You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Upshur Farm Engine Builders

- Thread starter mocaquita

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Hello DaveB,

I have built a few Upshur Designs over the past 15 years, and have seen many more at shows over that time. No two were exactly alike!!! It seems that everyone does some modifying to the plans. Two things that helped me were to use a standard DOM steel pipe for the cylinder sleeve . I got one with a .750 ID, and made the rest of the cylinder to fit around it. I also have used both O Rings and cast iron rings, and the CI holds up better. The other was to use the more complicated style of carburetor with the drawings. It took a little longer to build, but worked much better than the simple tube. Good luck with the engine.

ART

I have built a few Upshur Designs over the past 15 years, and have seen many more at shows over that time. No two were exactly alike!!! It seems that everyone does some modifying to the plans. Two things that helped me were to use a standard DOM steel pipe for the cylinder sleeve . I got one with a .750 ID, and made the rest of the cylinder to fit around it. I also have used both O Rings and cast iron rings, and the CI holds up better. The other was to use the more complicated style of carburetor with the drawings. It took a little longer to build, but worked much better than the simple tube. Good luck with the engine.

ART

Thanks Art for replying! I was beginning to think no one here builds Upshur designs! I think I am going with a horizontal "F" head. I'll basically follow the design except for pinned valve retainers, cast flywheels, a commercial set of points, and perhaps a RC engine carb. I think I'll try the throttle carburetor as you suggest first. Thanks for the tips on the rings and and DOM tubing.

Dave

Dave

- Joined

- Aug 8, 2009

- Messages

- 930

- Reaction score

- 12

A month or so ago I bought the plans from Helen for this engine. I'm waiting for my machining skills to develop a little more before I tackle this one. I was hoping you'd get a few more responses so I can reference them when the time comes. Could be you'll be one of the pioneers for this build, at least on this forum. Care to start a build thread?

-Trout

-Trout

rudydubya

Well-Known Member

- Joined

- Nov 26, 2008

- Messages

- 337

- Reaction score

- 7

Dave, sorry I didn't respond to your post earlier, I've been out of town. I built the Upshur horizontal with the air cooled cylinder option last year as my first engine project. That's it in my avatar. I essentially learned how to use my 7X12 lathe while building it. I didn't have a mill until I was almost finished, so I did most of the drilling with my drill press.

More pictures of it here http://www.homemodelenginemachinist.com/index.php?topic=4704.0

and here http://www.homemodelenginemachinist.com/index.php?topic=4752.0

And videos of it running here http://www.homemodelenginemachinist.com/index.php?topic=4709.0

I followed the plans as closely as I could. The few changes I made during the initial build were because of oversights and mistakes. I went with the "O" ring option and made the spark plug and springs as described in the plans. I also went with the optional sparkplug location in the top instead of the side of the cylinder head. If I had it to do over again, I'd put it in the side of the head, easier to get to.

I started with the simple carburetor and breaker point ignition called out in the plans and got the engine running, but wasn't satisfied with the mechanical points, so I changed over to a Hall Effect transistorized ignition with a Rimfire plug from Jerry Howell. I like that combination much better. After I was satisfied with its performance, I tried the throttled carburetor option in the plans just to see how it worked, as shown on the long version video. It seemed to work as advertised.

After it was finished, I debated about building the hit and miss governor, thought it might be too complicated for me, but decided to try it anyway. Glad I did, I really like the hit and miss operation. I did have to modify the size and shape of the governor parts so they would fit between the gears and the flywheel, since I mistakenly put the crankshaft journal right in the center of the shaft, instead of offsetting it to one side to allow for more room on the governor side as called out in the plans. I use the simple carburetor now with the hit and miss governor.

The build went well, considering my inexperience. I found the plans to be complete and relatively easy to follow and I didn't find any errors.

Hope this helps.

Regards,

Rudy

More pictures of it here http://www.homemodelenginemachinist.com/index.php?topic=4704.0

and here http://www.homemodelenginemachinist.com/index.php?topic=4752.0

And videos of it running here http://www.homemodelenginemachinist.com/index.php?topic=4709.0

I followed the plans as closely as I could. The few changes I made during the initial build were because of oversights and mistakes. I went with the "O" ring option and made the spark plug and springs as described in the plans. I also went with the optional sparkplug location in the top instead of the side of the cylinder head. If I had it to do over again, I'd put it in the side of the head, easier to get to.

I started with the simple carburetor and breaker point ignition called out in the plans and got the engine running, but wasn't satisfied with the mechanical points, so I changed over to a Hall Effect transistorized ignition with a Rimfire plug from Jerry Howell. I like that combination much better. After I was satisfied with its performance, I tried the throttled carburetor option in the plans just to see how it worked, as shown on the long version video. It seemed to work as advertised.

After it was finished, I debated about building the hit and miss governor, thought it might be too complicated for me, but decided to try it anyway. Glad I did, I really like the hit and miss operation. I did have to modify the size and shape of the governor parts so they would fit between the gears and the flywheel, since I mistakenly put the crankshaft journal right in the center of the shaft, instead of offsetting it to one side to allow for more room on the governor side as called out in the plans. I use the simple carburetor now with the hit and miss governor.

