Gazzaleach

Active Member

- Joined

- Jan 11, 2013

- Messages

- 31

- Reaction score

- 9

Hi Guys,

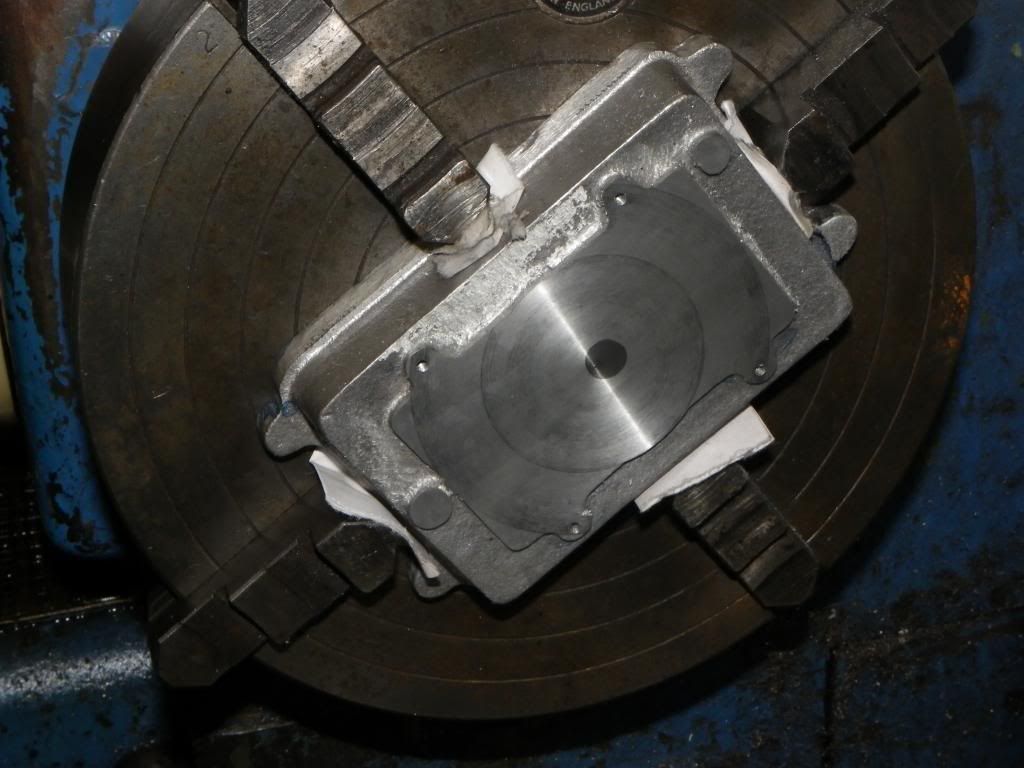

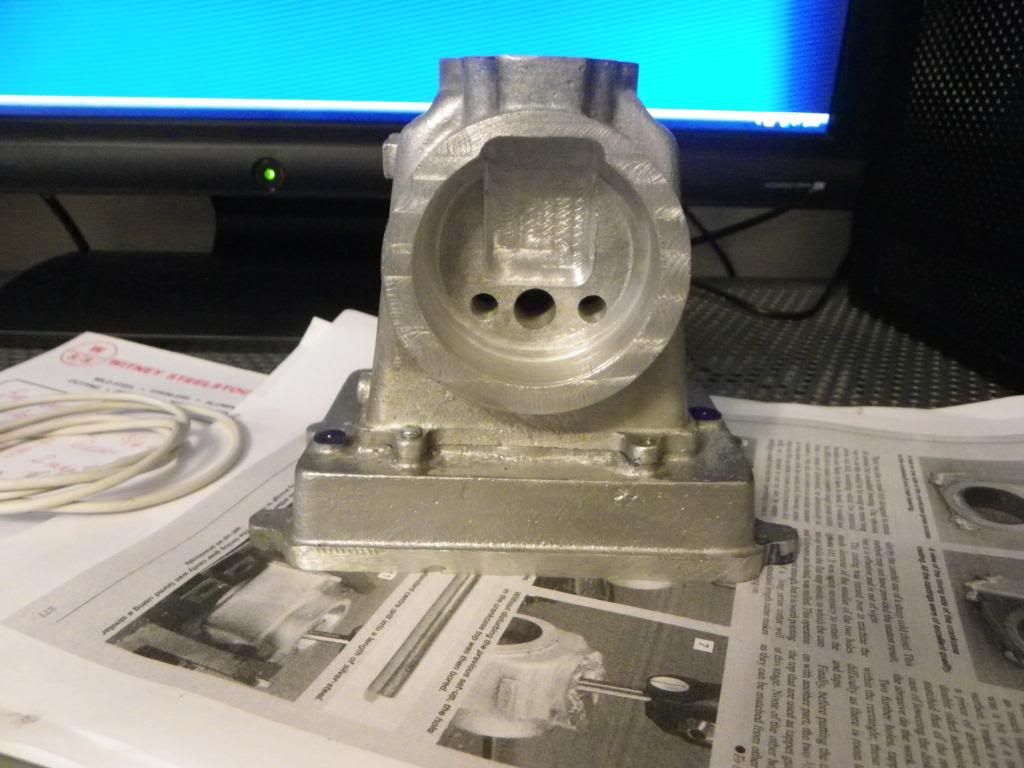

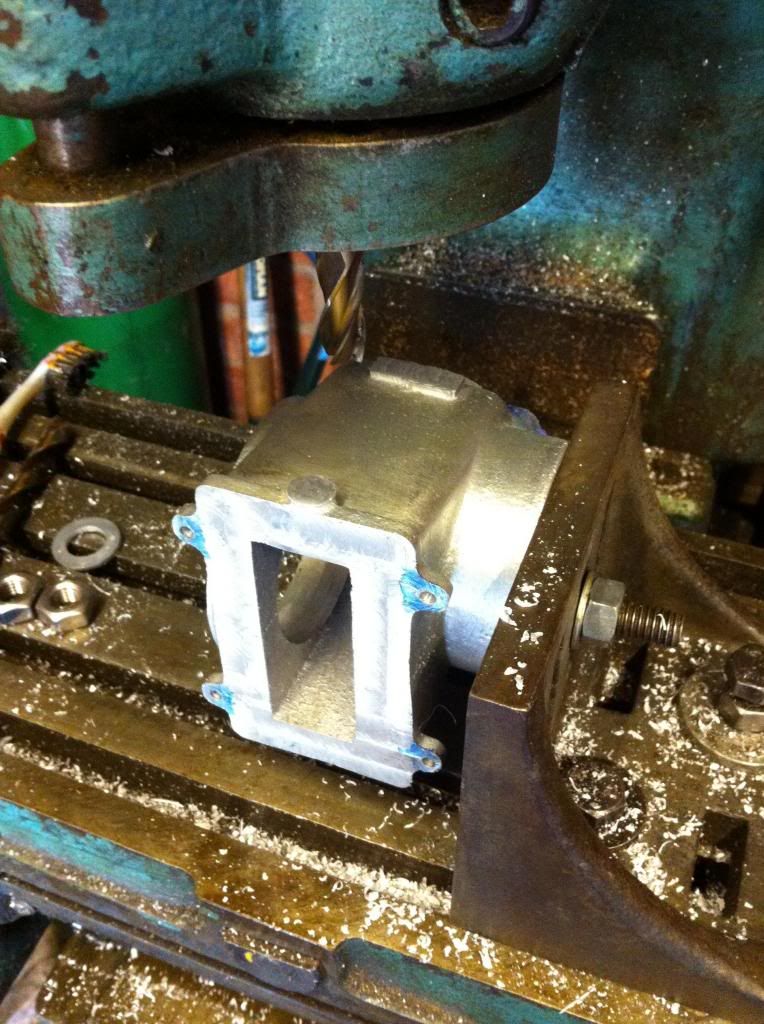

