You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Team Build 8

- Thread starter dalem9

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Got more parts

. This time from Dale.

. This time from Dale.

Pictures look great, but the parts are even better looking and came with nice fasteners. Thm::bow:

Nice work Dale.

Can't wait to start assembling ... in fact I'm going to start now.

Pat H.

Pictures look great, but the parts are even better looking and came with nice fasteners. Thm::bow:

Nice work Dale.

Can't wait to start assembling ... in fact I'm going to start now.

Pat H.

chucketn

Senior Citizen

Pretty quiet lately, everyone o.k.?

I made a screw plate recommended here and on other forums. I added a nut to each screw and used a dremel type tool to cut the screws to length. Faster and better than my previous method.

Chuck

I made a screw plate recommended here and on other forums. I added a nut to each screw and used a dremel type tool to cut the screws to length. Faster and better than my previous method.

Chuck

my parts are ready to go just gotta send them out.

they will be out this week.

chris

Great news Chris

I like the idea of engraving all the team members but there is just not enough room on the plate (so they can be read, that is!)

So I still don't know what to do.

Anyone else want to update ....stickpoke

Pat H.

Last edited:

- Joined

- Mar 13, 2012

- Messages

- 583

- Reaction score

- 62

Anyone else want to update ....stickpoke

Pat H.

I have the mounting blocks remade except for the mounting holes to screw them to the side frames. I am staying after work tonight to drill those holes.

Once that is done, they need to spend a night in the tumbler to debur, and I'll be able to mail them all out.

I'll probably make a trip to the post office Saturday morning

maverick

Well-Known Member

Uploaded with ImageShack.us

Hello team,

I've received some very nice looking parts and am excited to start assembling them. Pat, the engraving came out great. Did you cut them as a pocket rather than a straight line? Dale, the cylinder is a real jewel and a lot of work I'm sure. I"m still struggling to get enough time to devote to this project. just when I thought I saw light at the end of the tunnel,

it turned out to be a train. Guess I shouldn't complain, work is work.

The crank throws and shafts are done and partly silver soldered, had to order more solder. Flywheel stock is cut and waiting for me and the weekend.

I hope to send some more progress pics soon.

Regards,

Maverick

chucketn

Senior Citizen

If it helps to get all builders on the plate, how about first initial, last name? Or a reference to this thread? If the latter, we could post the list of builders here.

Thanks for the updates, guys.

Chuck

Thanks for the updates, guys.

Chuck

RobinCoulton

Member

- Joined

- Dec 13, 2012

- Messages

- 8

- Reaction score

- 0

Hi everyone , just wonted to say this team build idea you guys have set up is really good .

I would love to get involved with one in the future if possible .

Only problem being I'm in England .

Robin

I would love to get involved with one in the future if possible .

Only problem being I'm in England .

Robin

chucketn

Senior Citizen

Robin, why not organize a team build for members in Great Britain?

Chuck

Chuck

I have the mounting blocks remade except for the mounting holes to screw them to the side frames. I am staying after work tonight to drill those holes.

Once that is done, they need to spend a night in the tumbler to debur, and I'll be able to mail them all out.

I'll probably make a trip to the post office Saturday morning

Brian,

Great ... looking forward to those parts.

Tell me about the tumbler, I have wanted one for some time. Any pictures of it or Model number. Come to think of it ... it's probably a huge commercial one.

Maverick,

Great to hear that your parts are coming along. Looks like they will top notch.

The engraved plate does use pockets. The tool tip is .010" wide the pockets are .017" and up. I used Solidworks but so far have not been able to figure out how to engrave a single line. The CAM needs a edge. Still working on it. But I think in this case the pocket looks better, especially when using a contrasting filler. I plan on spray painting it then wipe the surface to remove the surface paint. Then lightly sand the surface for brush look. Should look nice ... well, the sample did anyway.

Chuck,

Still working on ... the key may be to use single lines rather than a pocket ... just have to figure out a way to that. :wall: What I really wanted was Name and Location ... so that the viewer would appreciate the teams wide geographical area.