The build went well, considering my inexperience. I found the plans to be complete and relatively easy to follow and I didn't find any errors.

Hope this helps.

Regards,

Rudy

Hi,

Thanks Rudy for your information and tips on your Upshur build! I found your video very interesting and think your engine runs very well! I am impressed with how well it runs with the Upshur plan carburetors. You should be quite proud!

Trout-

Hope you have fun building an Upshur also! I am in the process of gathering information and materials now, and hope to build it next winter. Long ways away, but I am extremely busy in the summer and especially fall.

Thanks,

Dave

Thanks Rudy for your information and tips on your Upshur build! I found your video very interesting and think your engine runs very well! I am impressed with how well it runs with the Upshur plan carburetors. You should be quite proud!

Trout-

Hope you have fun building an Upshur also! I am in the process of gathering information and materials now, and hope to build it next winter. Long ways away, but I am extremely busy in the summer and especially fall.

Thanks,

Dave

rudydubya

Well-Known Member

- Joined

- Nov 26, 2008

- Messages

- 337

- Reaction score

- 7

Stew, I don't know how much you know about these little IC engines, so forgive me if I'm too elementary or go into too much detail here. But maybe those who've never seen how these work will find this of value. And, I don't profess to know about all the different designs for hit-and-miss governors, so I'll just describe the one my Upshur.

The hit-and-miss governor works by holding the exhaust valve open while the engine coasts (the "miss" mode), and then allowing the exhaust valve to close normally so that the piston can create a suction on the intake stroke and draw in fuel when the engine needs to fire to get back up to speed again (the "hit" mode). The regulation of the hitting and missing is by a system of weights, springs and levers.

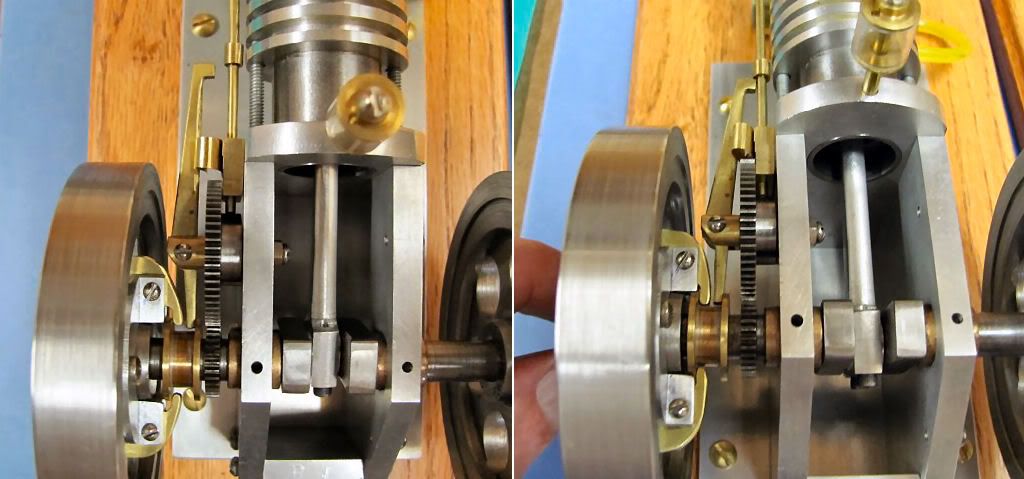

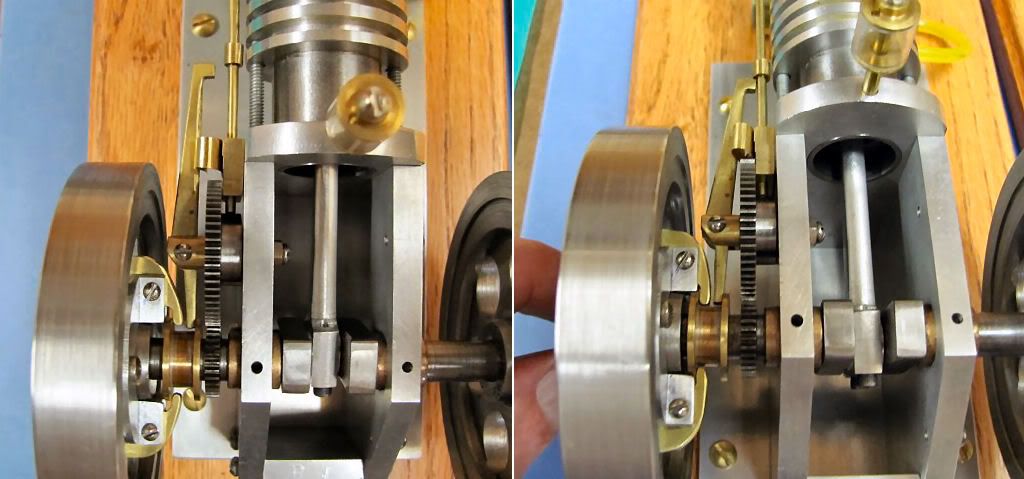

Those brass pieces on the outside of the flywheel with springs between them in the picture above act as weights and are on the ends of two arms that poke through a couple of the holes in the flywheel. Centrifugal force moves the weights away from the axle when flywheel speed increases and the springs pull them back toward the axle when the speed decreases.