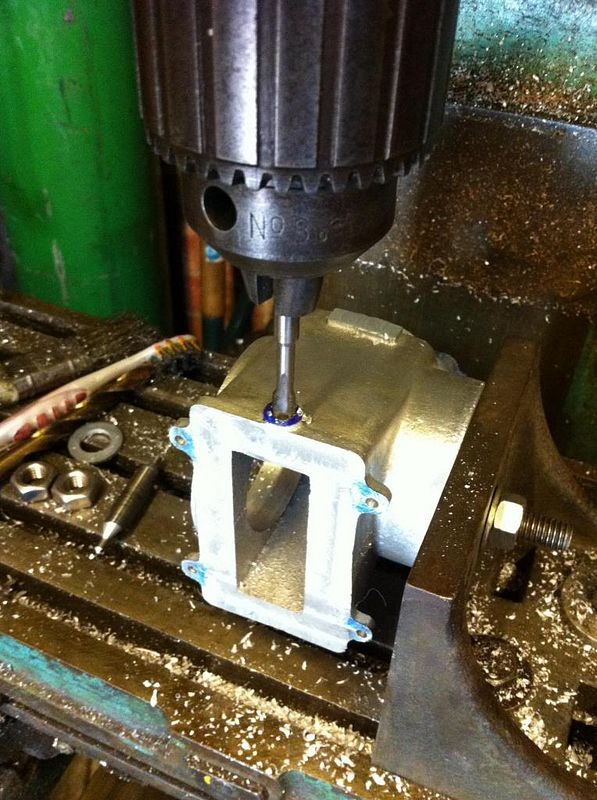

Well my flame eater is almost finished I had to order some better bearings today to complete so while I have a little down time I thought I would dig this little model out which is something I started about 7-8 years ago.

