;D

Hi Bob,

Now that is looking more like it. ;D ;D 8)

No need to feel in debt my friend, I am most pleased to assist in your quest. After all, that is what this site is all about.

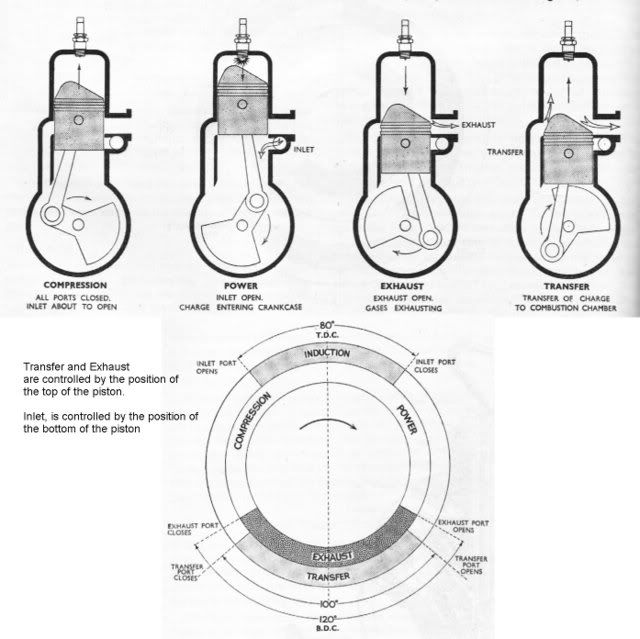

Looking at your original and revised timing diagrams, I can understand the change to the INLET timing

. that makes perfect sense given the larger port opening.

What I dont understand though is why the exhaust, transfer, and sub-piston induction timing have changed

. (Unless you have changed the piston geometry or something else).

The revised transfer port PCD location/angles should not have changed the opening/closing position/angles

the steeper entry (drilling) angle was primarily to give more crankcase-sealing surface under the exhaust flange but the top of the port (in the cylinder wall) should still remain in its original location.

The other advantage of the steeper angle is that the fresh (incoming) charge will be directed more towards the top of the cylinder

and away from the open exhaust ports

. Thus helping to purge any remaining spent gasses.

Since I can see no dimension changes to the exhaust port, either in location or height from the crankshaft centre and the exhaust port remains the same 0.2890 I am at a loss as to why the exhaust timing has changed.

Just as with the TRANSFER ports timing, given the same port location, this/these would be determined by the top edge of the piston.

Similarly, the same goes for the sub-piston induction, since the bottom of the piston relative to the exhaust port determines this.

HAVE you changed the piston dimensions?

or perhaps the con-rod length?, or the location of the gudgeon pin (wrist pin) in the piston relative to its length?

DAH!!!

.. WHAT GIVES on this?????? :-\ :-\

The overlap between the INLET opening and TRANSFER closing IS a problem

.. Especially since the EXHAUST ports are also still OPEN.

This will allow the inlet to suck some of the fresh charge and/or some fresh air (via the open exhaust ports) back into the crankcase and reduce the draw through the carb

. Leading to a weaker charge in the crankcase for the next cycle.

This, however, can be remedied quite easily by changing the INLET port location/angle on the crankshaft to 53deg BTDC (which should give a timing gap of 0.5 deg between TRANSFER CLOSING and INLET OPENING) or 53.5deg BTDC, which should bring the timing to equality.

I would go with the 53 deg BTDC.

Naturally this will also alter the INLET closing point to 21 deg ATDC but, since you are in the sub-piston induction part of the cycle; that should not present any real problem.

This will not alter any of the other port timing.

Having said this

.. There may be some mileage in reducing the sub-piston induction period if you find that you are getting a consistent weak mixture

.. this can be done by making the length of the piston skirt (below the gudgeon pin (wrist pin)) a little longer

. However this can be done at a later date

. if necessary. (Make a new piston).

Keep going my friend, you are almost there. :bow: :bow: :bow:

Best regards.

Sandy ;D ;D ;D