In the pictures below, you can see how the arms are hinged on screws on the inside of the flywheel, so that as the weights are forced away from the axle, the arms push against the inside end of a spool and move it toward the flywheel. And, as the spool moves over toward the flywheel, it in turn forces another lever to swing over and interfere with a stop block on the exhaust valve pushrod, holding the valve open until the weights are pulled back toward the axle and the arms allow the spool to return away from the flywheel. On my Upshur, a small piece of brass sheet forward of the larger gear acts as a counterspring to hold the lever away from the pushrod when it's supposed to.

The picture on the left shows how the pushrod is free to act normally prior to a "hit" while the picture on the right shows how the pushrod is held in the open position after the hit, while coasting (my fingers are holding the weights apart, not squeezing them together).

I didn't make any provision to prevent the spark plug from firing during coast. Since there is no compression or fuel intake during coast, the plug still fires, but on an empty cylinder.

Dave, one additional item to your original question. If I did it again, I would definitely allow that extra room on the cam side of the crankshaft for a larger spool, one with two sections: one section for the weight arms and the other to capture the end of the pushrod stop lever, so I could eliminate the brass sheet spring. It took me a while to get that spring balanced with the weight springs for proper coasting. I don't think I've got it optimal yet.

Hope this helps.

Rudy

The hit-and-miss governor works by holding the exhaust valve open while the engine coasts (the "miss" mode), and then allowing the exhaust valve to close normally so that the piston can create a suction on the intake stroke and draw in fuel when the engine needs to fire to get back up to speed again (the "hit" mode). The regulation of the hitting and missing is by a system of weights, springs and levers.

Those brass pieces on the outside of the flywheel with springs between them in the picture above act as weights and are on the ends of two arms that poke through a couple of the holes in the flywheel. Centrifugal force moves the weights away from the axle when flywheel speed increases and the springs pull them back toward the axle when the speed decreases.

In the pictures below, you can see how the arms are hinged on screws on the inside of the flywheel, so that as the weights are forced away from the axle, the arms push against the inside end of a spool and move it toward the flywheel. And, as the spool moves over toward the flywheel, it in turn forces another lever to swing over and interfere with a stop block on the exhaust valve pushrod, holding the valve open until the weights are pulled back toward the axle and the arms allow the spool to return away from the flywheel. On my Upshur, a small piece of brass sheet forward of the larger gear acts as a counterspring to hold the lever away from the pushrod when it's supposed to.

The picture on the left shows how the pushrod is free to act normally prior to a "hit" while the picture on the right shows how the pushrod is held in the open position after the hit, while coasting (my fingers are holding the weights apart, not squeezing them together).

I didn't make any provision to prevent the spark plug from firing during coast. Since there is no compression or fuel intake during coast, the plug still fires, but on an empty cylinder.

Dave, one additional item to your original question. If I did it again, I would definitely allow that extra room on the cam side of the crankshaft for a larger spool, one with two sections: one section for the weight arms and the other to capture the end of the pushrod stop lever, so I could eliminate the brass sheet spring. It took me a while to get that spring balanced with the weight springs for proper coasting. I don't think I've got it optimal yet.

Hope this helps.

Rudy

- Joined

- Jan 17, 2009

- Messages

- 887

- Reaction score

- 81

Rudy

Thank you for the very comprehensive answer, I understand now. Farm type engines are very popular in the UK and events with a 1000 plus engines are held every summer, I have seen them running but its not easy to see wot's happening.

They were put to many uses at a shows one of the exhibitors had a laundry powered by an engine including the ironing.

Her's a link to an engine site that may be of interest to the guys lots of pics.

http://www.1000engines.co.uk/index.html

Thanks again

Stew

Thank you for the very comprehensive answer, I understand now. Farm type engines are very popular in the UK and events with a 1000 plus engines are held every summer, I have seen them running but its not easy to see wot's happening.

They were put to many uses at a shows one of the exhibitors had a laundry powered by an engine including the ironing.

Her's a link to an engine site that may be of interest to the guys lots of pics.

http://www.1000engines.co.uk/index.html

Thanks again

Stew

That was a very good explanation of the hit and miss cycle Rudy. I have an additional comment which probally applies to all engines of this type. When the engine cycles in the "miss" mode, and the exhaust valve is held open, cool air is drawn into the cylinder. With this happening for several revolutions the cylinder remains relatively cool. The reststance on your governor springs will contribute to this. My "air cooled" vertical Upsur will run out of fuel after a long running time, and the cylinder is not very hot without any additional cooling fan.

ART

ART

Similar threads

- Replies

- 7

- Views

- 1K