SBWHART,

The way I drop parts with my fat fingers....they just might. scratch.gif where the heck could it have gone :shrug:

solver

Ahhhh it's calling your name to, I see.

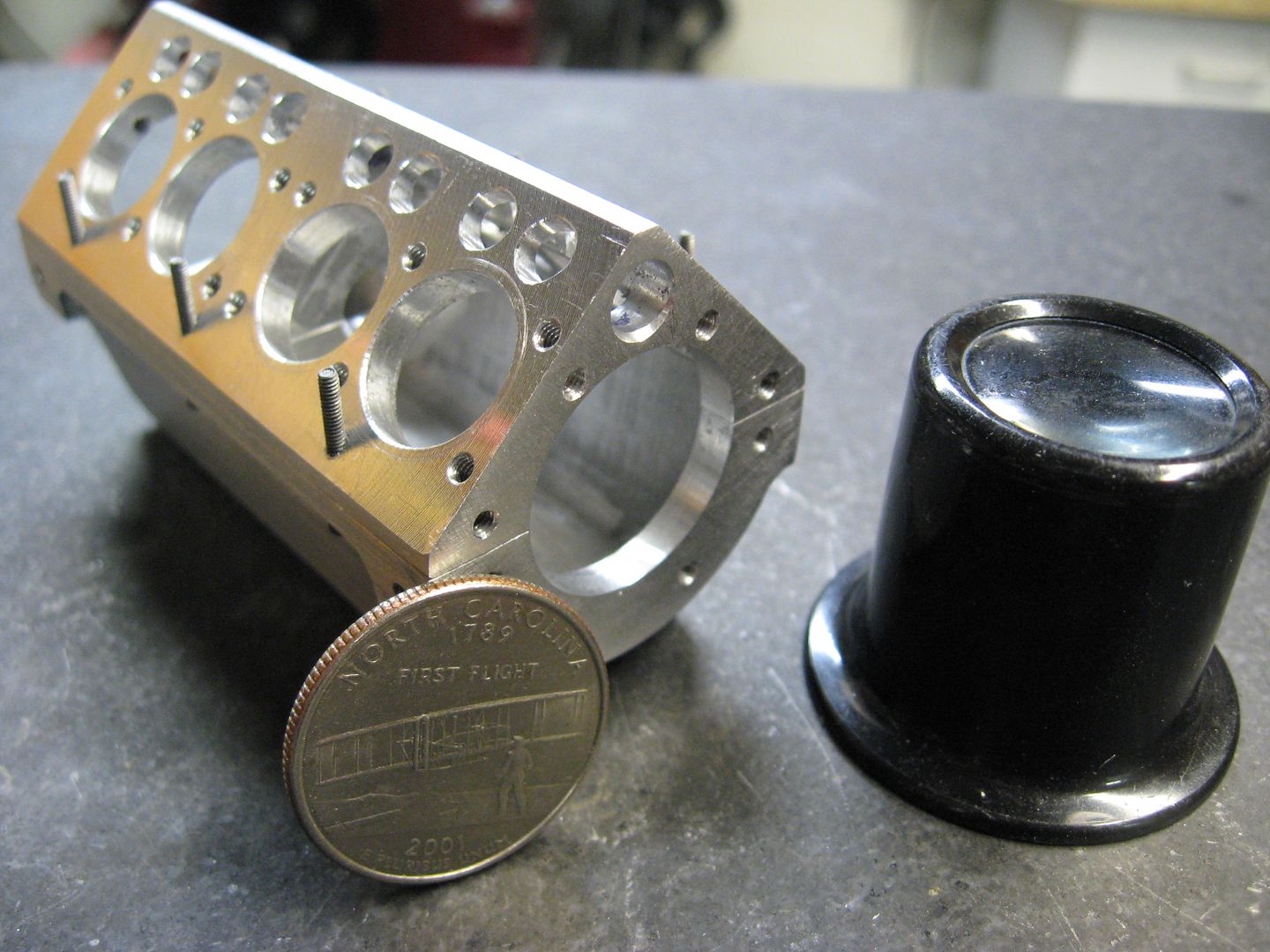

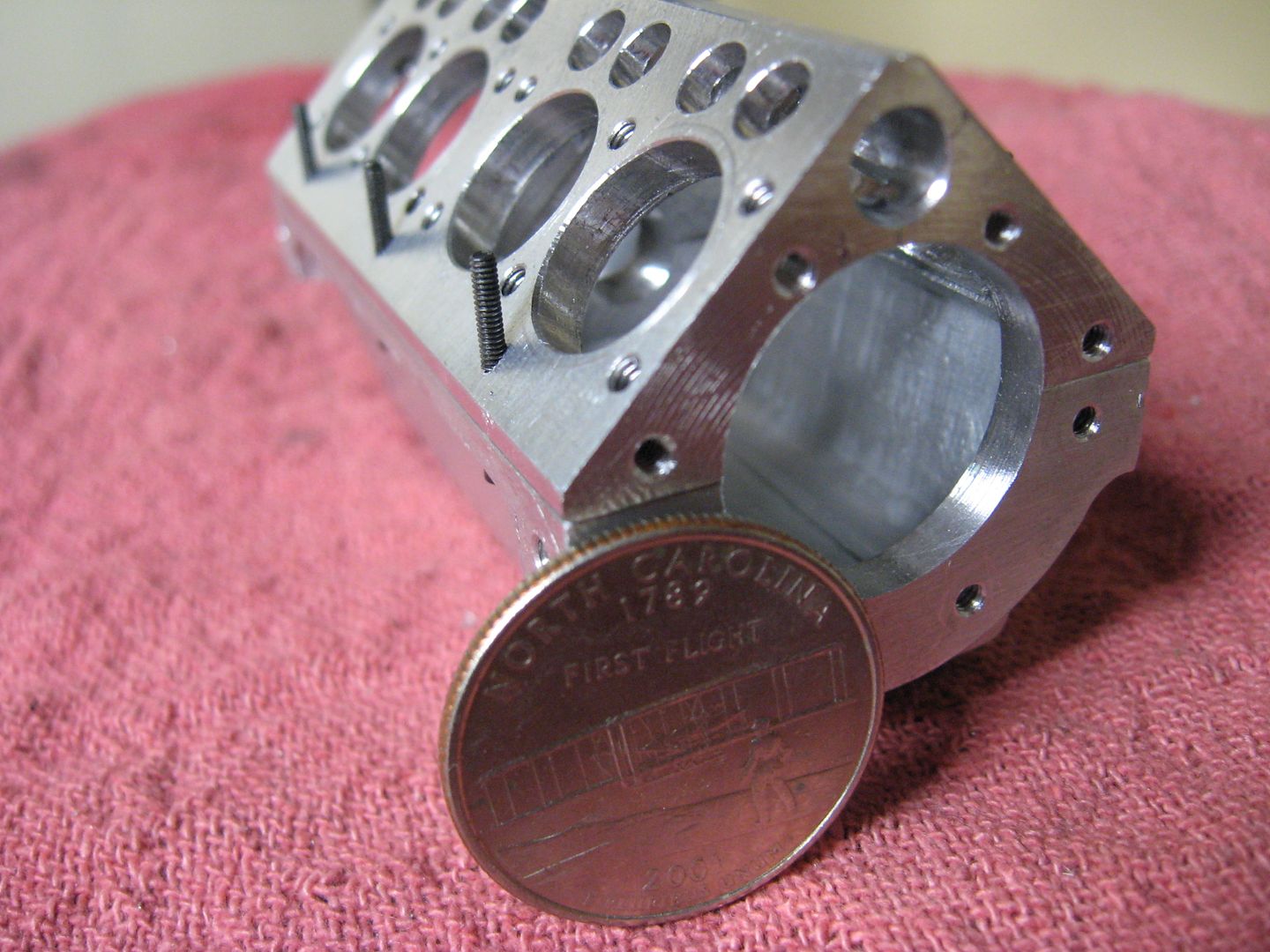

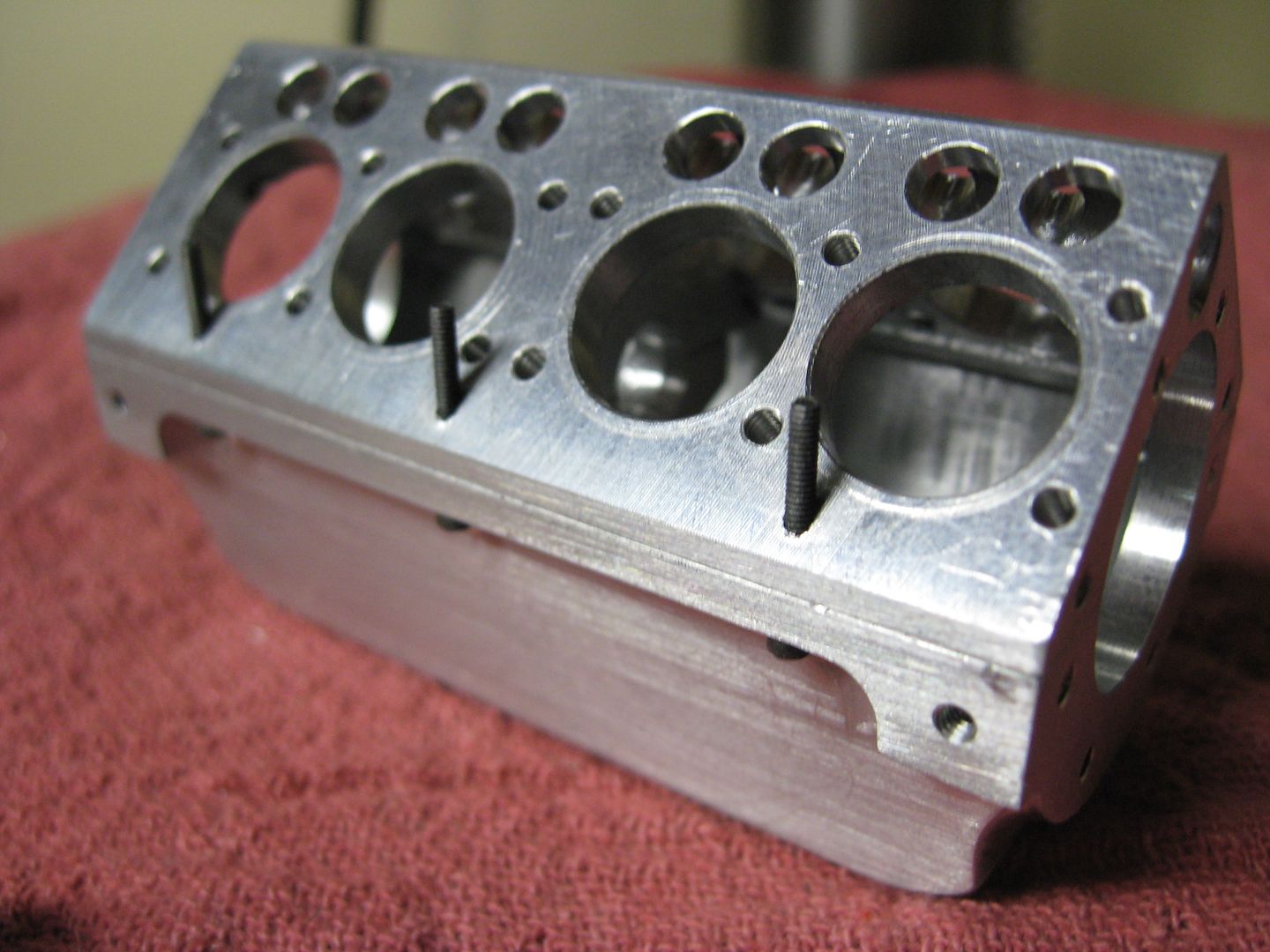

Well this is it for today. It was so nice to spend the whole day in the shop.