At the time my only machine was a Warco lathe/mill combo so the parts that have been started are going to need a little fettling but this is not going to be a rushed job and will try and do a bit when time allows, Im currently converting all the drawings to metric.

Now the real down side is that over time things have gone missing and this includes the two flywheel castings,con rod casting, and the timing plate casting and also the number two drawing, I spoke to the company that made the kit and they want almost £80 for two flywheel castings which i`m not prepared to pay so I shall be making all the above missing parts from bar stock or plate. They also wont supply me with the missing drawing unless I buy said castings :wall:.

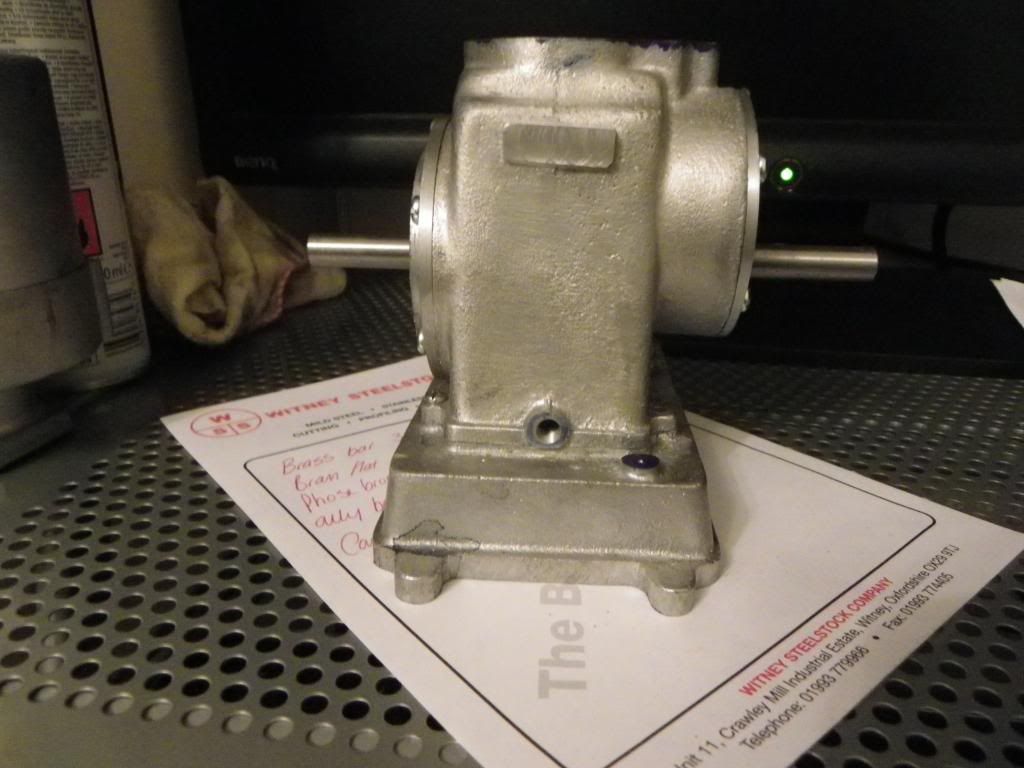

Below are some pictures and again any advice would be great .

cheers Gaz

Well my flame eater is almost finished I had to order some better bearings today to complete so while I have a little down time I thought I would dig this little model out which is something I started about 7-8 years ago.

At the time my only machine was a Warco lathe/mill combo so the parts that have been started are going to need a little fettling but this is not going to be a rushed job and will try and do a bit when time allows, Im currently converting all the drawings to metric.

Now the real down side is that over time things have gone missing and this includes the two flywheel castings,con rod casting, and the timing plate casting and also the number two drawing, I spoke to the company that made the kit and they want almost £80 for two flywheel castings which i`m not prepared to pay so I shall be making all the above missing parts from bar stock or plate. They also wont supply me with the missing drawing unless I buy said castings :wall:.

Below are some pictures and again any advice would be great .

cheers Gaz

Last edited: