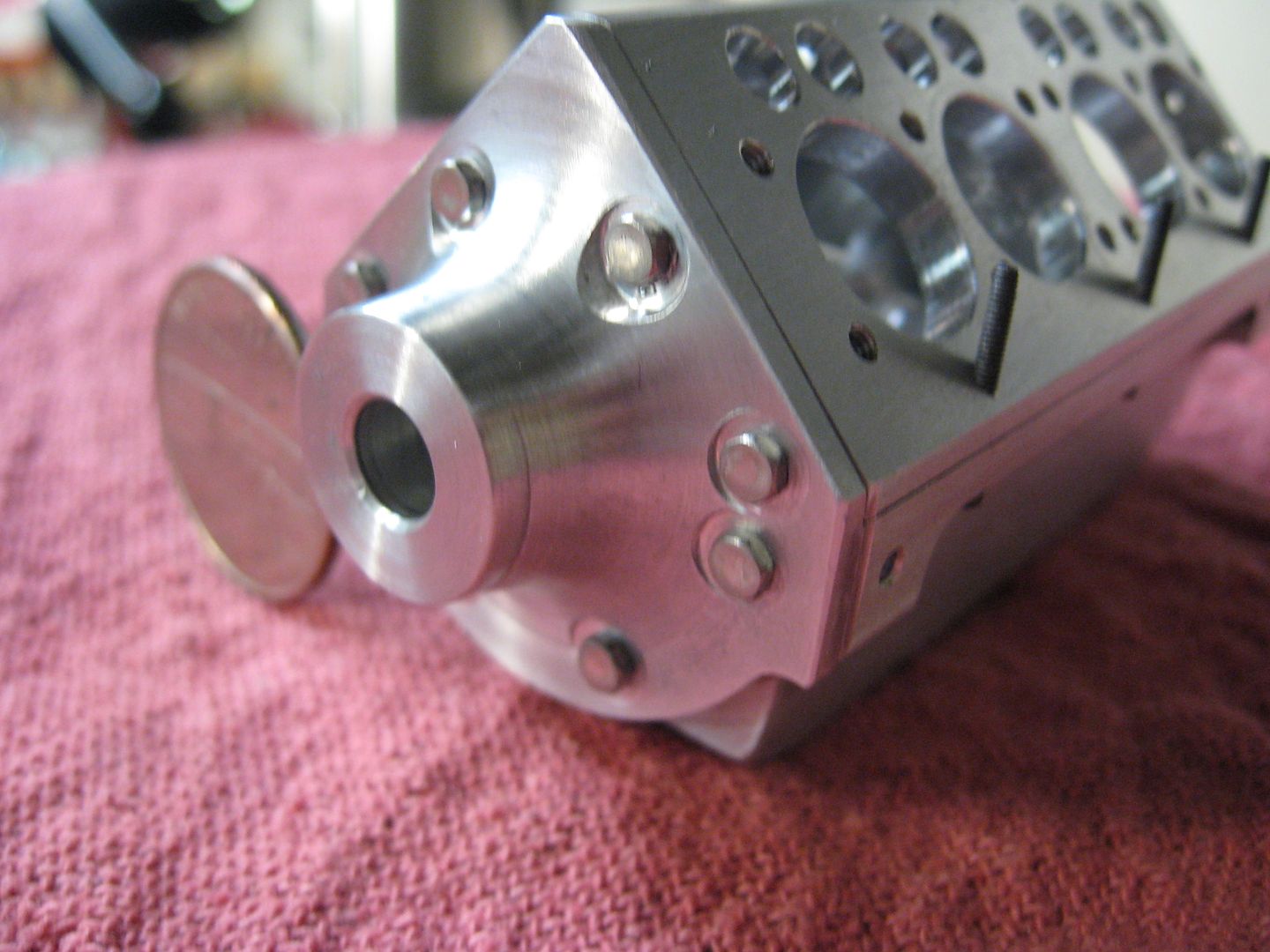

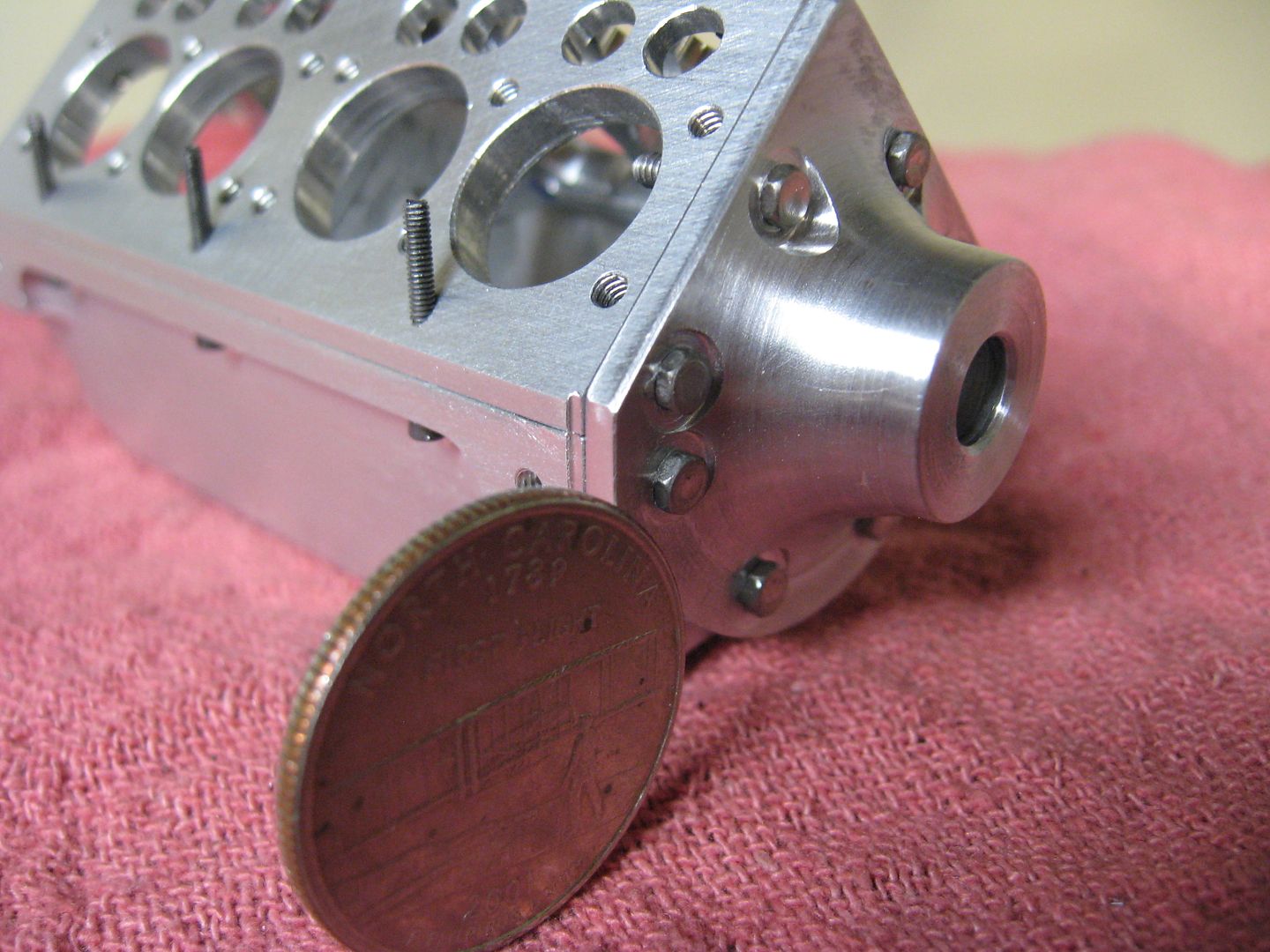