Thanks for the update,

Pat H.

ninefinger

Well-Known Member

Hi Team,

I must apologize too for my tardiness, just as I figured out how to machine these parts I was sent out of town on business. I'm back now and plan on taking a day off to recover from travel etc so I should get some good shop time in and hopefully make some real progress. The parts I've received so far have been fantastic, I am aiming to get my quality up to match that which I've received.

Regards,

Mike

I must apologize too for my tardiness, just as I figured out how to machine these parts I was sent out of town on business. I'm back now and plan on taking a day off to recover from travel etc so I should get some good shop time in and hopefully make some real progress. The parts I've received so far have been fantastic, I am aiming to get my quality up to match that which I've received.

Regards,

Mike

chucketn

Senior Citizen

Not to worry, Mike. Life can get in the way sometimes. Keep it fun! That's important.

Chuck

Chuck

Last edited:

- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

Hi Guys,its getting a bit boring to us interested outsiders.I know its exciting for all you guys

receiving your items but is anyone assembling yet ? How about some photos.I have been watching

this thread for a while and this engine is on my to do list.Please post some photos BAZMAK

receiving your items but is anyone assembling yet ? How about some photos.I have been watching

this thread for a while and this engine is on my to do list.Please post some photos BAZMAK

- Joined

- Mar 13, 2012

- Messages

- 583

- Reaction score

- 62

Hey Pat,

The tumbler is nothing special. It is a small rock tumbler I got as a birthday present 30-some years ago. I've carried it on through various stages of my life, and used it for all sorts of uses other that what it was intended for.

I'm not an expert on tumbling, but I have a few different types of media for deburring and polishing. It doesn't work miracles, but its handy for lots of small parts like these.

The tumbler is nothing special. It is a small rock tumbler I got as a birthday present 30-some years ago. I've carried it on through various stages of my life, and used it for all sorts of uses other that what it was intended for.

I'm not an expert on tumbling, but I have a few different types of media for deburring and polishing. It doesn't work miracles, but its handy for lots of small parts like these.