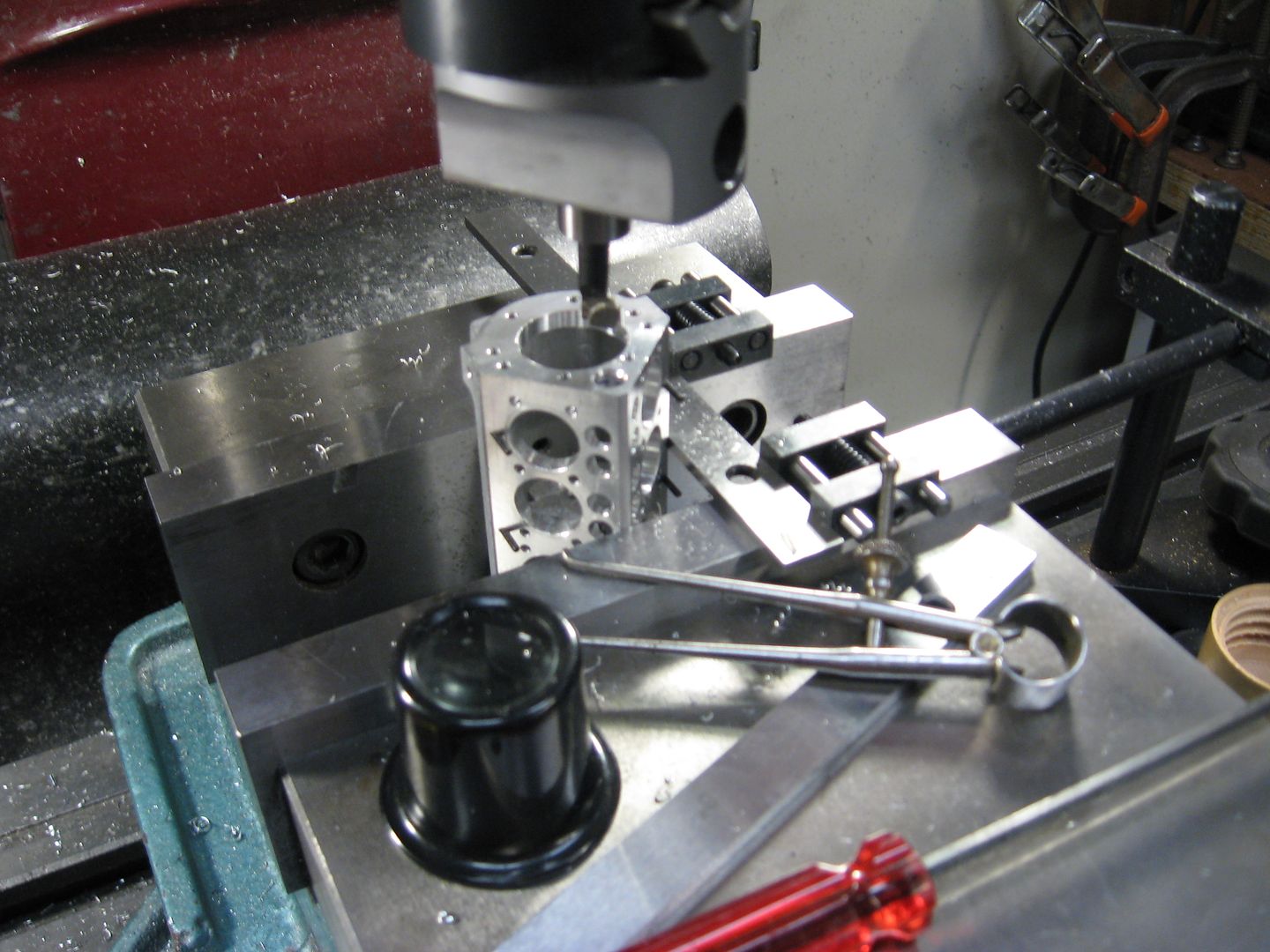

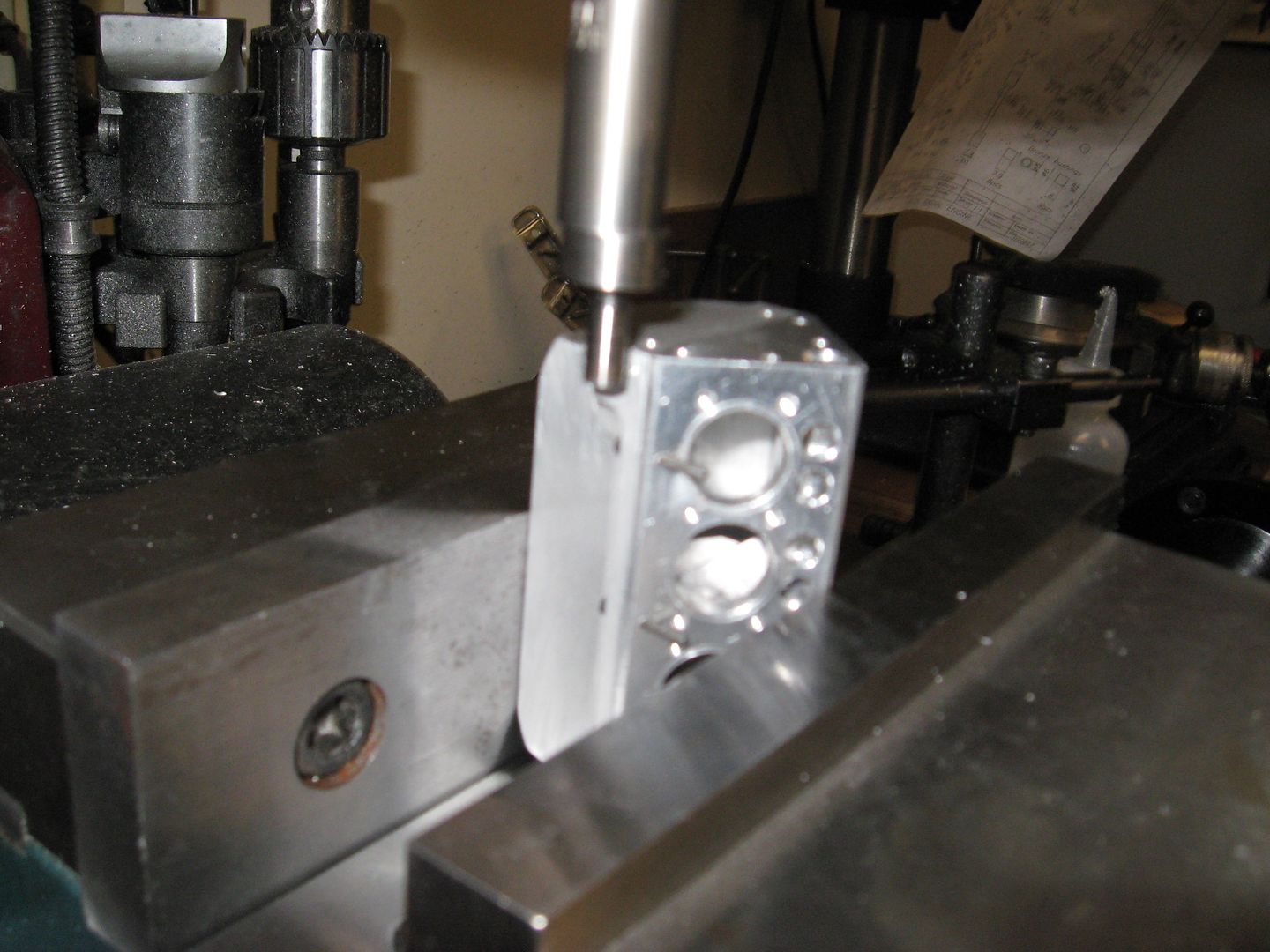

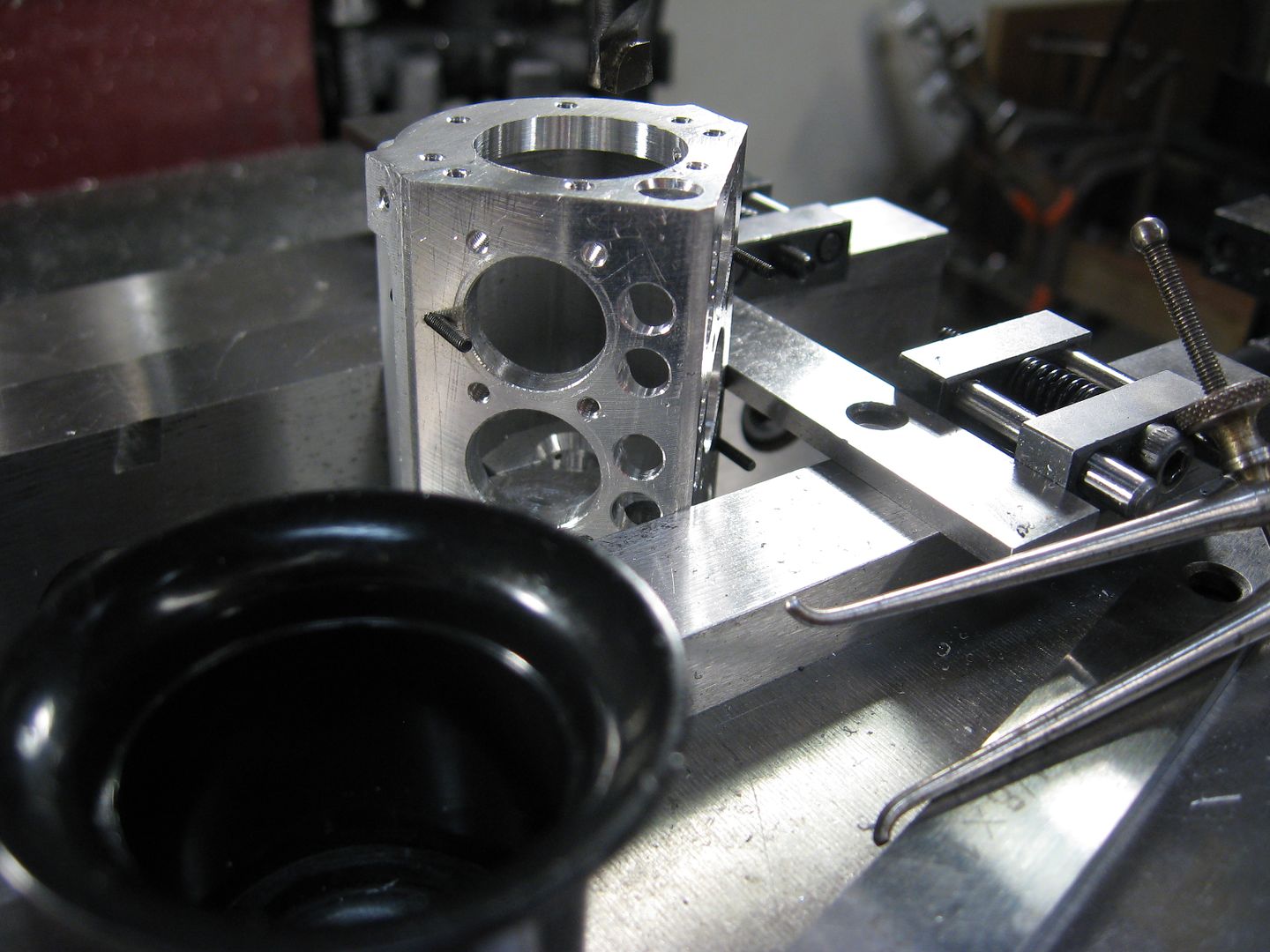

I bet you guys where saying Tony will be sweating bullets on this cut. Well you where wrong...I wasn't sweating bullets.......I was sweating canon shells :big:

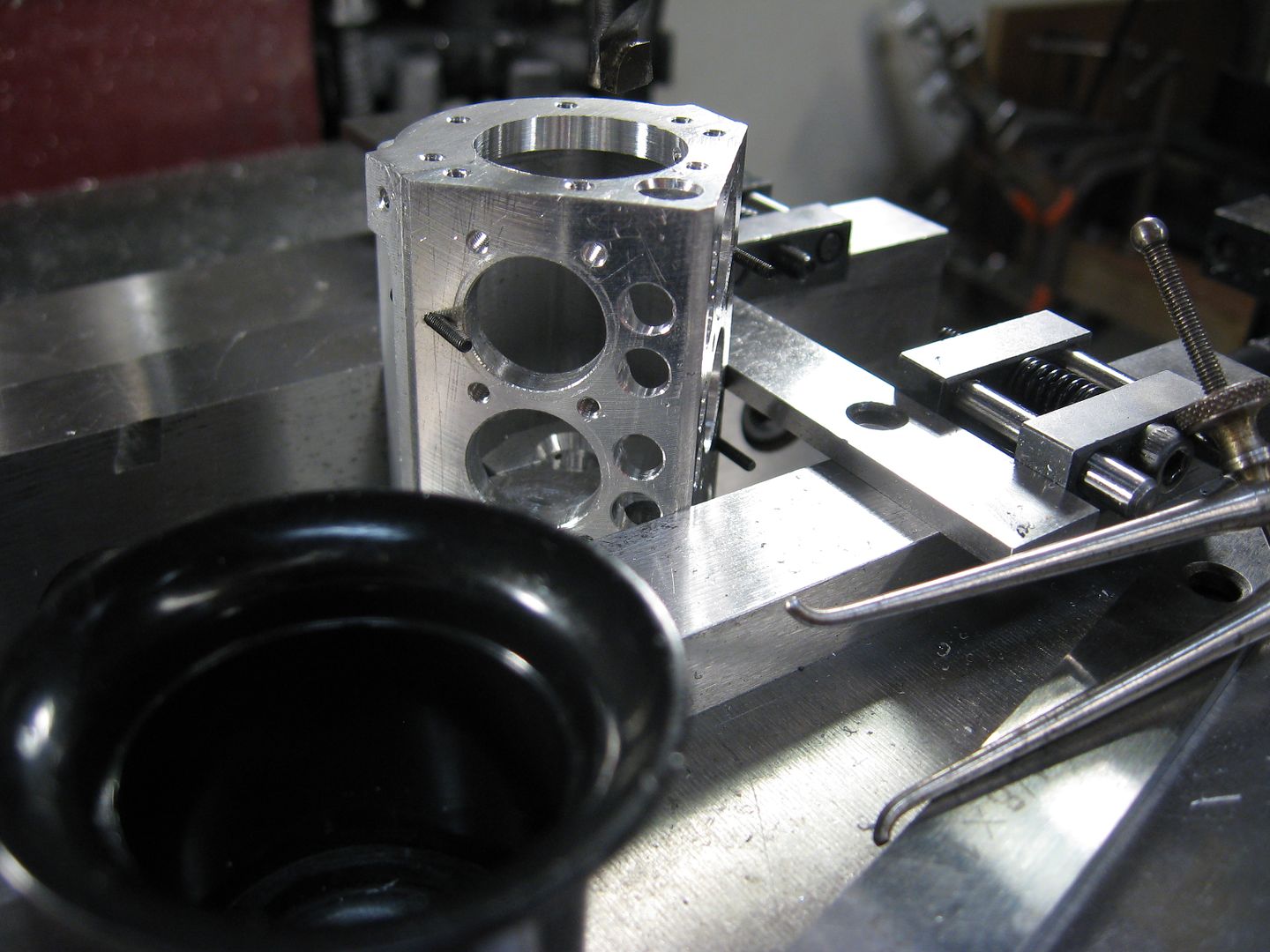

So far all looks good. I messaged the hole side to side with progressively larger end mills,

measuring and adjusting. All measures out within .0005

Fingers crossed for tomorrow when I turn it over.