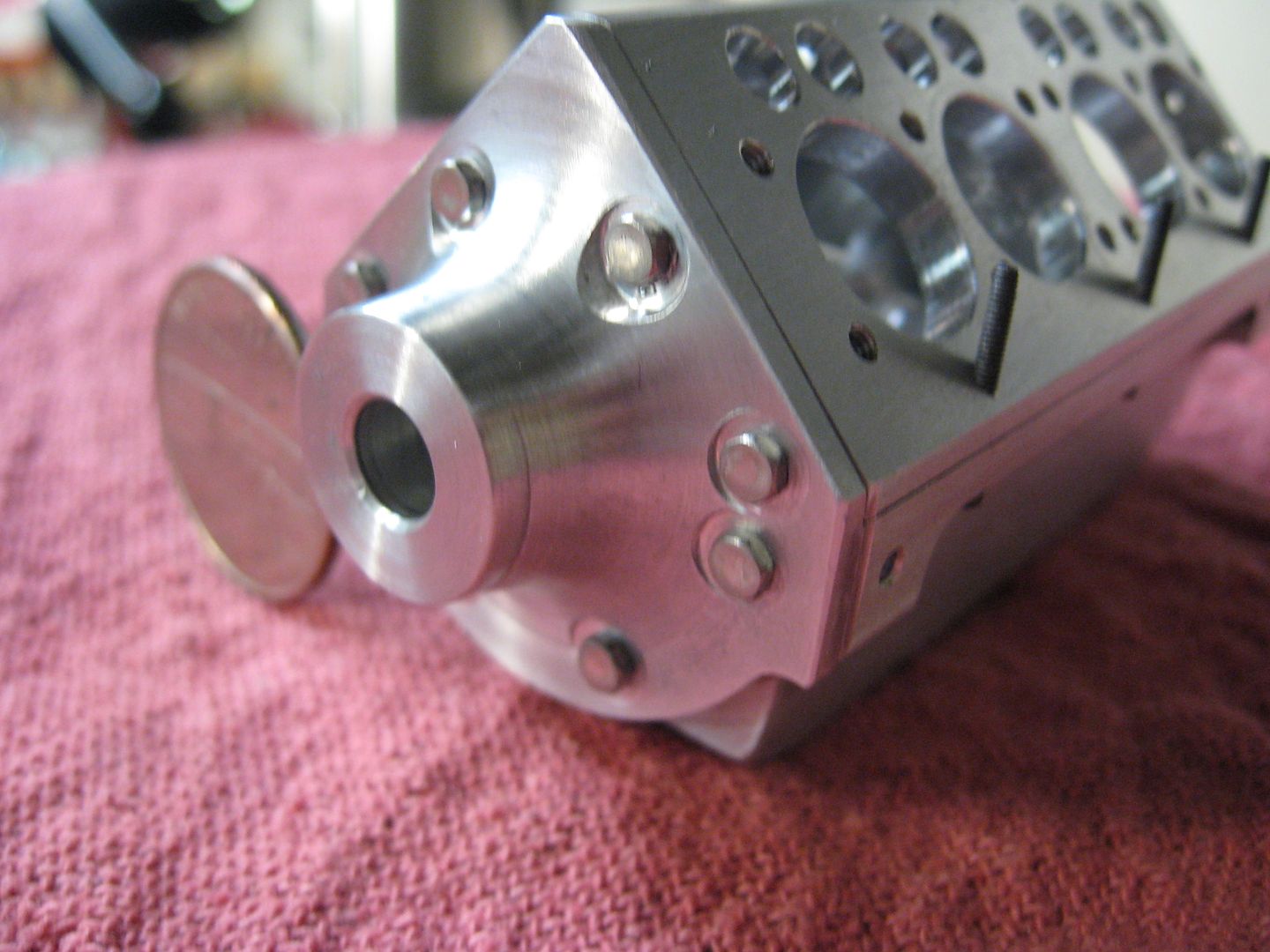

Tonight's fun

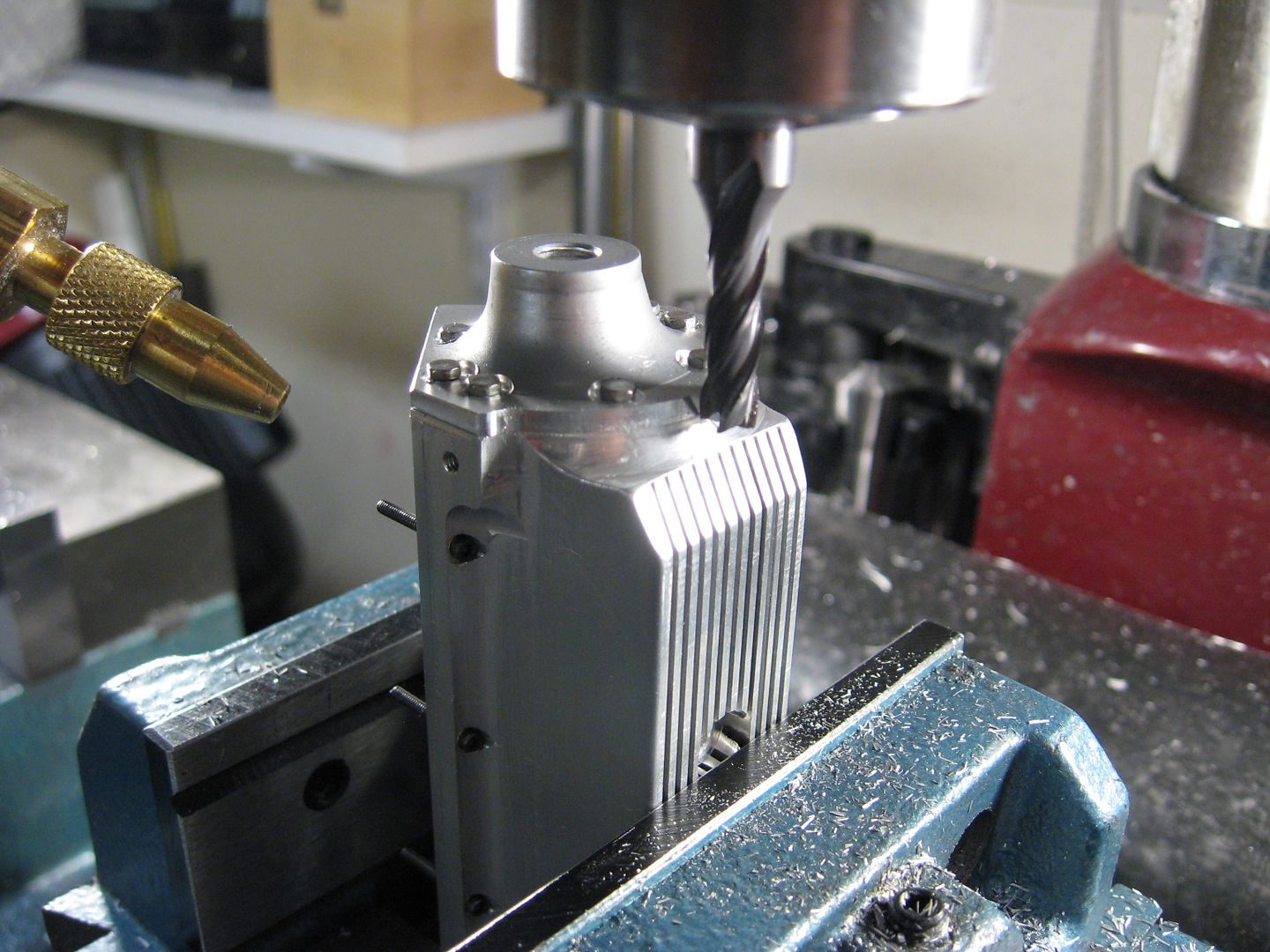

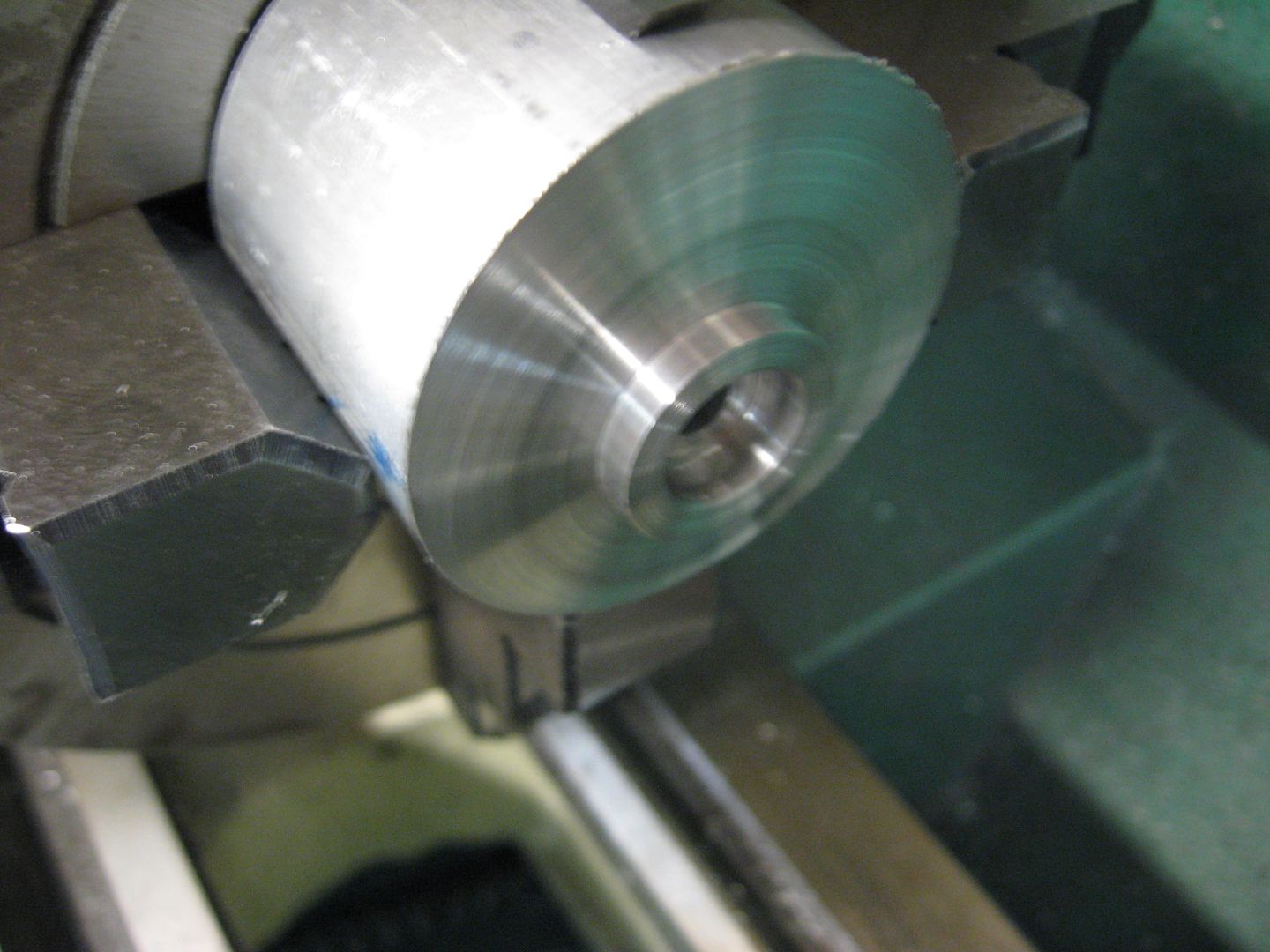

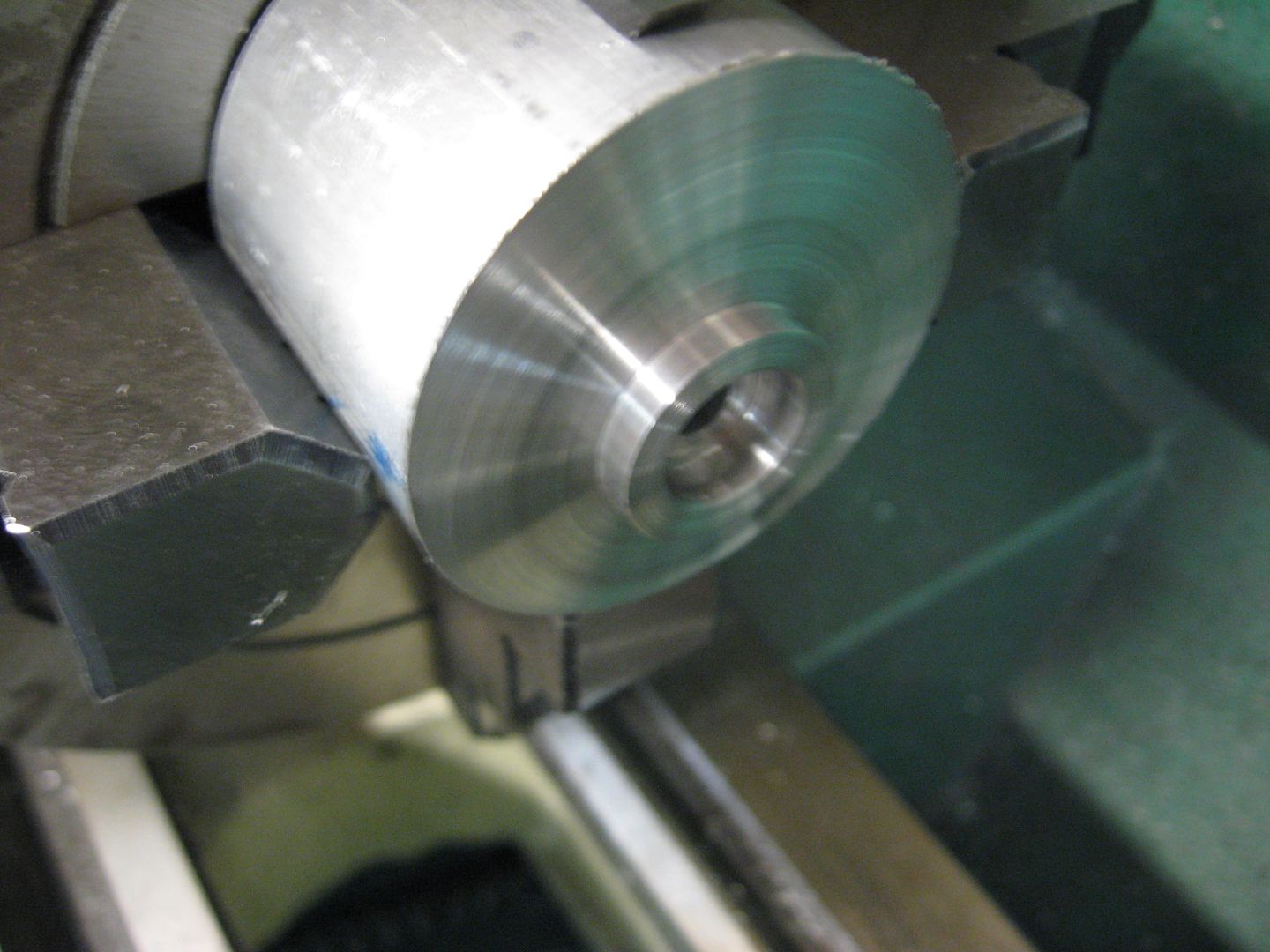

Radius the nose

