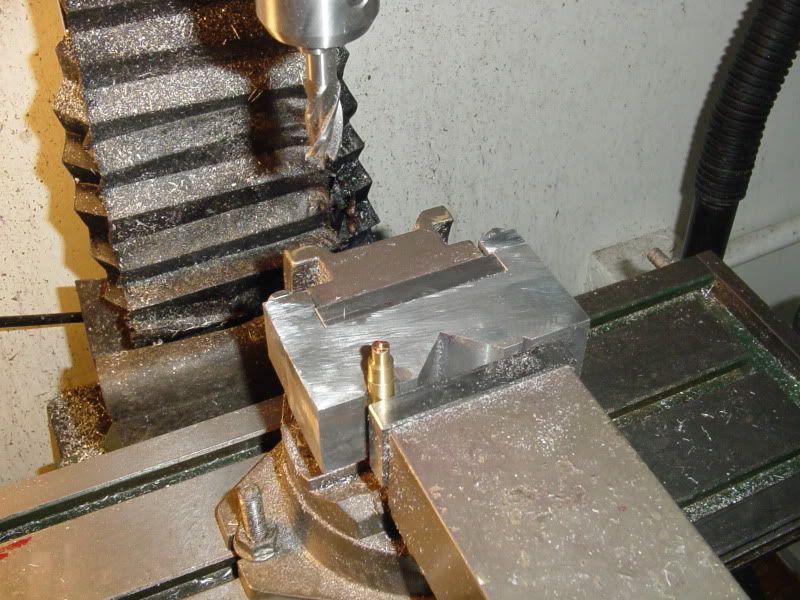

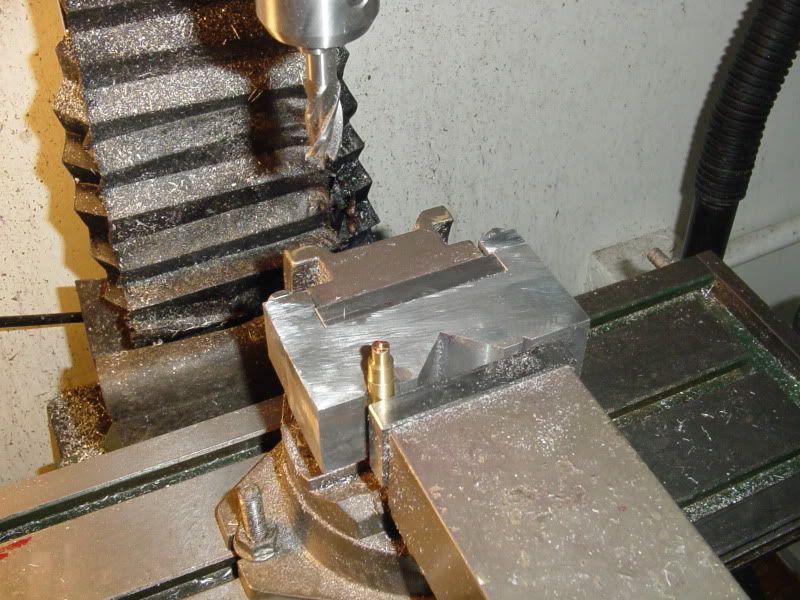

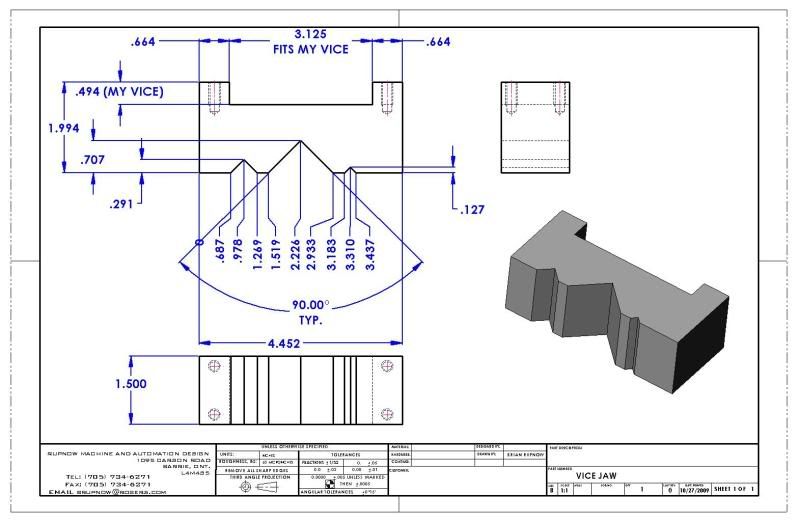

Every once in a (rare) while, I have to stand a round part on end in my mill and do "something" to the end of it.---And up untill today, I didn't have any real good way of holding onto a round part standing on end. I am still waiting for some "real work" to come into my engineering office, so today I decided to make a V-block that would fit into my Tilt-A-Whirl vice. I hate to admit it, but it took me the entire day to make this, and fortunately I had a peice of 2" thick scrap aluminum plate around. I designed the 3 V's to accomodate any diameter rod from 1/8" up to 1 1/4" diameter. I stuck a peice of 5/16" round brass in the fixture, just for "show and tell". The fixture is a "good fit" over the fixed jaw in my vice, and can be lifted off without having to tighten or loosen the bolts holding the rear clamp bars in place.