Holescreek

Well-Known Member

- Joined

- Jan 9, 2009

- Messages

- 91

- Reaction score

- 0

I did a search in the forum for " thread wires" and didn't get any hits so forgive me if this has been discussed already.

I have to make an odd sized tap to make some replacement parts for an old steady rest I am adapting to my lathe. The thread size is 7/16-10 LH (not ACME). While I was out there finishing the threading portion I remembered all the times I have heard coworkers complain that they didn't like using thread wires because they are too hard to hold while measuring. I thought this might be a useful tip for anyone that is curious about using thread wires.

Thread wires are cheap. For $12 they are the cheapest tool you can buy to measure threads for size (pitch diameter).

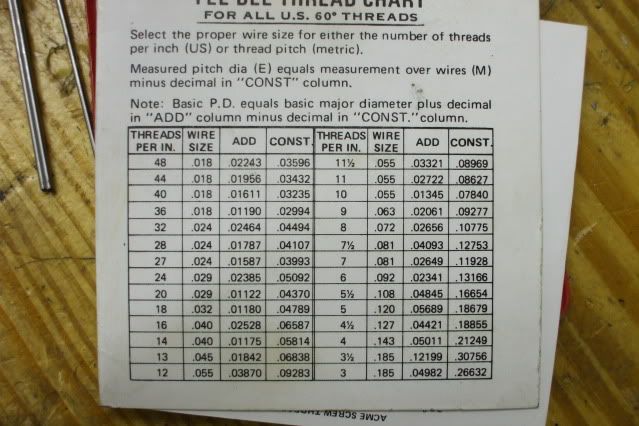

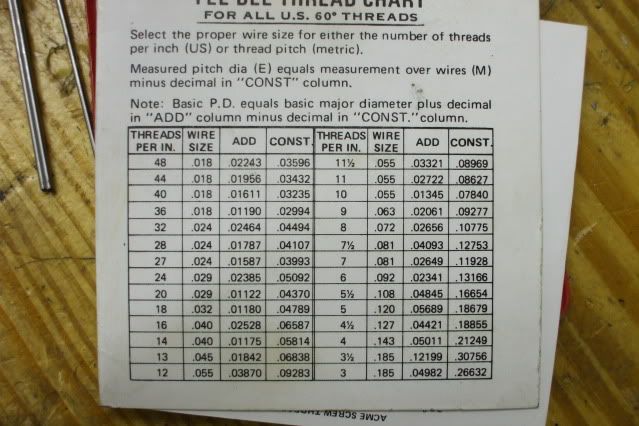

Each set contains several sizes of wires in matched sets of 3 wires each and a chart which tells you what size wire set to use for the pitch of the thread you want to measure ie 10-32 = 32 pitch. The chart also ists an "add" and "constant" number for each pitch/wire combination.

The way thread wires are used is to place 2 wires on one side of the thread and a single wire on the other side of the thread and measure over the wires with a micrometer. The "trick" is to hold all those wires in place while you fumble with a micrometer to get the measurement. Good luck finding those wires in your chip pan! I wrap tape around 2 wires then leave a bit hanging off to attach to the third wire.

With this setup you can place the wires into the V of the thread and hold them there by pinching the loose end. This leaves a hand free to measure with.

I have to make an odd sized tap to make some replacement parts for an old steady rest I am adapting to my lathe. The thread size is 7/16-10 LH (not ACME). While I was out there finishing the threading portion I remembered all the times I have heard coworkers complain that they didn't like using thread wires because they are too hard to hold while measuring. I thought this might be a useful tip for anyone that is curious about using thread wires.

Thread wires are cheap. For $12 they are the cheapest tool you can buy to measure threads for size (pitch diameter).

Each set contains several sizes of wires in matched sets of 3 wires each and a chart which tells you what size wire set to use for the pitch of the thread you want to measure ie 10-32 = 32 pitch. The chart also ists an "add" and "constant" number for each pitch/wire combination.

The way thread wires are used is to place 2 wires on one side of the thread and a single wire on the other side of the thread and measure over the wires with a micrometer. The "trick" is to hold all those wires in place while you fumble with a micrometer to get the measurement. Good luck finding those wires in your chip pan! I wrap tape around 2 wires then leave a bit hanging off to attach to the third wire.

With this setup you can place the wires into the V of the thread and hold them there by pinching the loose end. This leaves a hand free to measure with.