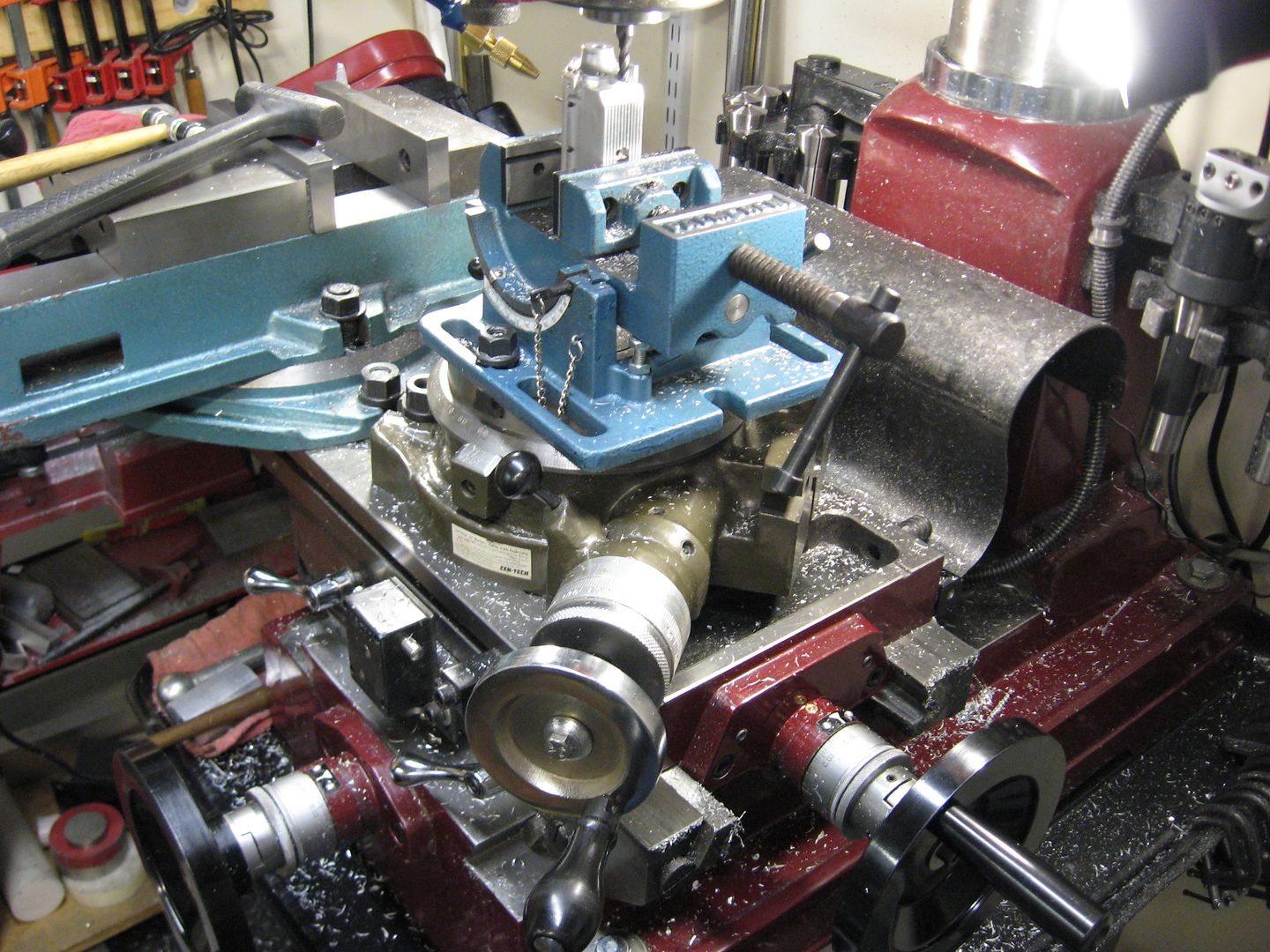

Using this setup (fine adjustment tools in the backround)

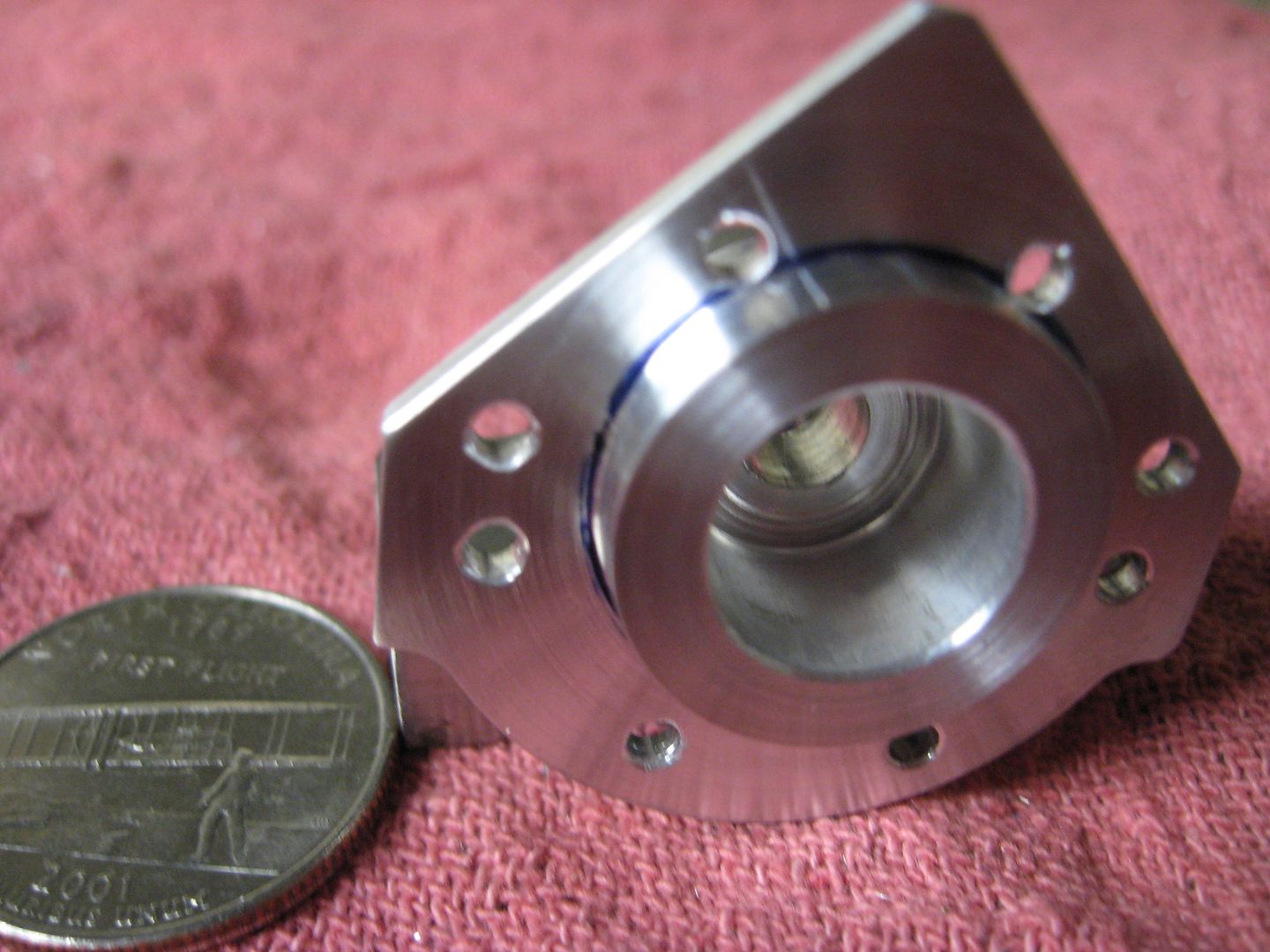

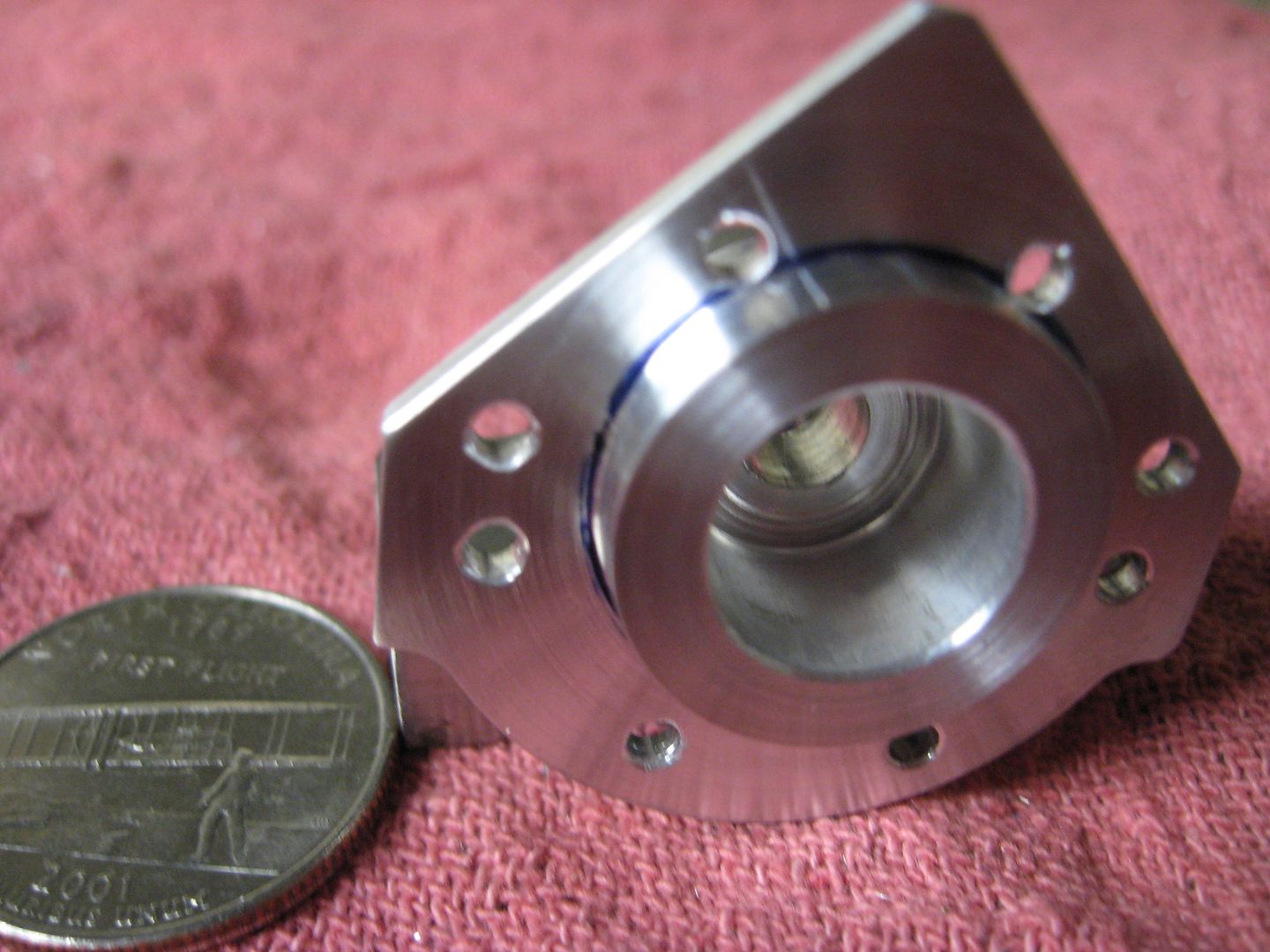

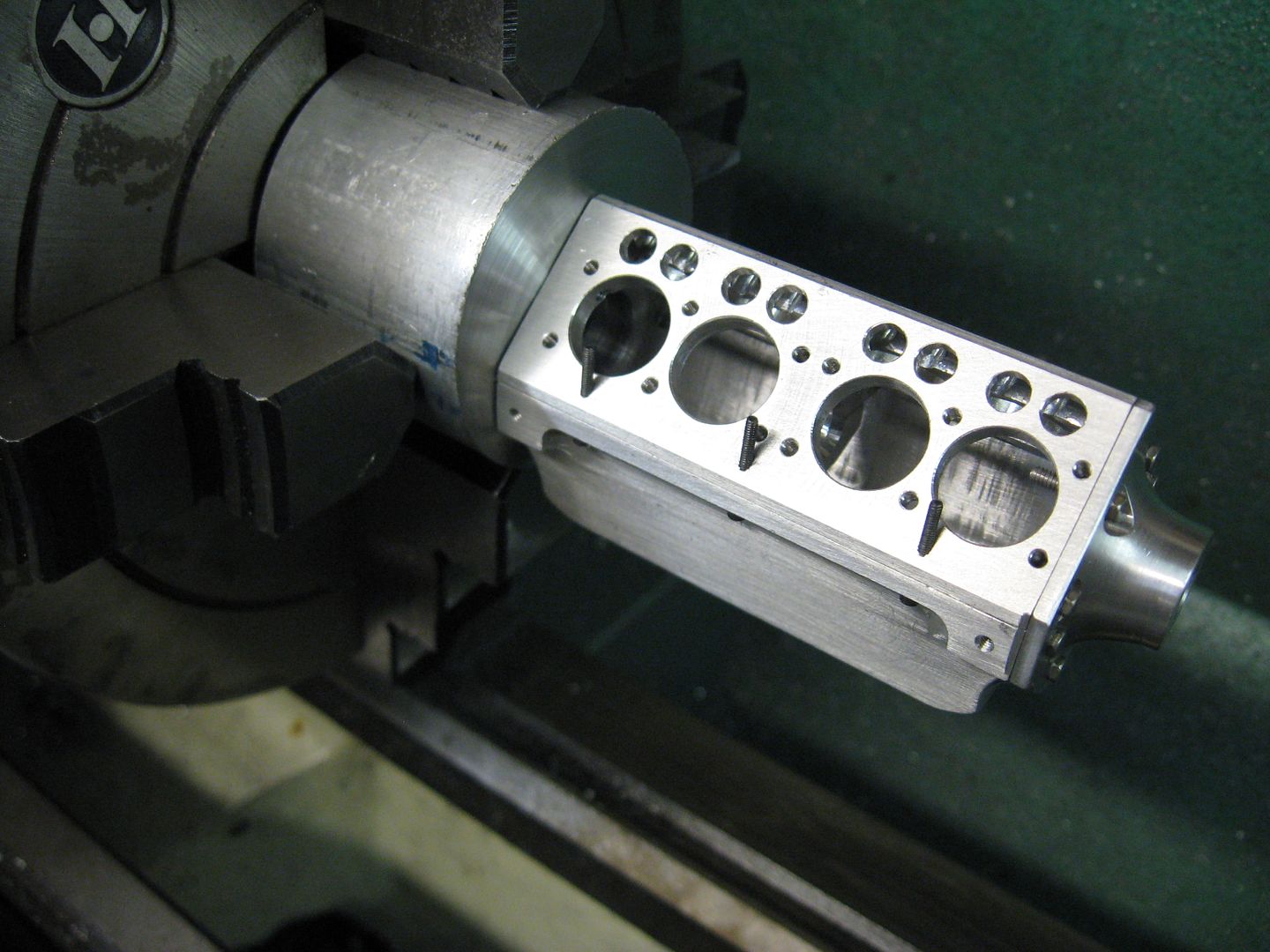

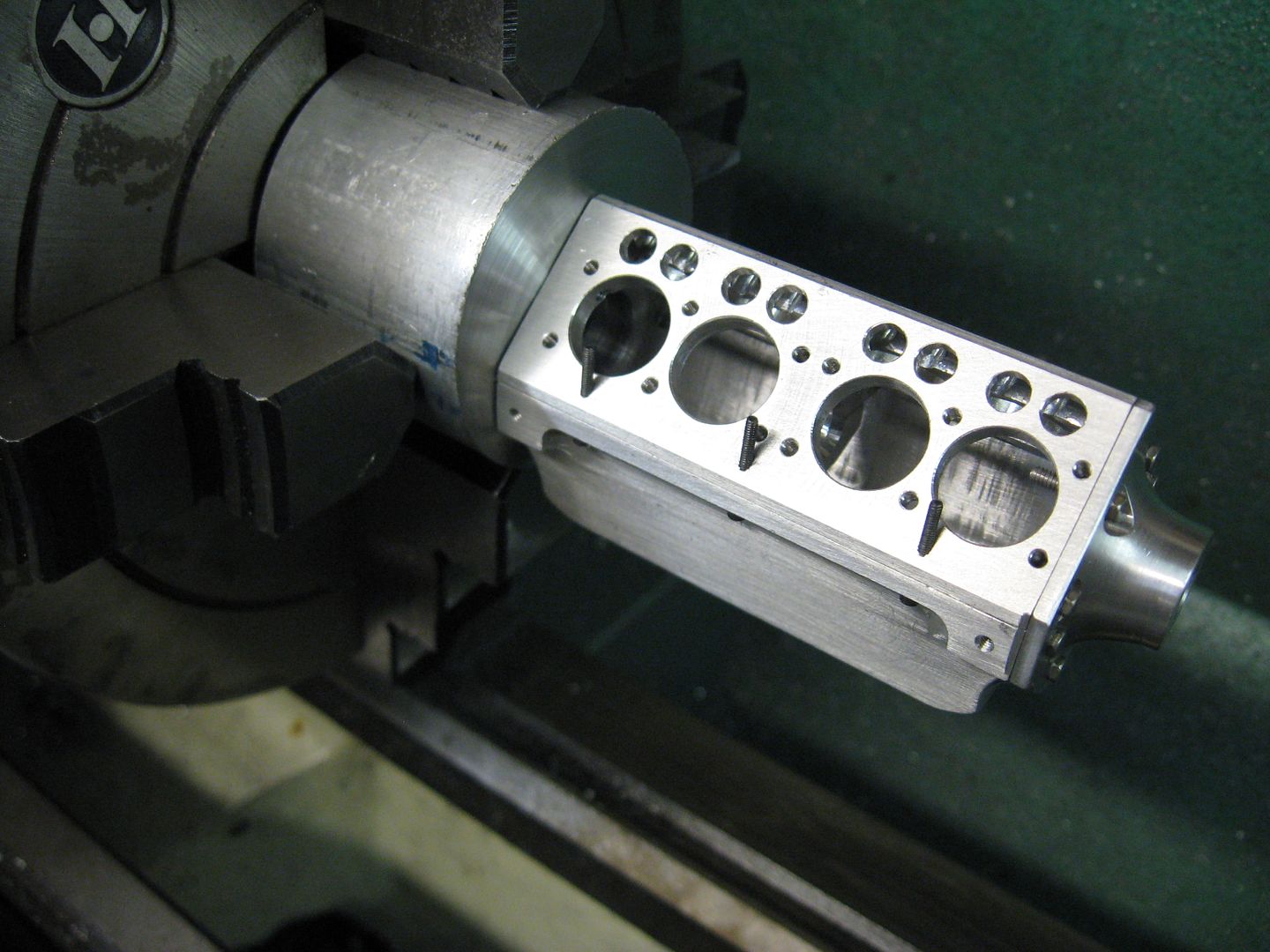

The inside

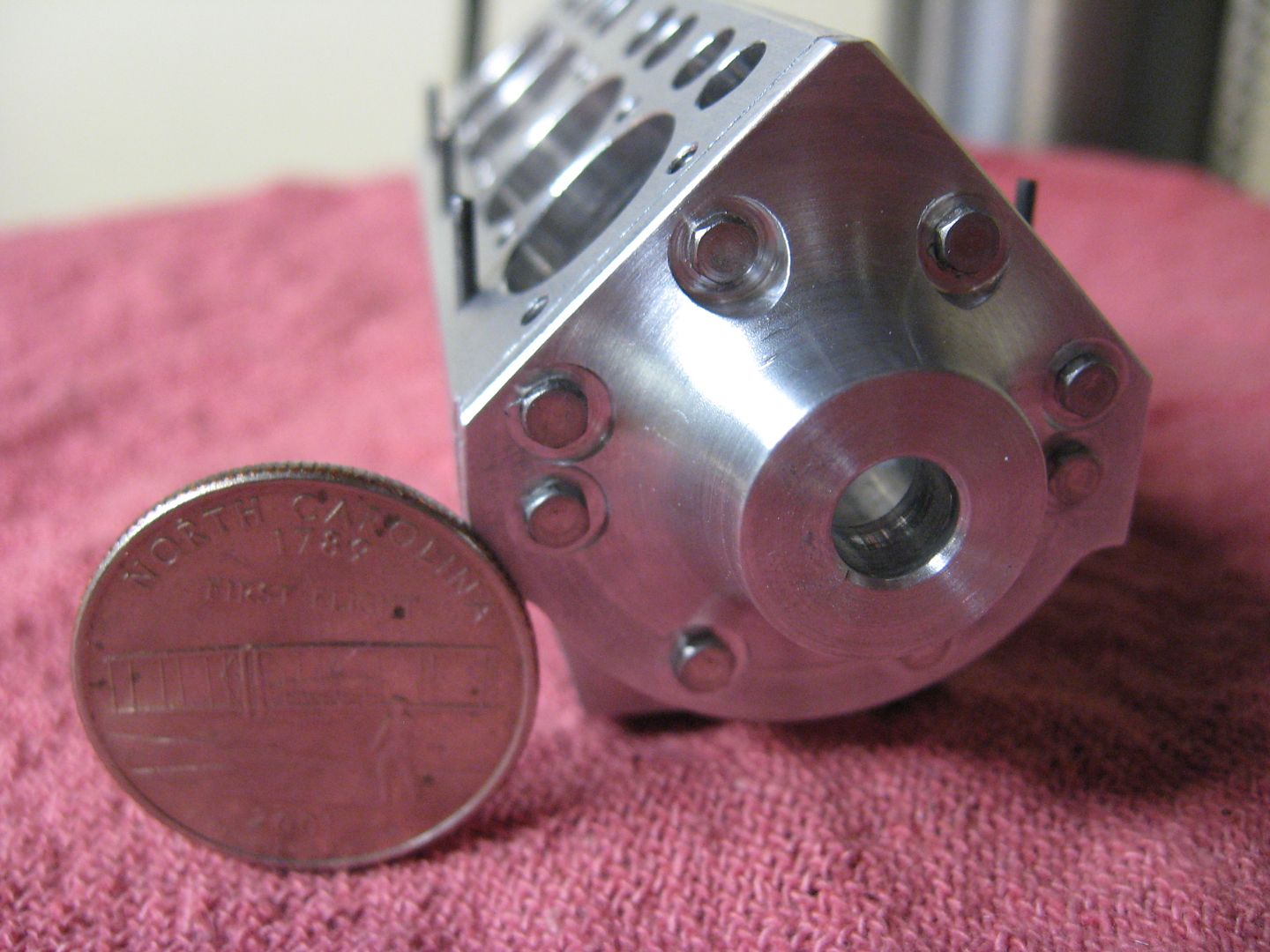

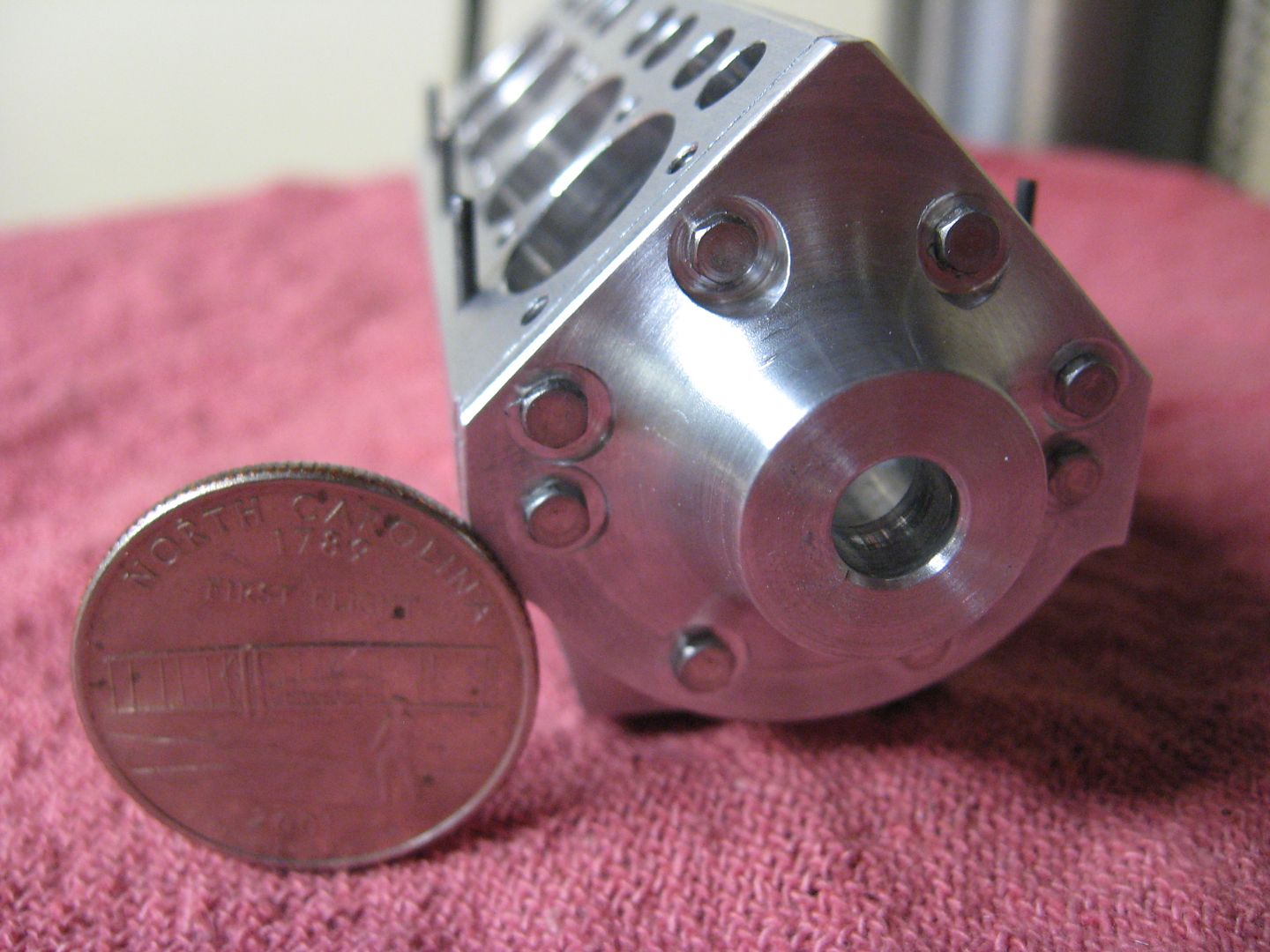

The outside

Don't know if those spot faces will stay

That's all folks

Tony

The deck gets a radius cut tangent to that edge where the bolts come out. I'm just waiting till I have the front and back mounted to make the cut. It's like the oil pan but smaller and full length thru front and rear to match the profile (1/16dp 1/16R).

Tonight's fun

Radius the nose

Using this setup (fine adjustment tools in the backround)

The inside

The outside

Don't know if those spot faces will stay

That's all folks

Tony

Thanks Dean,

The more I look at it (and I do look at it and pet it :big Brass bolts would add a nice contrast. I'm just not sure of their stress capability in this application. I'm pretty sure they'd be fine but.....

Brass bolts would add a nice contrast. I'm just not sure of their stress capability in this application. I'm pretty sure they'd be fine but.....

Tony

The more I look at it (and I do look at it and pet it :big

Tony

cobra428 said:Thanks Dean,

The more I look at it (and I do look at it and pet it :bigBrass bolts would add a nice contrast. I'm just not sure of their stress capability in this application. I'm pretty sure they'd be fine but.....