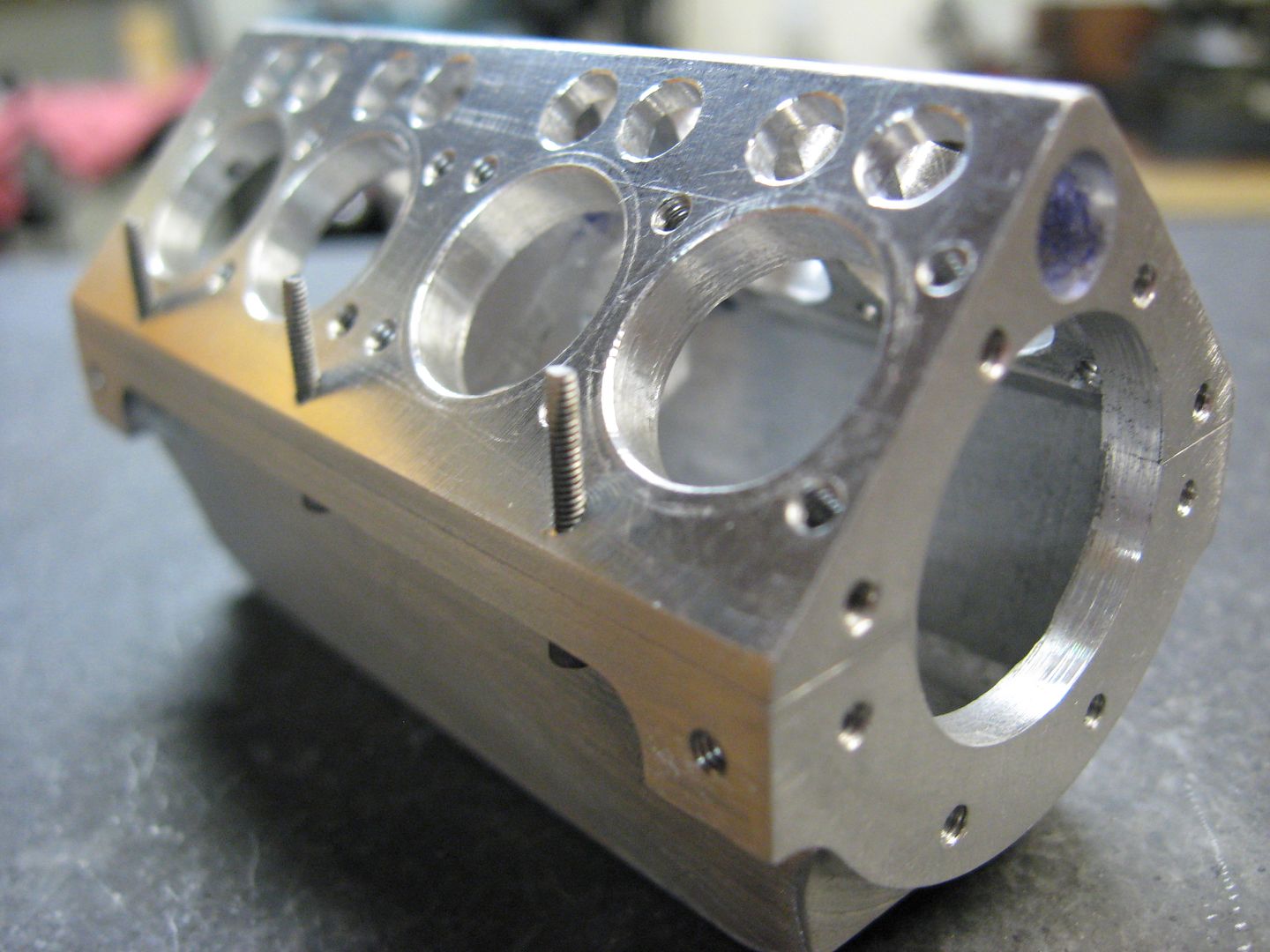

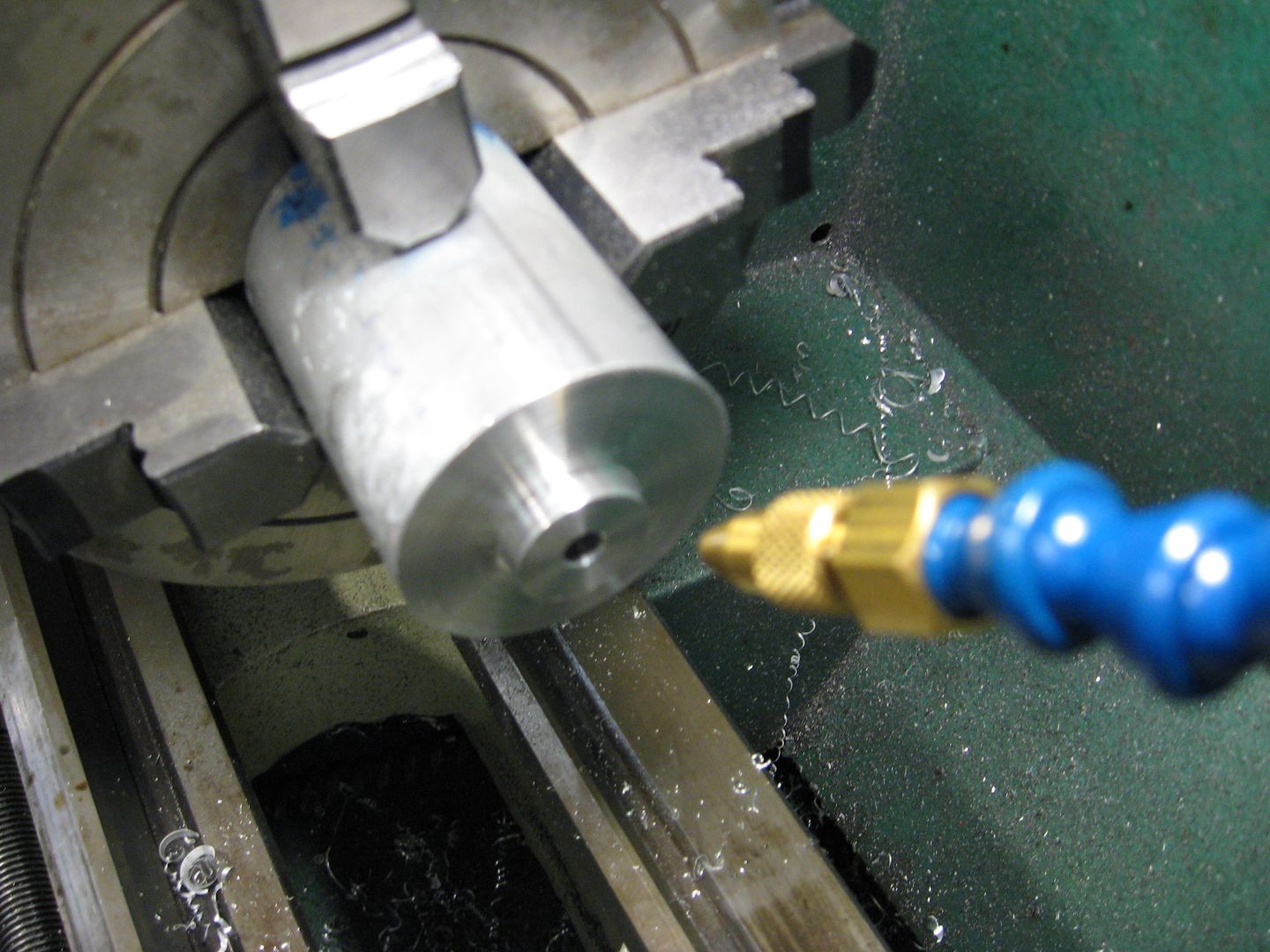

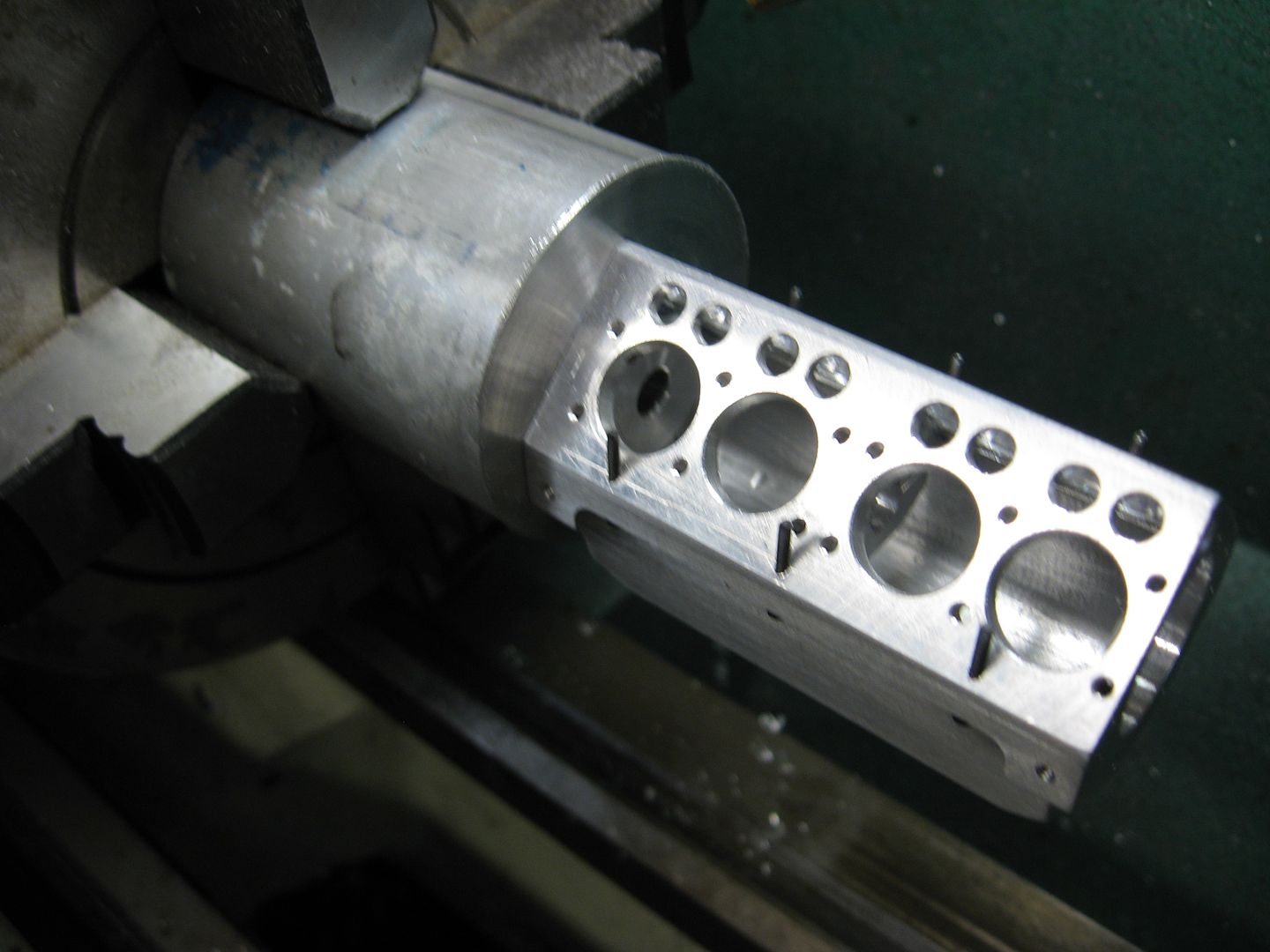

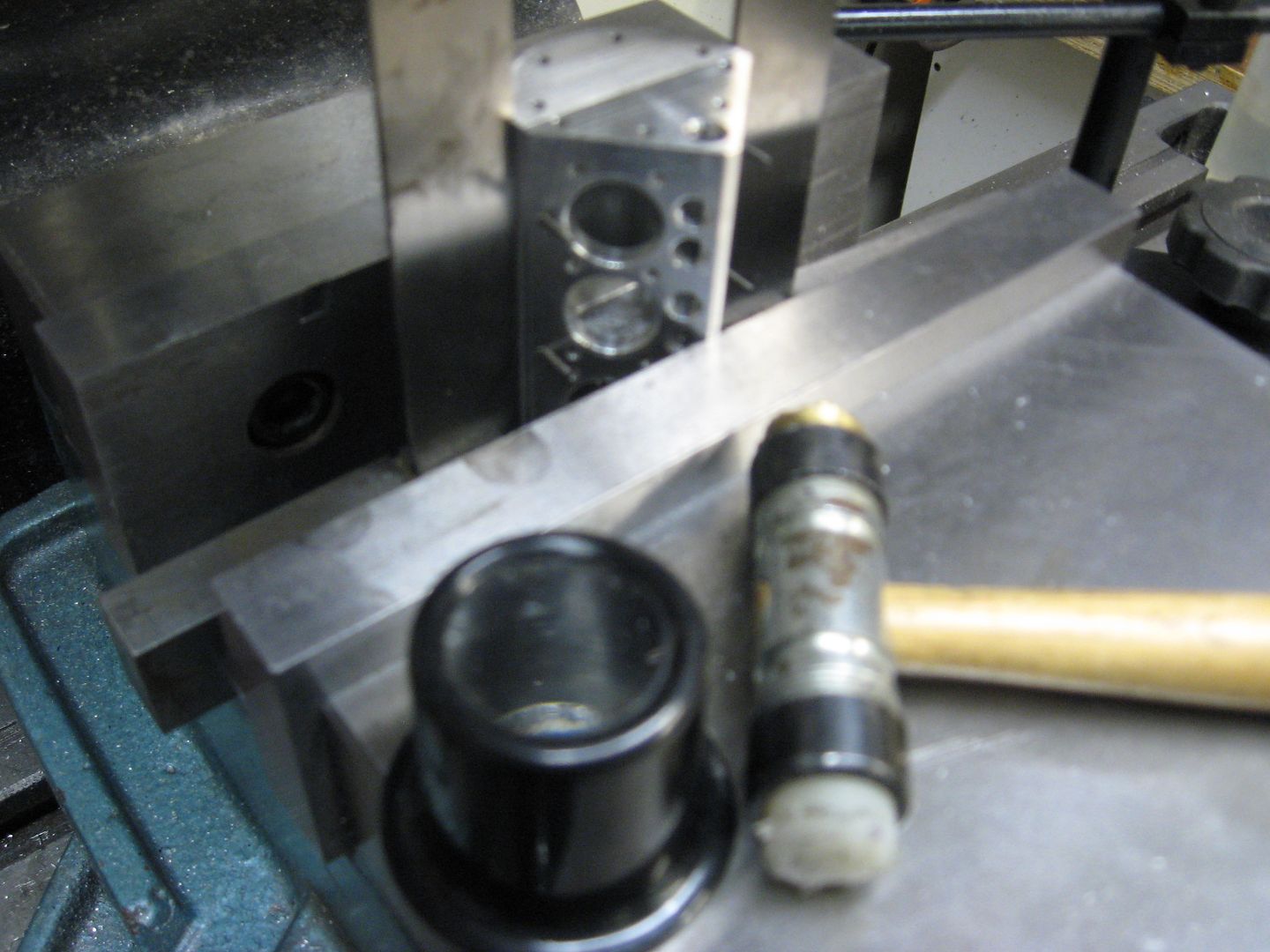

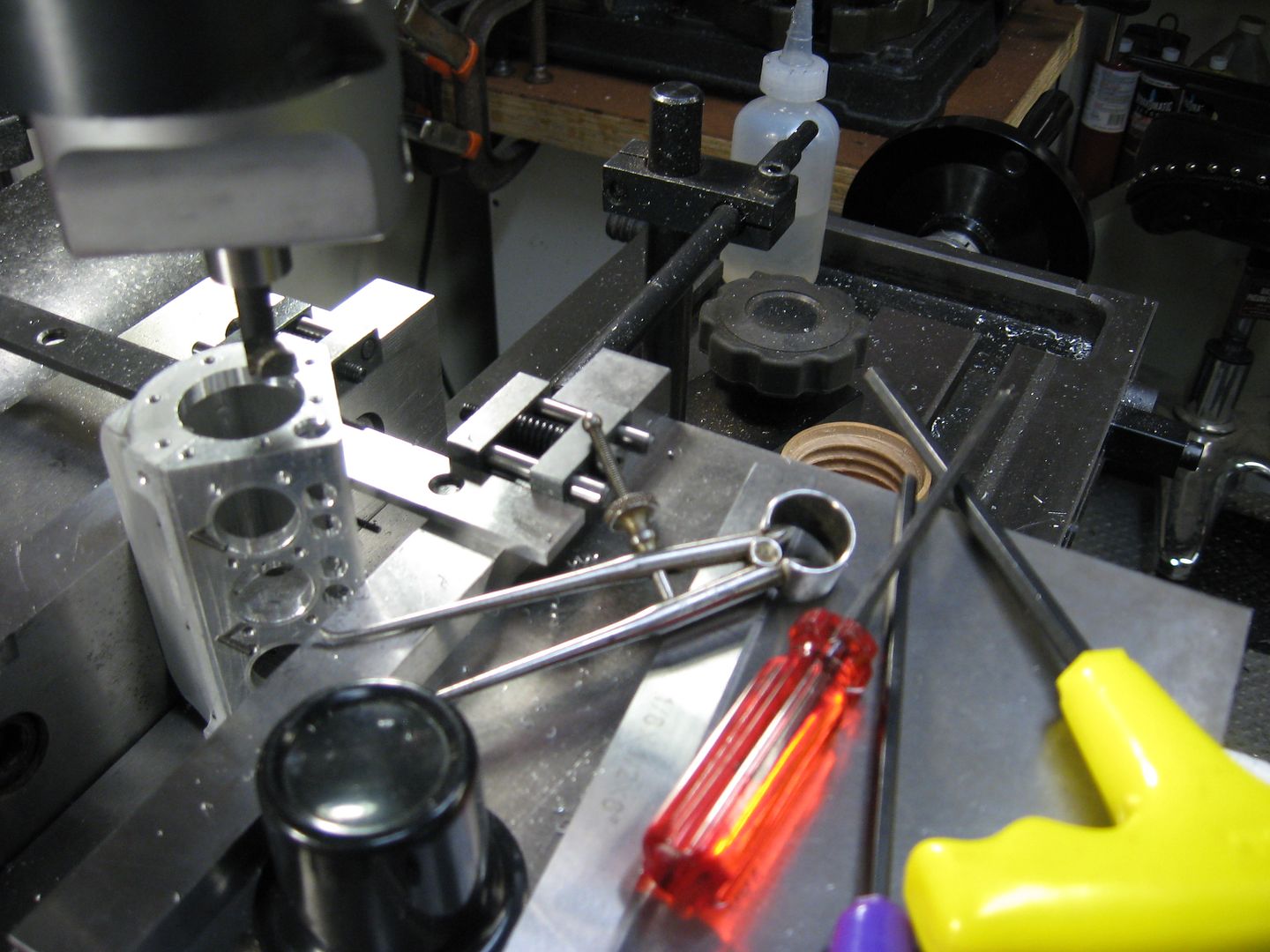