- Joined

- Mar 13, 2012

- Messages

- 583

- Reaction score

- 62

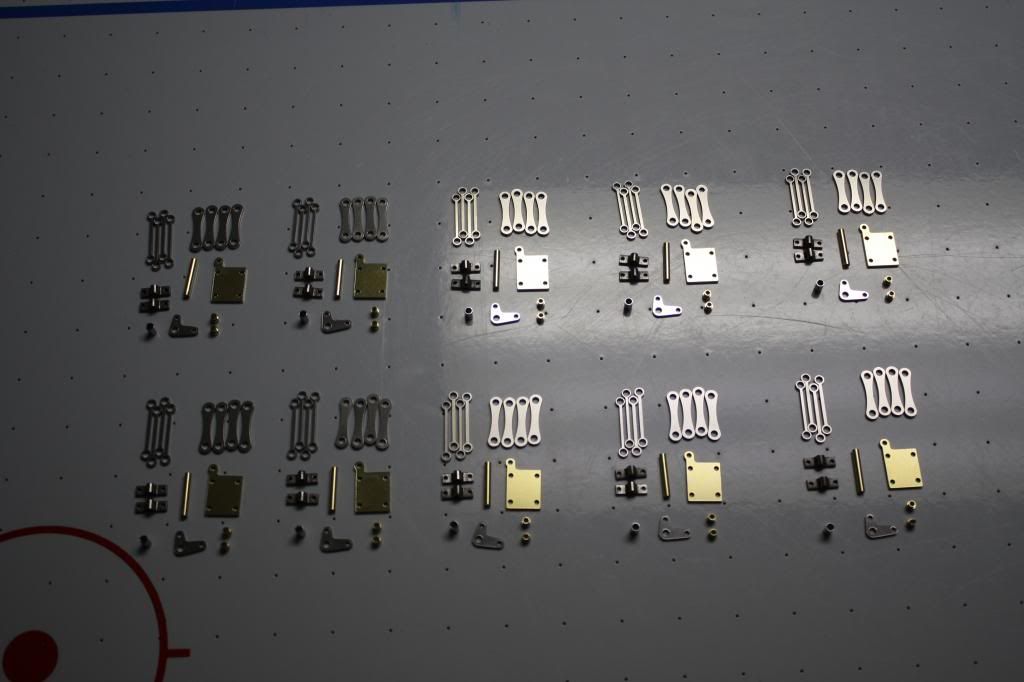

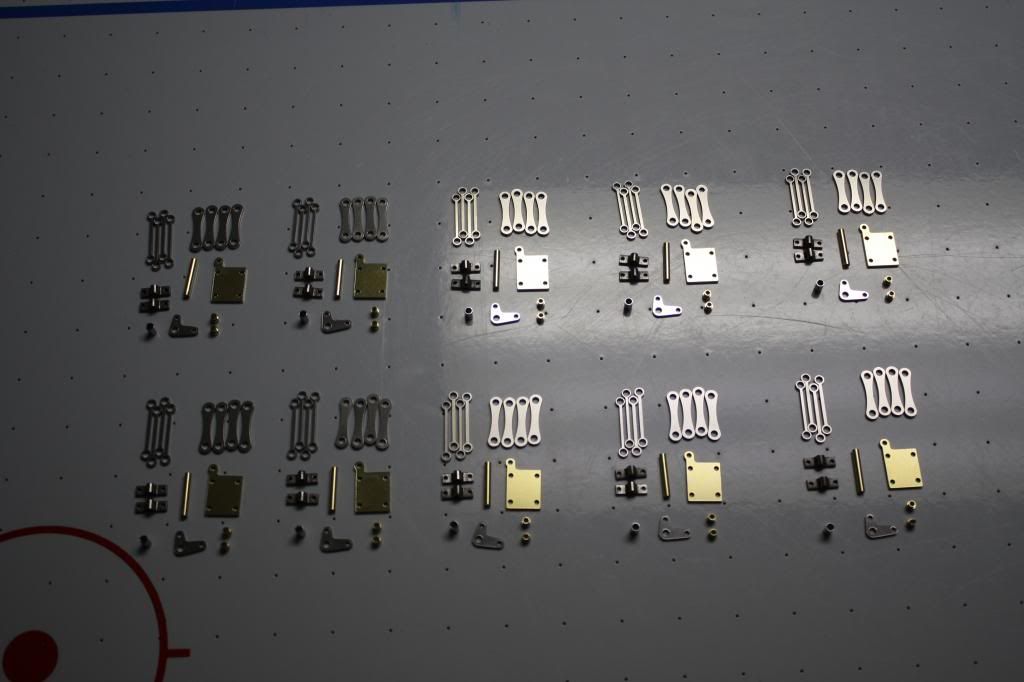

Well, my parts are away. Hopefully you will all receive them soon. I took one last photo of them, and in honor of our Canadian builders, I laid them all out on the kids' air-hockey table

There were a couple of blemished parts that I had intended to keep for myself. However when I started packing them all up, I forgot to search them out. Someone will end up with a steam chest cover with a scratch that should polish out. Someone else (Well, I hope it is someone else) will get a bell crank link that has a bit of a booger on the edge. I apologize

I feel kind of bad. I had a ton of parts to make, but they are pretty insignificant looking when compared to the bigger parts. I hope everyone is satisfied with what they get.

There were a couple of blemished parts that I had intended to keep for myself. However when I started packing them all up, I forgot to search them out. Someone will end up with a steam chest cover with a scratch that should polish out. Someone else (Well, I hope it is someone else) will get a bell crank link that has a bit of a booger on the edge. I apologize

I feel kind of bad. I had a ton of parts to make, but they are pretty insignificant looking when compared to the bigger parts. I hope everyone is satisfied with what they get.

Brian,

Your parts look great and no apologies necessary. Those little things can be fixed, no one should expert perfect parts.

I made what 30 parts ... you made 160. I think it's harder to make lots and lots of little parts then a few big parts.

Looking forward to getting them.

Pat H.

Your parts look great and no apologies necessary. Those little things can be fixed, no one should expert perfect parts.

I made what 30 parts ... you made 160. I think it's harder to make lots and lots of little parts then a few big parts.

Looking forward to getting them.

Pat H.

- Joined

- May 14, 2011

- Messages

- 683

- Reaction score

- 185

Brian Got your parts today ,Look great . Thanks Dale

Similar threads

- Replies

- 59

- Views

- 4K

- Replies

- 0

- Views

- 221