Tony

Sure can't blame you for giving it a fond caress.

Maybe George would know if brass cap screws would be strong enough. Are they 2-56?

Dean

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Nicely done Tony.

Very exciting build.

Very exciting build.

- Joined

- Jul 16, 2007

- Messages

- 2,988

- Reaction score

- 1,060

Now that's a set up!!! Great work on the radiusing Tony. As far as using brass, I wouldn't use it in a critical area. The tensile on brass is about 1/3 of CRS. Although I don't generally use socket head screws I think they would look good on an aircraft type engine. I think using stainless socket head screw would even be that much better.

George

George

Thanks George,

I forgot about the plans on the web. It would be a lot easier for you to look at them than me explaining about features in the parts. I can't use my hands to explain!!

http://www.model-engineer.co.uk/news/article.asp?a=6070

Those are stainless Hex heads screws I'm using except for the pan those are steel soc heads I'd like to do something about that but no room for a nut driver spot face. Still thinking on that.

Zee,Ron thanks for your continuing support

Tony

I forgot about the plans on the web. It would be a lot easier for you to look at them than me explaining about features in the parts. I can't use my hands to explain!!

http://www.model-engineer.co.uk/news/article.asp?a=6070

Those are stainless Hex heads screws I'm using except for the pan those are steel soc heads I'd like to do something about that but no room for a nut driver spot face. Still thinking on that.

Zee,Ron thanks for your continuing support

Tony

Hi Jeff,

I don't think I heard of Concept Models but you never know. Soon as I search I'll go....Oh Yeah. The radial is 1/4 scale. I was thinking of a 1/4 scale Stearman even though it had a P&W. Your right the Fleets had a J5. Decisions, decisions, decisions. I have a little time to think that one over. I need to make a DH-51 for the V8 too.

It looks much like a Gypsy Moth.

Got a little done tonight (very little)

Started the rear timing gear cover.

Pasted a 6mm drill rod from front to rear, went through like butter....thank god!

Time to do some CAD work to get the cords. I know it looks a bit large but I plan to cut the out line then saw the cover portion off, then cut the gear cavity's

Tony

I don't think I heard of Concept Models but you never know. Soon as I search I'll go....Oh Yeah. The radial is 1/4 scale. I was thinking of a 1/4 scale Stearman even though it had a P&W. Your right the Fleets had a J5. Decisions, decisions, decisions. I have a little time to think that one over. I need to make a DH-51 for the V8 too.

It looks much like a Gypsy Moth.

Got a little done tonight (very little)

