macona

Well-Known Member

- Joined

- Sep 20, 2007

- Messages

- 112

- Reaction score

- 3

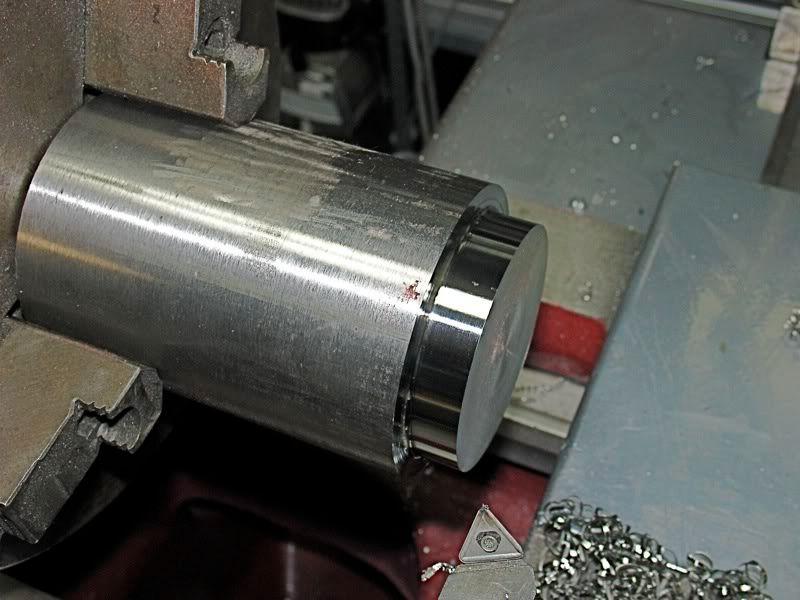

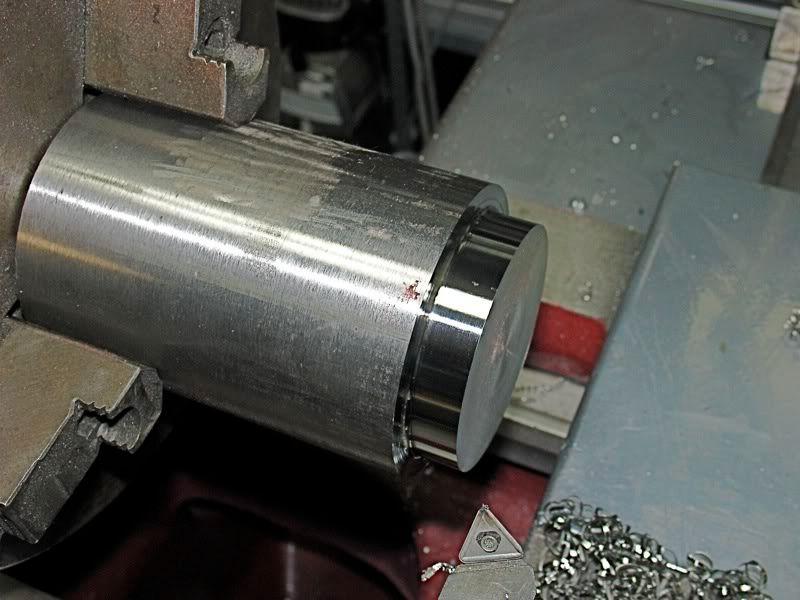

Heres a pic of a small piece of titanium I was turning the other day. 3" dia 5" long. In my 8" 3jaw. About 300RPM heavy feed and .1" off the dia per pass.

Titanium actually machines rather easily. Main things are you run slow (Ti has horrible heat transfer) heavy feeds and dont stop. Stopping with the tool rubbing will instantly work harden the Ti.

Also the more rigid the machine the better.

Titanium actually machines rather easily. Main things are you run slow (Ti has horrible heat transfer) heavy feeds and dont stop. Stopping with the tool rubbing will instantly work harden the Ti.

Also the more rigid the machine the better.