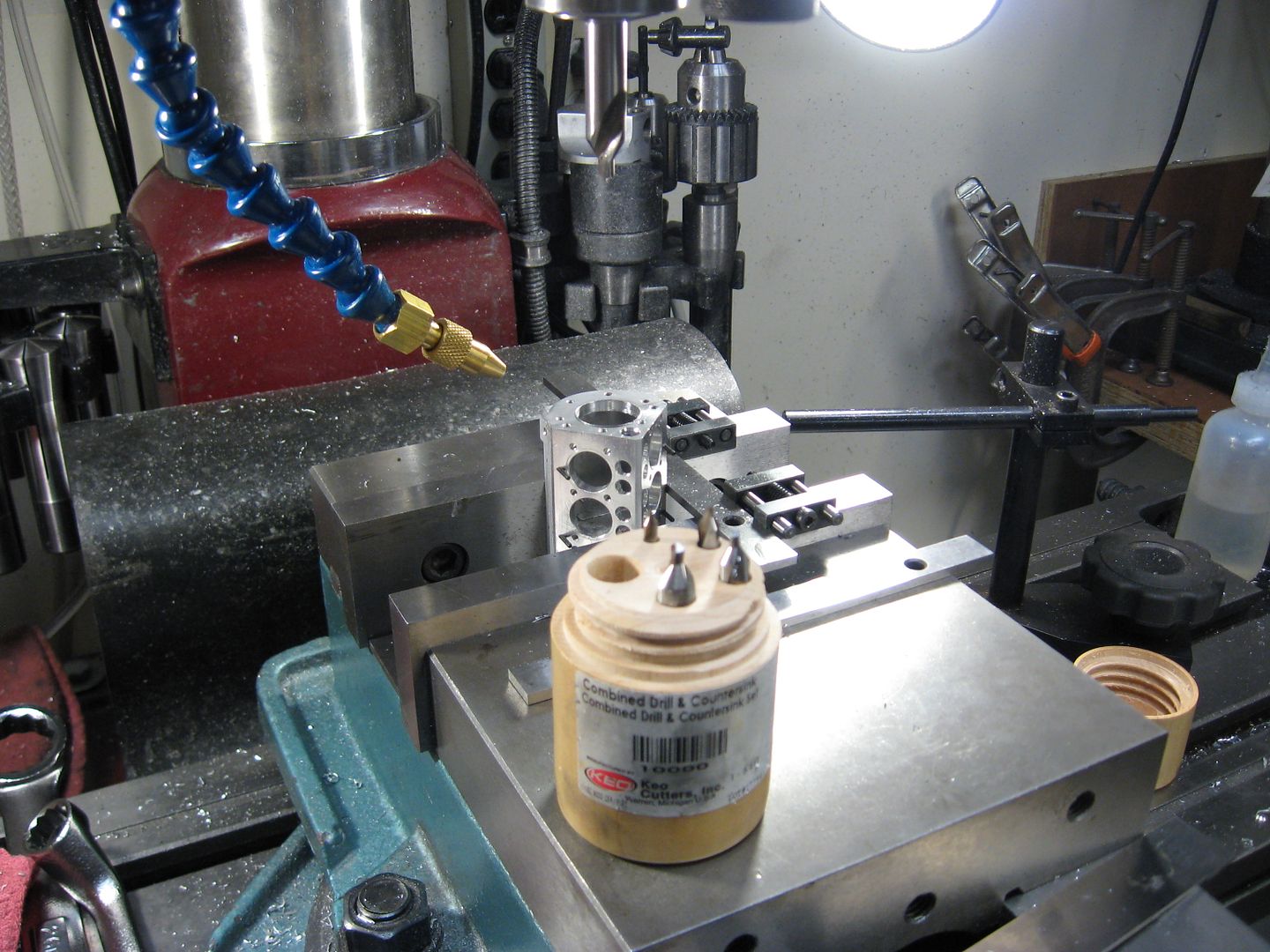

Set up...fine adjustment tool used to bring it home

I touched off to get me in the ball park

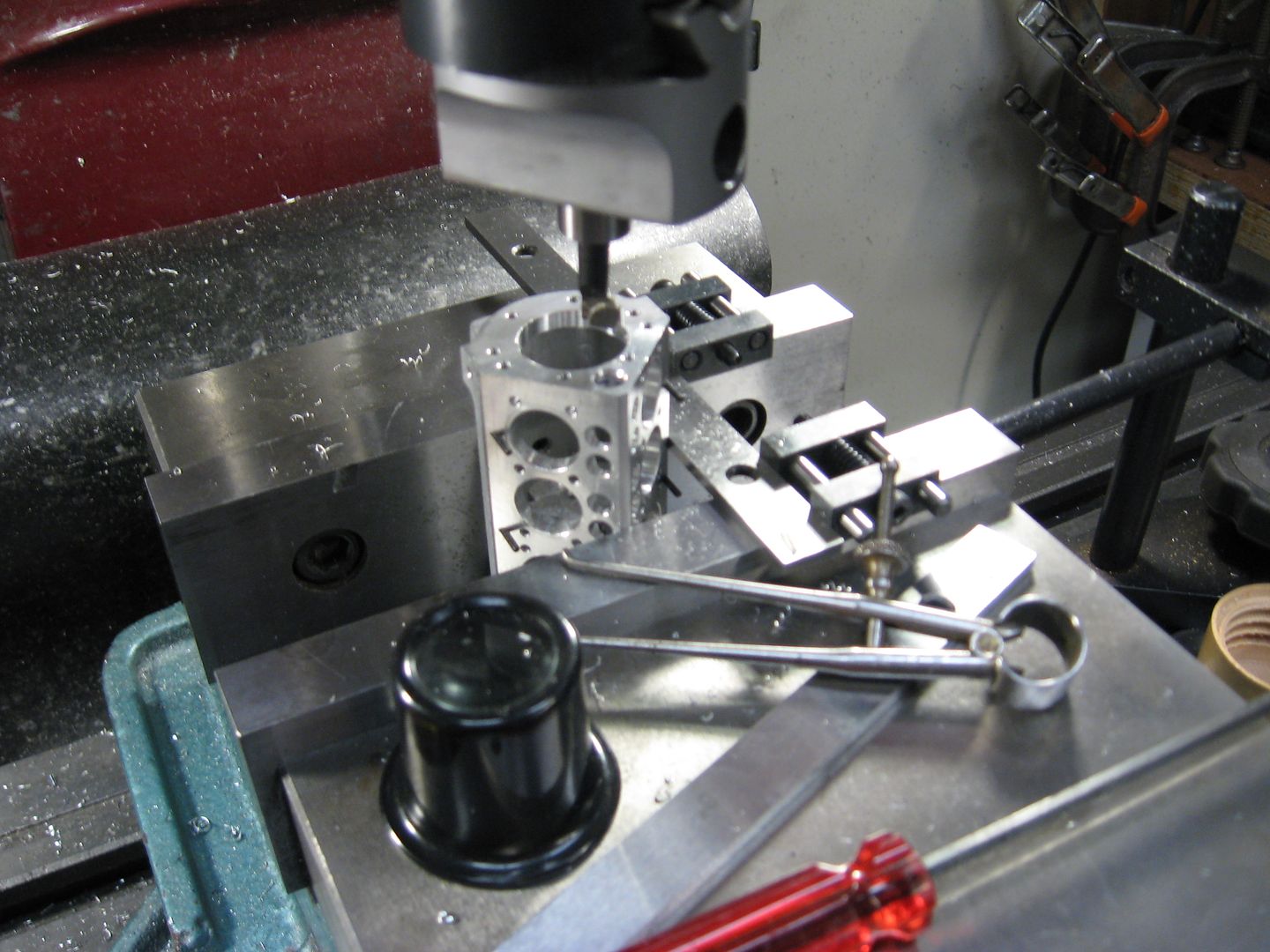

I kept measuring side to side to get it centered