Started the rear timing gear cover.

Pasted a 6mm drill rod from front to rear, went through like butter....thank god!

Time to do some CAD work to get the cords. I know it looks a bit large but I plan to cut the out line then saw the cover portion off, then cut the gear cavity's

Tony

Mike Thanks,

I can hear that DH-51 just purrrring along now! Even though I'm a giant scale high power acro guy.....It would be nice!

Jeff I just thought of it WACO YMF! Even though it's cowled .....but sweet!

If anybody is interested I did some CAD work for the rear case coords.

PDF DXF attached

Tony

PS the below pdf and dfx no good. I realized that I didn't set the upper outside radii (.06) to the proper size to account for a washer. 0-80 washer .188d. I'll fix tonight

View attachment C__Drawings_Whittle V8_REAR CASE.pdf

View attachment REAR CASE.dxf

I can hear that DH-51 just purrrring along now! Even though I'm a giant scale high power acro guy.....It would be nice!

Jeff I just thought of it WACO YMF! Even though it's cowled .....but sweet!

If anybody is interested I did some CAD work for the rear case coords.

PDF DXF attached

Tony

PS the below pdf and dfx no good. I realized that I didn't set the upper outside radii (.06) to the proper size to account for a washer. 0-80 washer .188d. I'll fix tonight

View attachment C__Drawings_Whittle V8_REAR CASE.pdf

View attachment REAR CASE.dxf