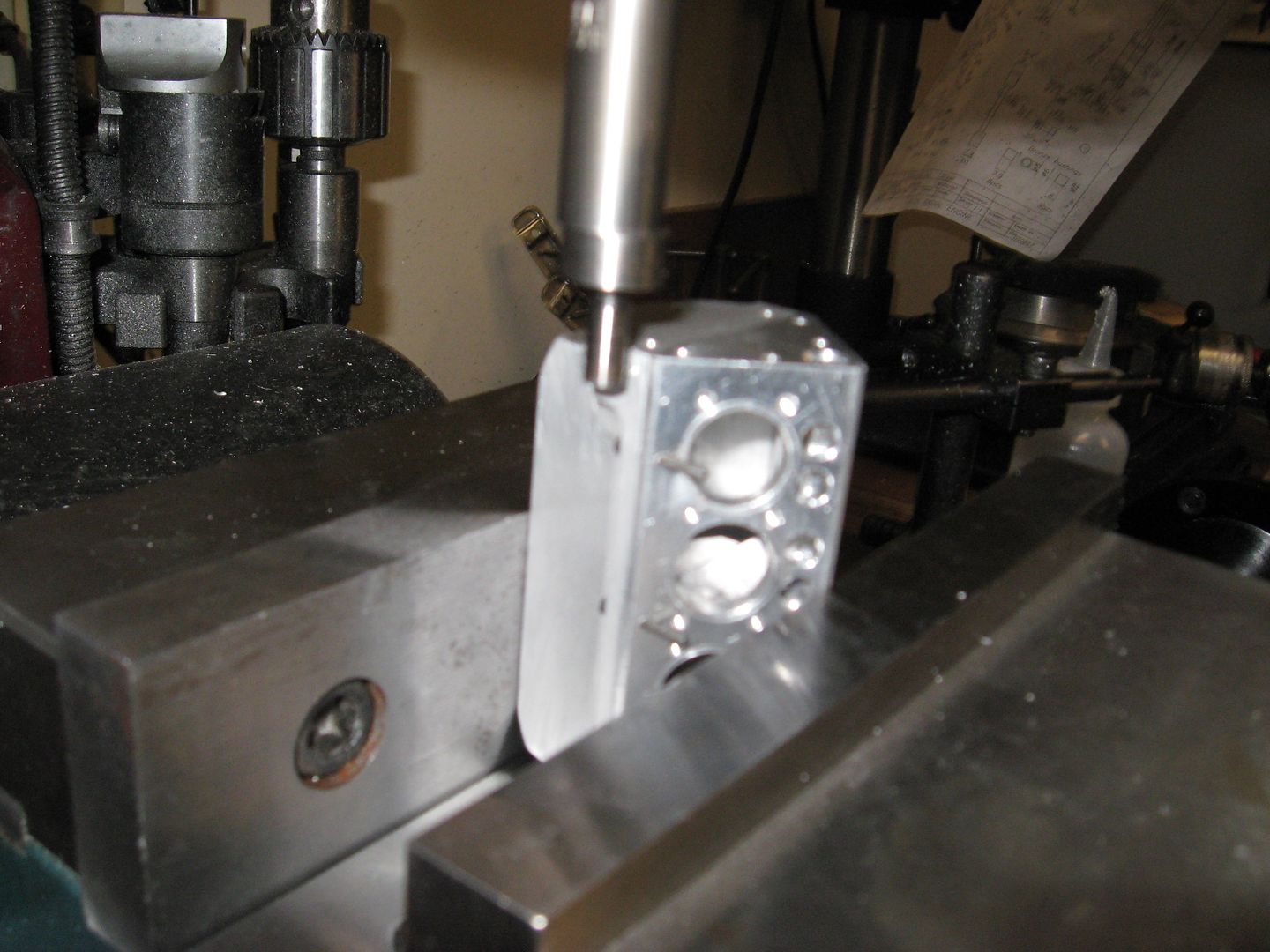

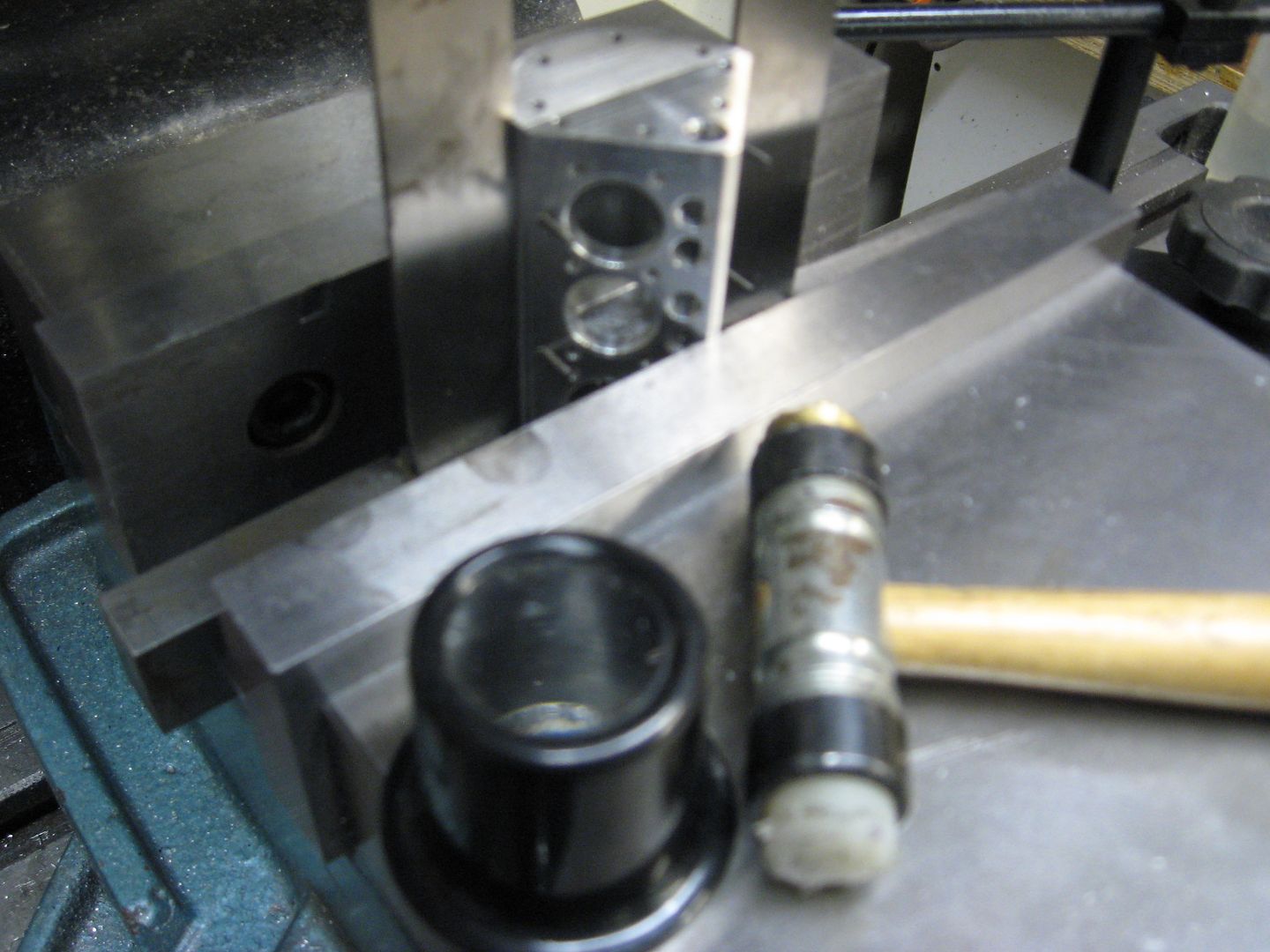

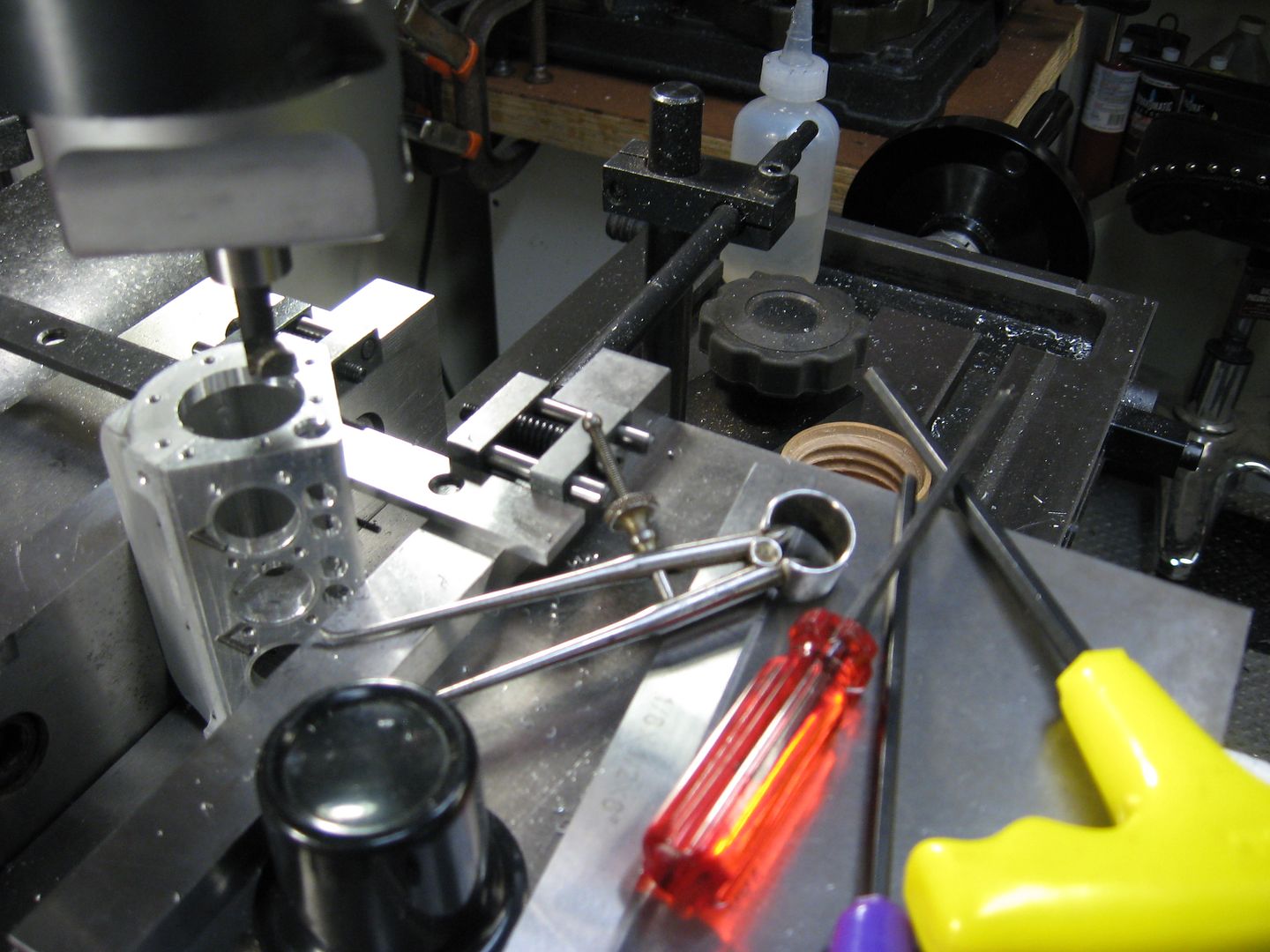

Centered drilled to the cap

Time for the bore

A boring job done!

Tomorrow the other side.

Thanks for the peek

Tony

The way I drop parts with my fat fingers....they just might. scratch.gif where the heck could it have gone :shrug:

solver

Ahhhh it's calling your name to, I see.

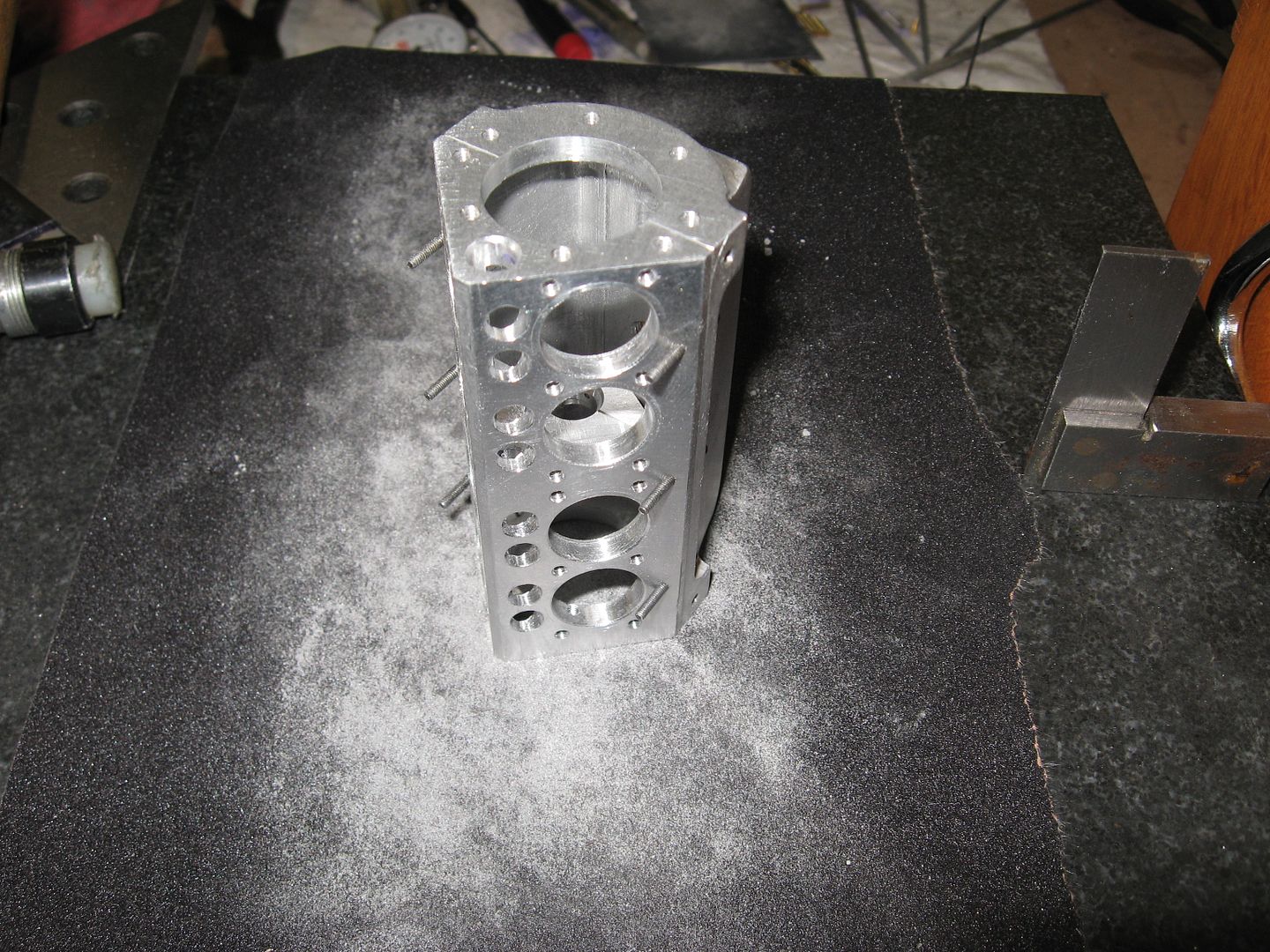

Well this is it for today. It was so nice to spend the whole day in the shop.

I bet you guys where saying Tony will be sweating bullets on this cut. Well you where wrong...I wasn't sweating bullets.......I was sweating canon shells :big:

So far all looks good. I messaged the hole side to side with progressively larger end mills,

measuring and adjusting. All measures out within .0005

Fingers crossed for tomorrow when I turn it over.

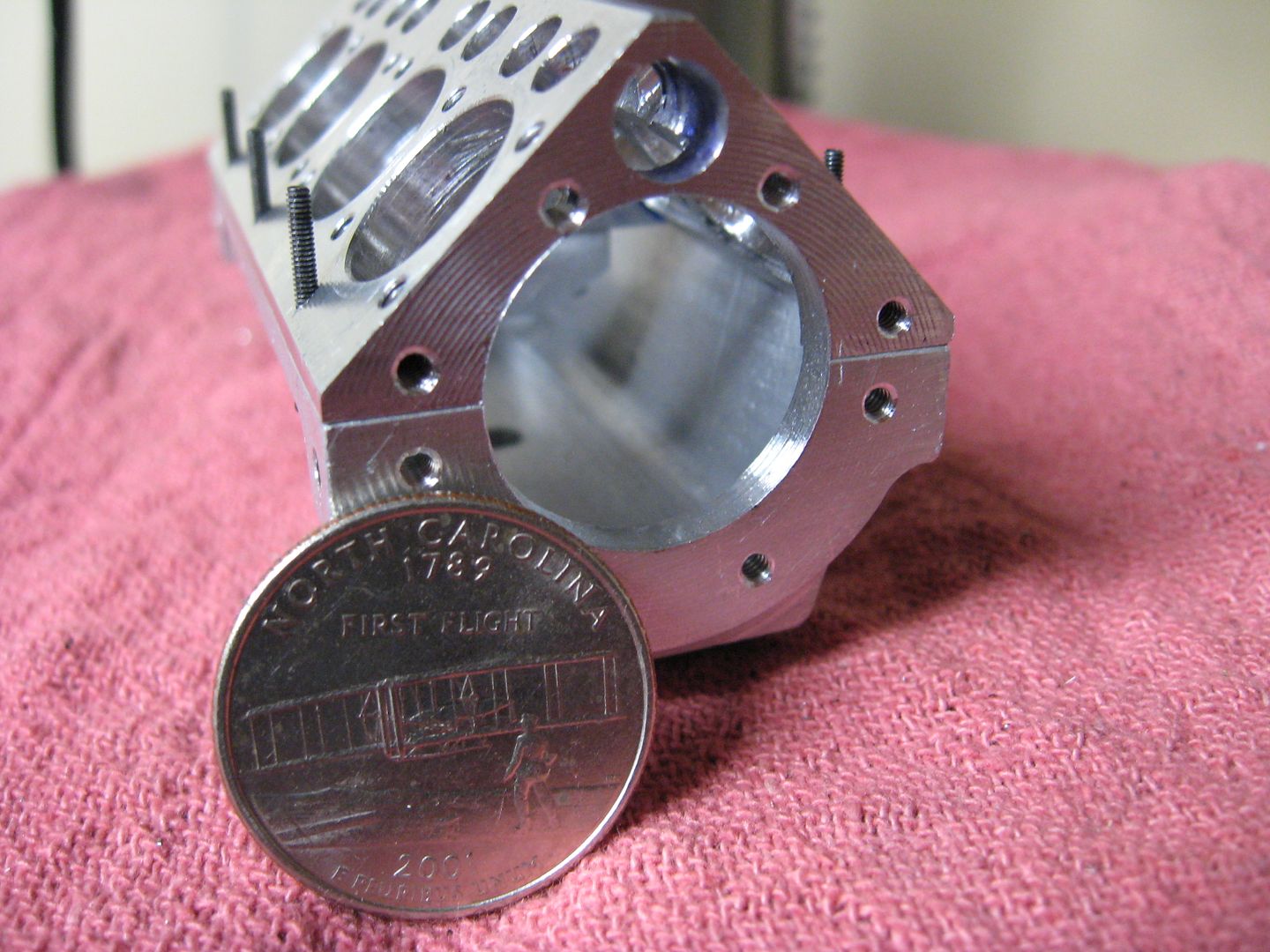

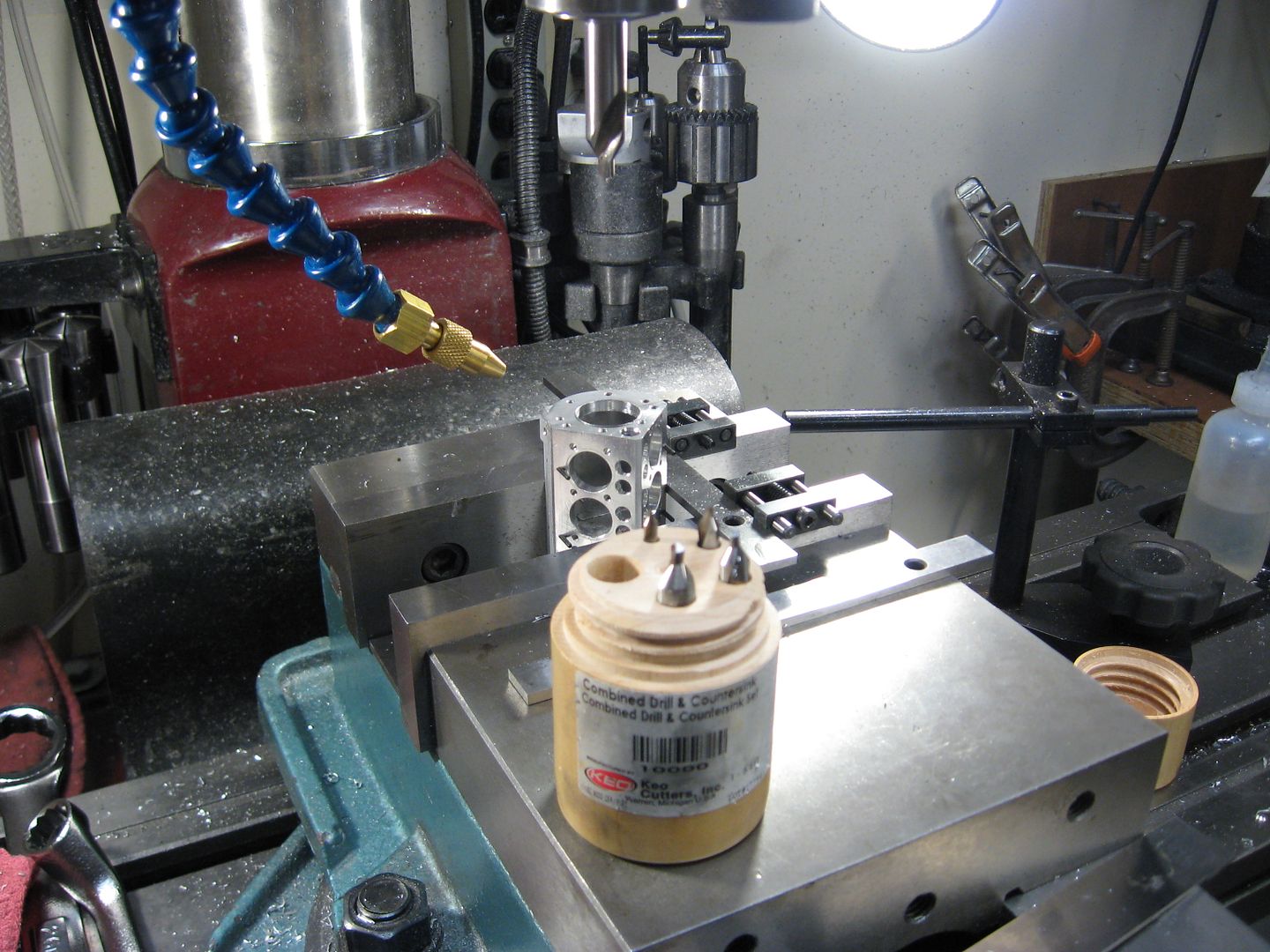

Set up...fine adjustment tool used to bring it home

I touched off to get me in the ball park

I kept measuring side to side to get it centered

Centered drilled to the cap

Time for the bore

A boring job done!

Tomorrow the other side.

Thanks for the peek

Tony